Production Management System 是生产管理系统的英文表达。

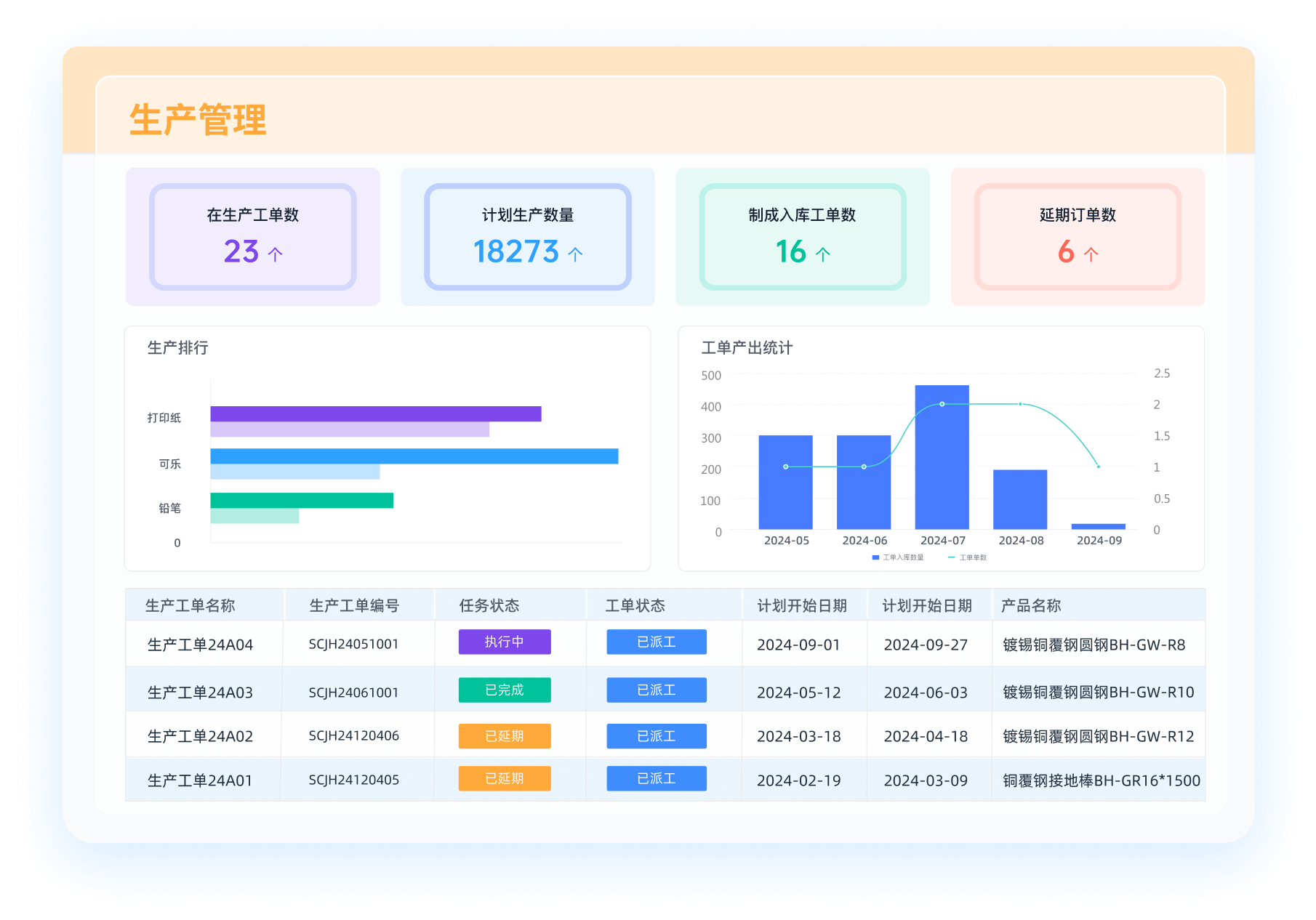

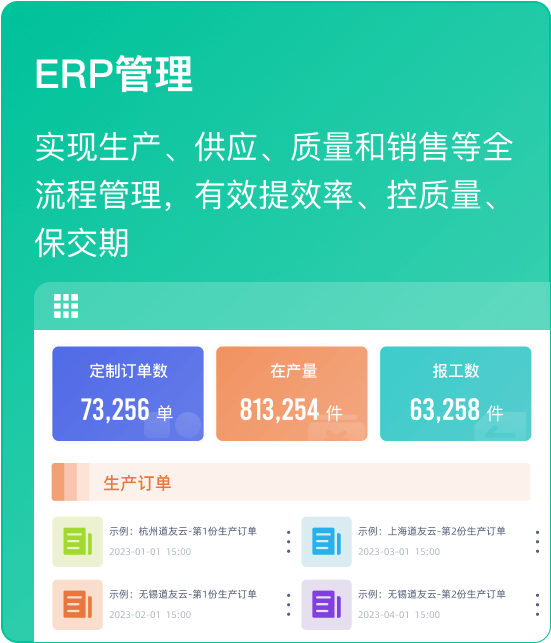

1、 Production Management System (PMS) 是一种集成的软件解决方案,它有助于优化生产计划、监控生产过程、管理物料和资源,并提高整体生产效率。这种系统为制造企业提供了多种功能模块,从生产计划、物料管理、质量控制到设备维护等。

一、PRODUCTION MANAGEMENT SYSTEM 的核心功能

- 生产计划与排程

- 物料管理

- 质量控制

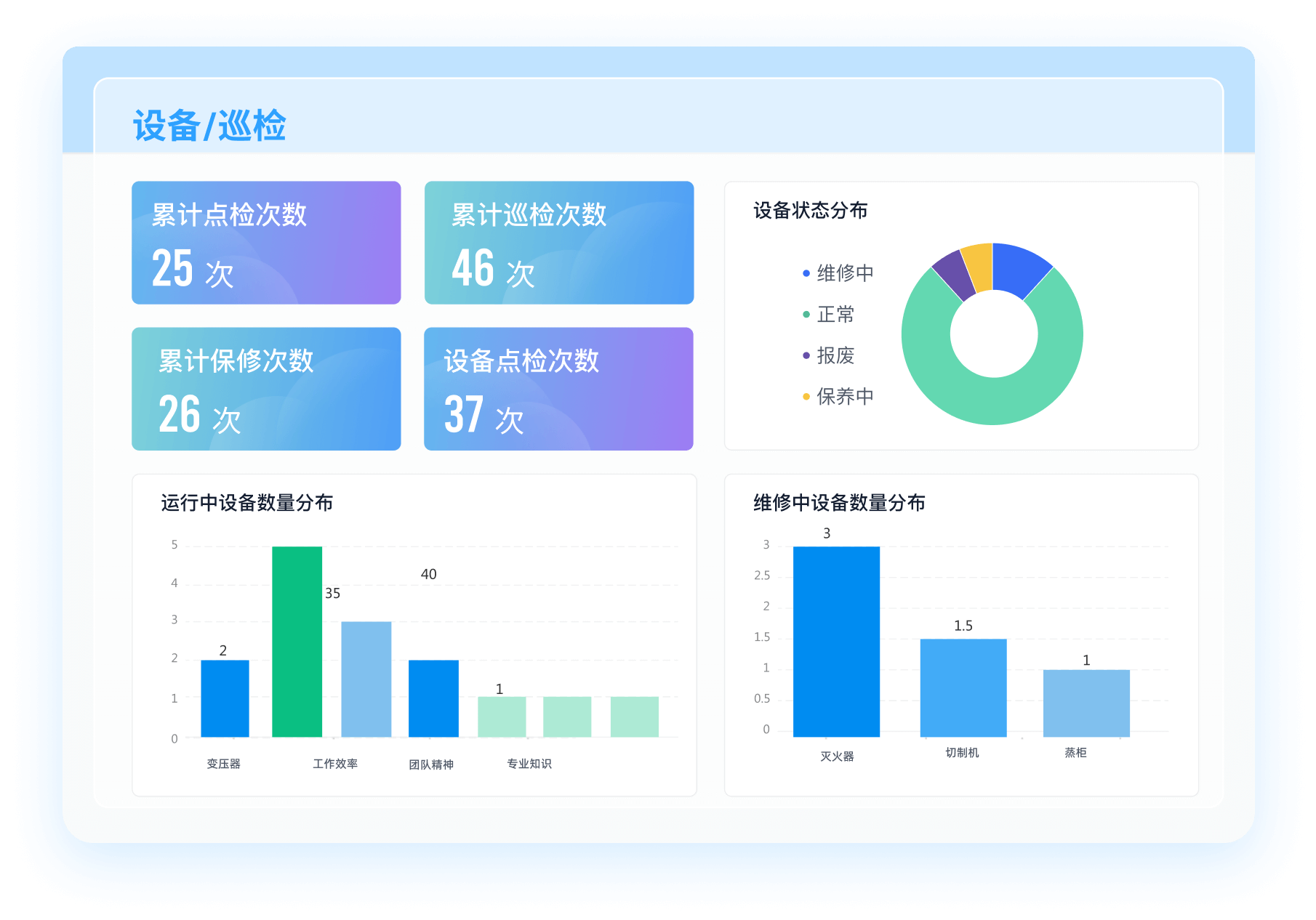

- 设备维护

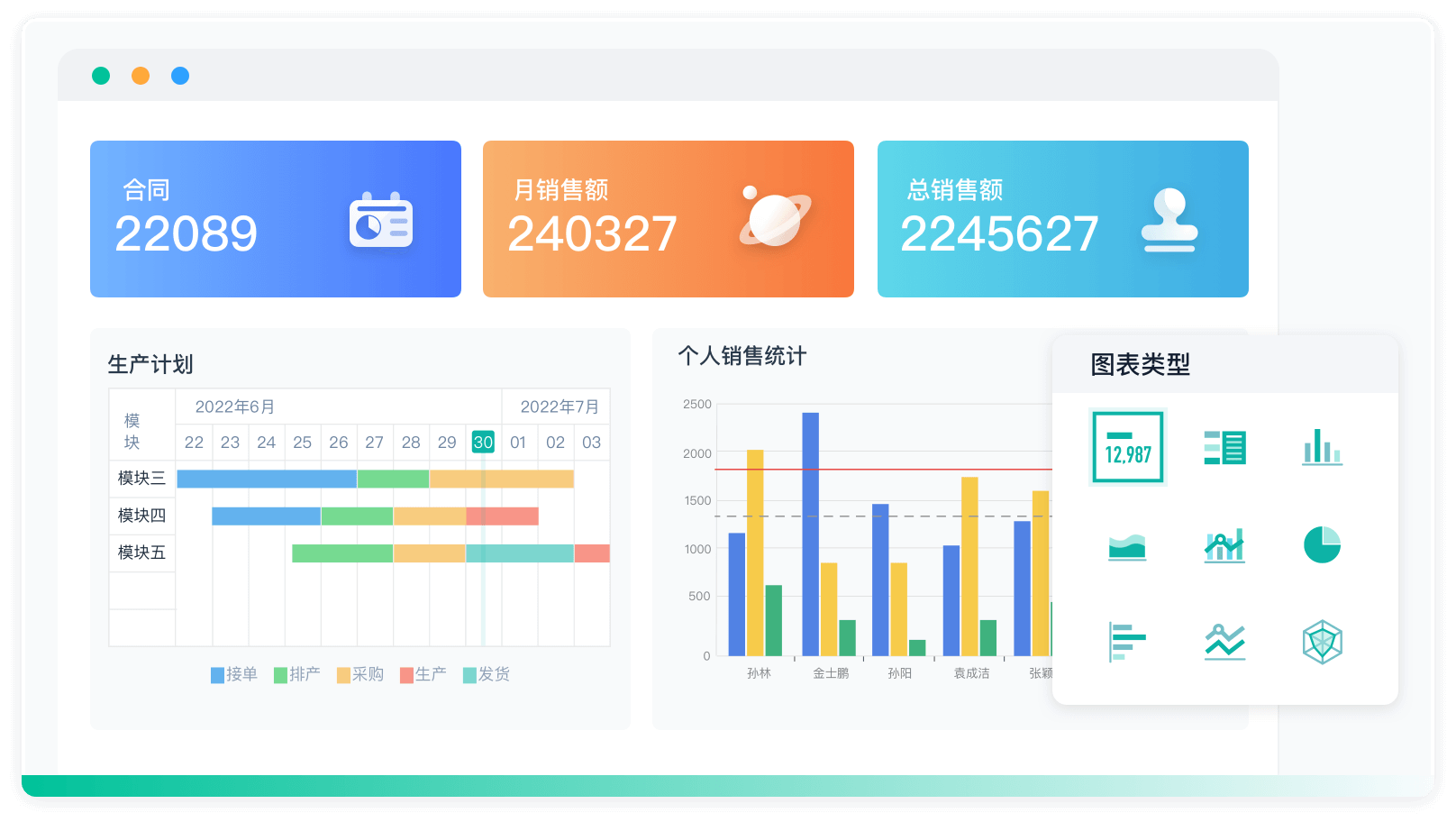

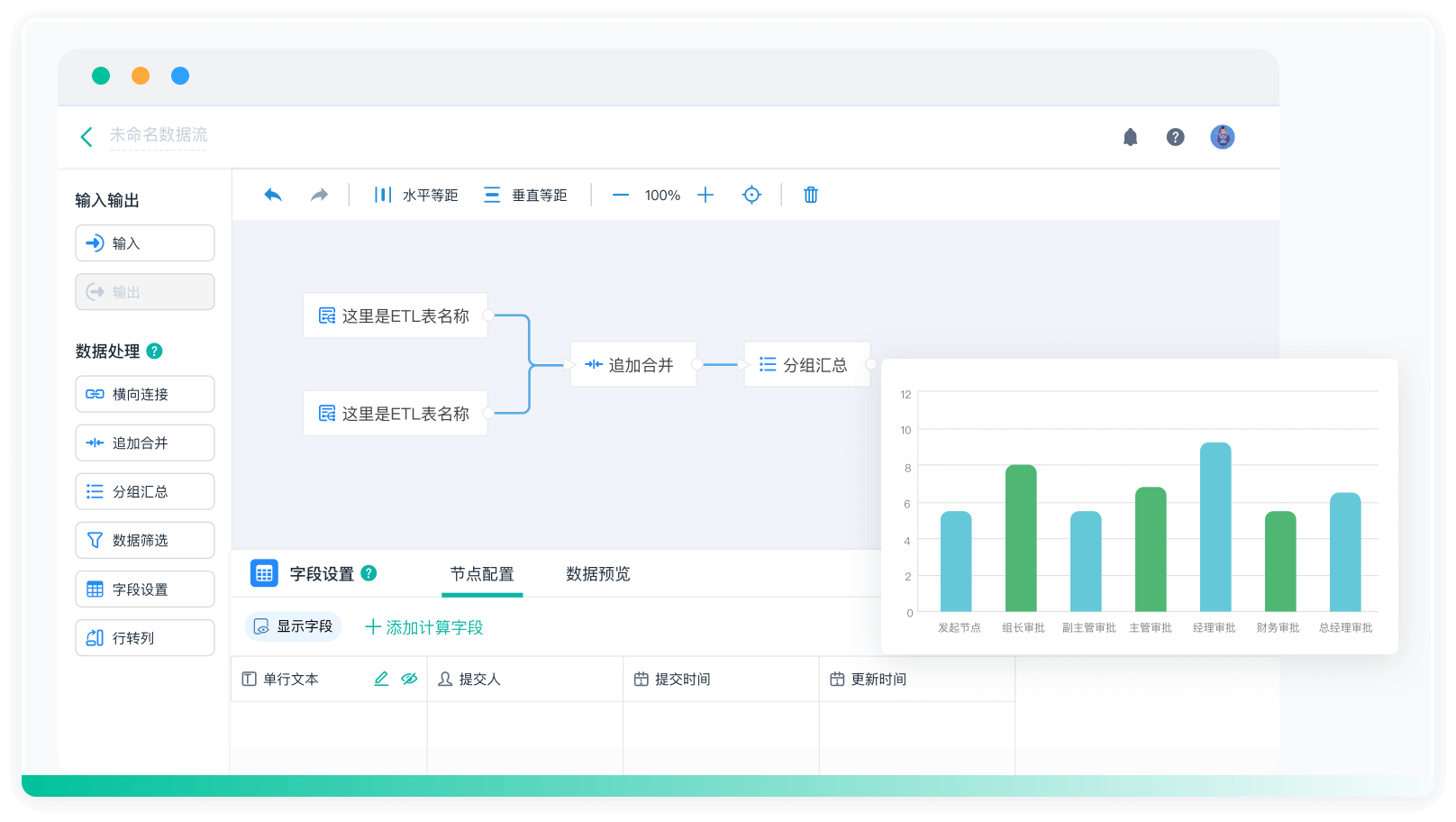

- 数据分析与报表

生产计划与排程

生产管理系统的生产计划与排程模块可以帮助企业根据订单需求和生产能力,合理安排生产任务。这不仅能有效减少生产中的等待时间,还能确保资源的最佳利用。

二、PRODUCTION MANAGEMENT SYSTEM 的优势

- 提高生产效率

- 减少库存成本

- 提升产品质量

- 优化资源利用

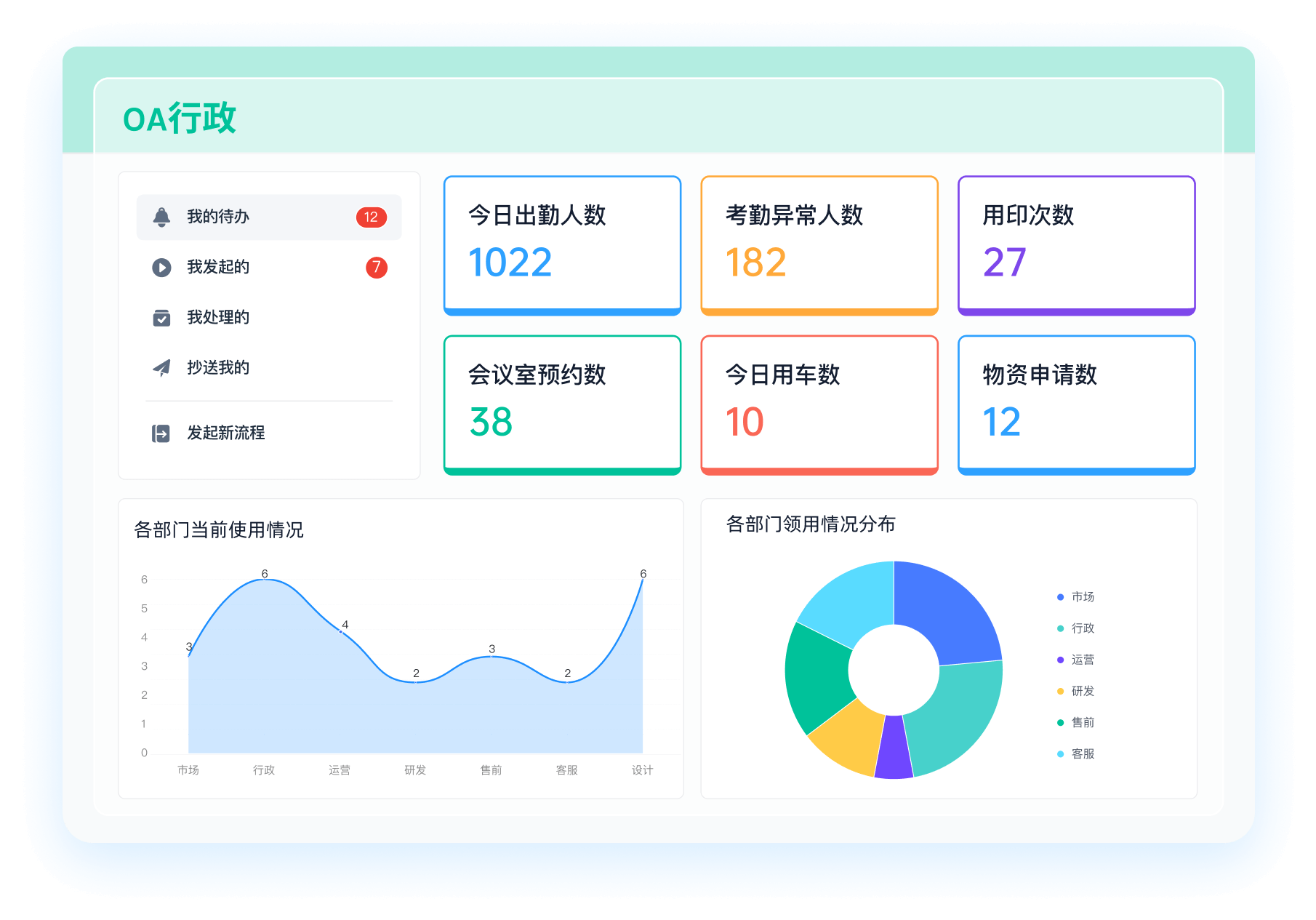

- 实时数据监控

三、如何选择合适的PRODUCTION MANAGEMENT SYSTEM

- 功能匹配性

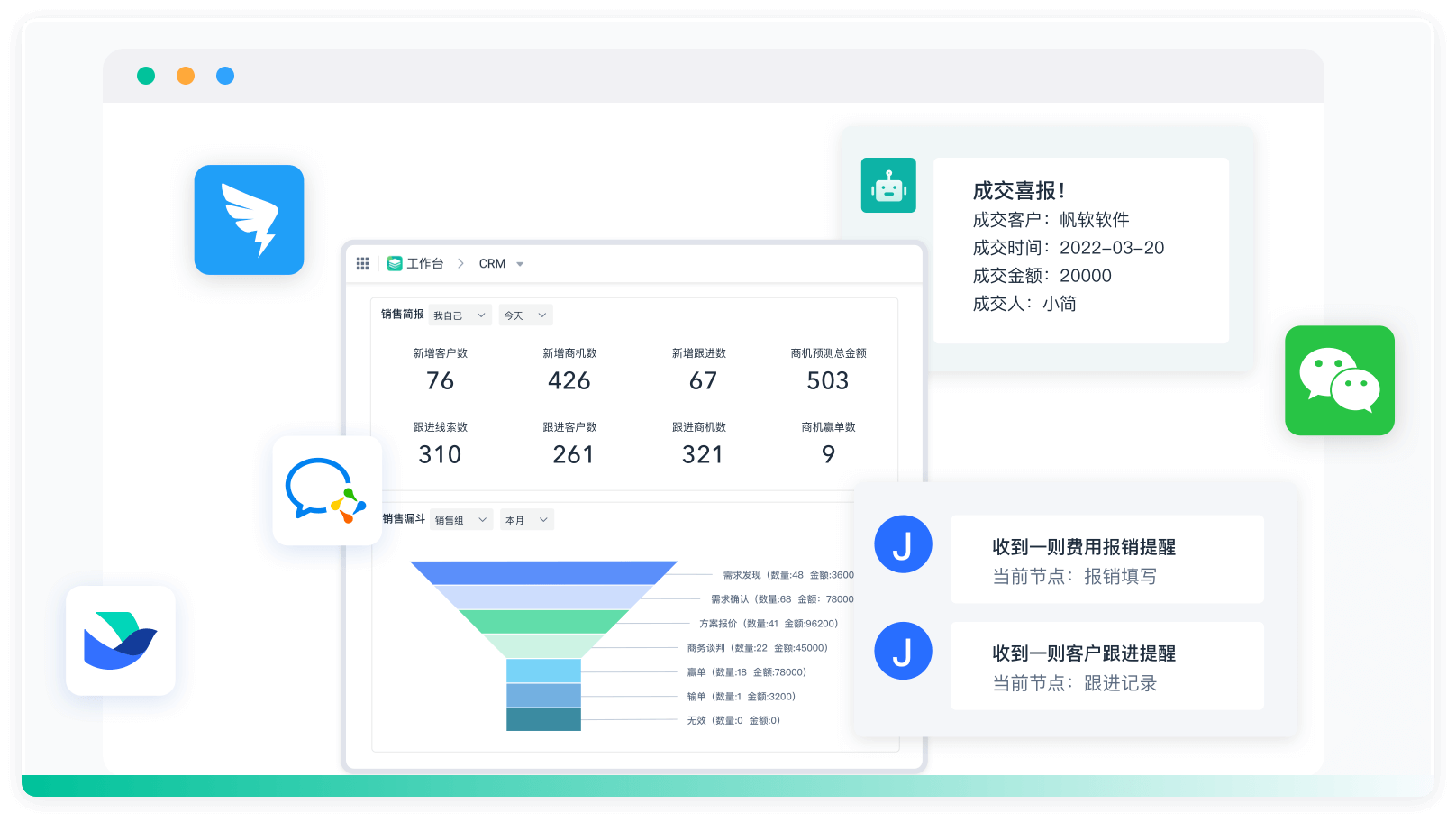

- 系统集成能力

- 用户友好性

- 技术支持与服务

- 成本与预算

功能匹配性

选择生产管理系统时,首先需要评估其功能是否能够满足企业的具体需求。不同的企业有不同的生产流程和管理要求,因此需要选择一个能够灵活适应这些需求的系统。

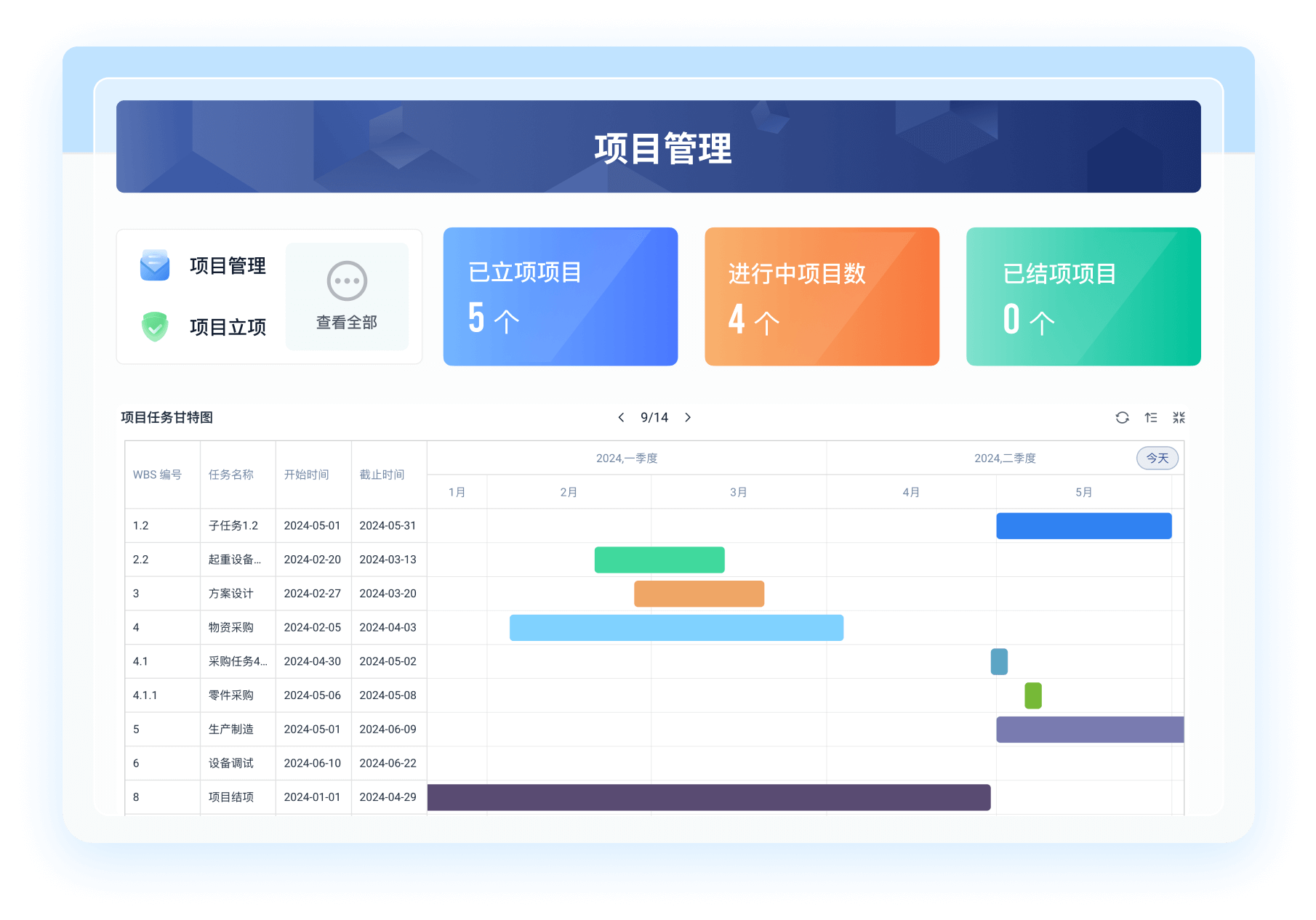

四、实施PRODUCTION MANAGEMENT SYSTEM 的步骤

- 需求分析

- 系统选型

- 项目规划

- 系统实施

- 培训与测试

五、成功案例分析

- 案例一:某汽车制造企业

- 案例二:某电子产品制造企业

案例一:某汽车制造企业

某汽车制造企业通过实施生产管理系统,实现了生产计划的精确排程和实时监控,生产效率提高了20%,库存成本减少了15%。

六、未来发展趋势

- 智能制造

- 物联网应用

- 大数据分析

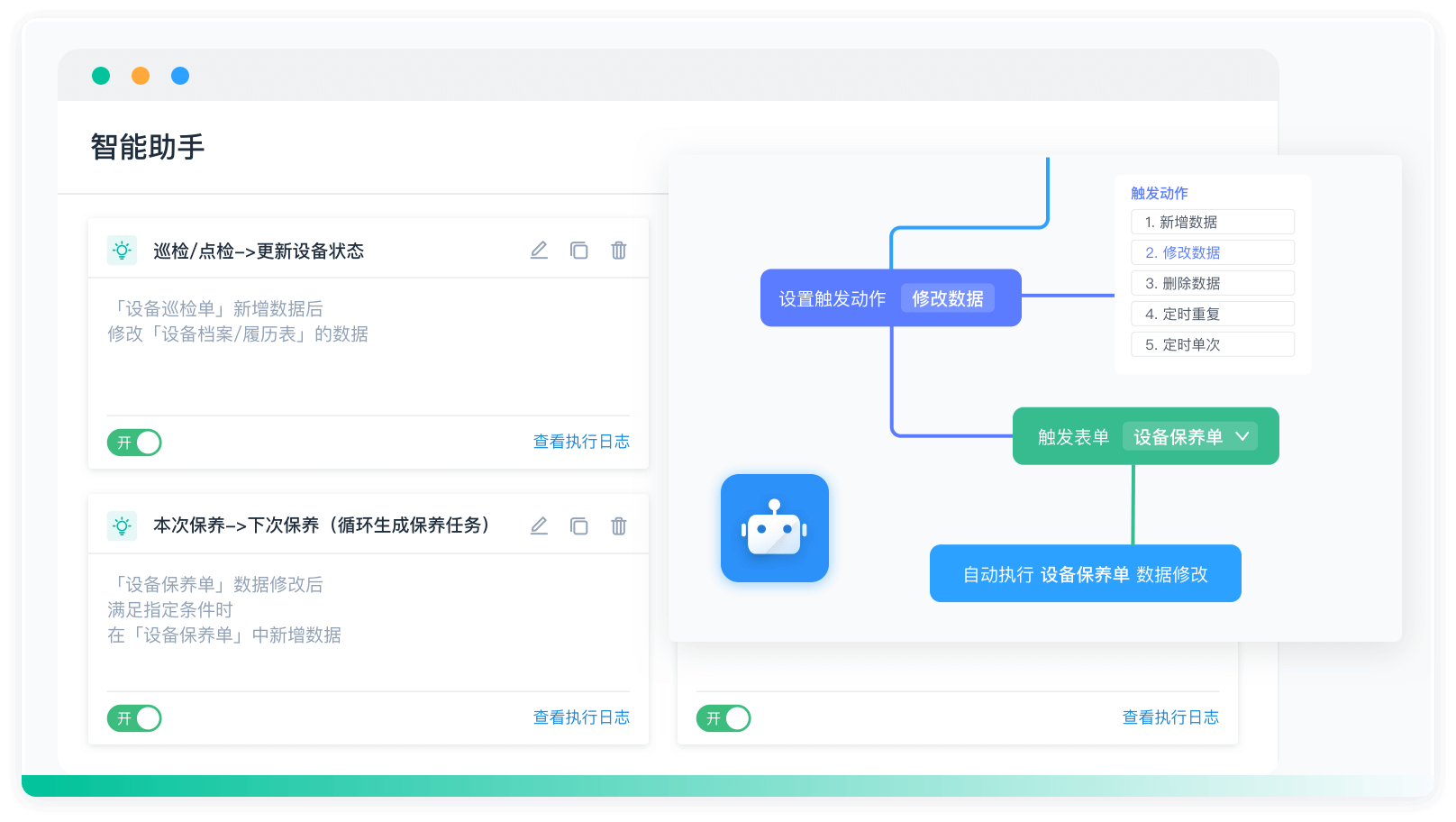

- 人工智能应用

总结

生产管理系统是现代制造企业提升生产效率和管理水平的重要工具。通过合理选择和实施生产管理系统,企业可以实现生产过程的全面优化,提高市场竞争力。企业应根据自身需求,选择功能匹配、操作简单、支持全面的系统,确保实施效果最大化。

相关问答FAQs:

What is the English term for "生产管理系统"?

The English term for "生产管理系统" is "Production Management System." This refers to a comprehensive set of processes and tools that organizations utilize to manage their manufacturing operations efficiently. A Production Management System encompasses various elements such as planning, scheduling, monitoring, and controlling production processes, ensuring that resources are utilized effectively to meet production goals.

How does a Production Management System benefit manufacturing companies?

A Production Management System offers numerous advantages to manufacturing companies. One of the primary benefits is enhanced efficiency. By automating scheduling and tracking of production activities, organizations can minimize downtime and optimize resource allocation. This leads to improved throughput and reduced operational costs.

Another significant advantage is better quality control. These systems often include tools for monitoring production quality in real-time, enabling quick identification and rectification of issues before they escalate. This proactive approach helps maintain high product standards and reduces waste.

Additionally, a Production Management System facilitates data-driven decision-making. By providing detailed analytics and reporting tools, managers can gain insights into production performance, identify bottlenecks, and forecast demand more accurately. This results in a more agile manufacturing process that can quickly adapt to changing market conditions.

What features should one look for in a Production Management System?

When selecting a Production Management System, several key features should be considered to ensure it meets the specific needs of the organization.

-

Real-Time Monitoring: Look for systems that provide real-time visibility into production processes. This allows for immediate tracking of progress and quick adjustments as needed.

-

Inventory Management: An integrated inventory management feature is essential for keeping track of raw materials and finished goods, ensuring that production runs smoothly without interruptions due to stock shortages.

-

Scheduling and Planning Tools: Effective scheduling tools help optimize production timelines, allowing for better management of resources and minimizing delays.

-

Reporting and Analytics: Robust reporting capabilities enable detailed analysis of production metrics, helping businesses identify trends and make informed decisions.

-

Quality Control Integration: A system that incorporates quality control features ensures that products meet specifications and reduces the risk of defects.

-

User-Friendly Interface: A system with an intuitive design can significantly enhance user adoption and reduce training time for employees.

In summary, choosing a Production Management System with these features can greatly enhance operational efficiency and overall productivity in manufacturing environments.

阅读时间:8 分钟

阅读时间:8 分钟  浏览量:9847次

浏览量:9847次

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》