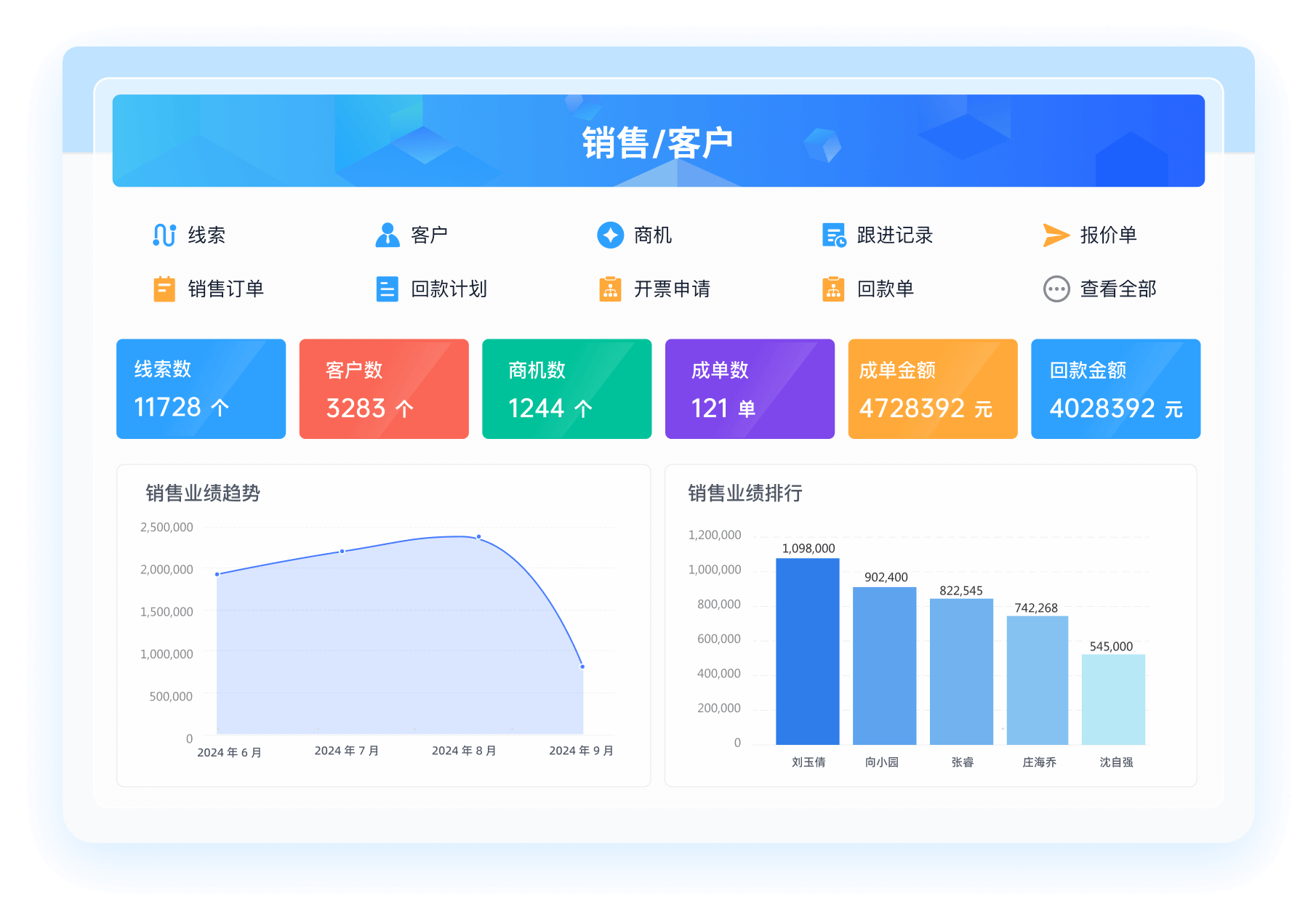

Production Management System(生产管理系统)是指用于规划、控制和优化生产过程的软件系统。它涵盖了从原材料采购到产品制造再到成品交付的整个生产周期。

一、WHAT IS A PRODUCTION MANAGEMENT SYSTEM?

A Production Management System (PMS) is a software solution designed to manage and optimize manufacturing processes. It ensures that production operations are efficient, cost-effective, and meet quality standards. Here are the key benefits of using a PMS:

- Improved Efficiency: PMS automates various production processes, reducing manual intervention and errors. This leads to faster production cycles and increased output.

- Cost Reduction: By optimizing resource utilization and minimizing waste, a PMS helps in reducing production costs.

- Quality Control: PMS ensures that all products meet quality standards by providing real-time monitoring and control of production processes.

- Better Inventory Management: PMS helps in managing inventory levels, ensuring that materials are available when needed and reducing excess stock.

- Enhanced Decision Making: With real-time data and analytics, managers can make informed decisions to improve production processes.

二、KEY FEATURES OF A PRODUCTION MANAGEMENT SYSTEM

A comprehensive Production Management System typically includes the following features:

-

Planning and Scheduling:

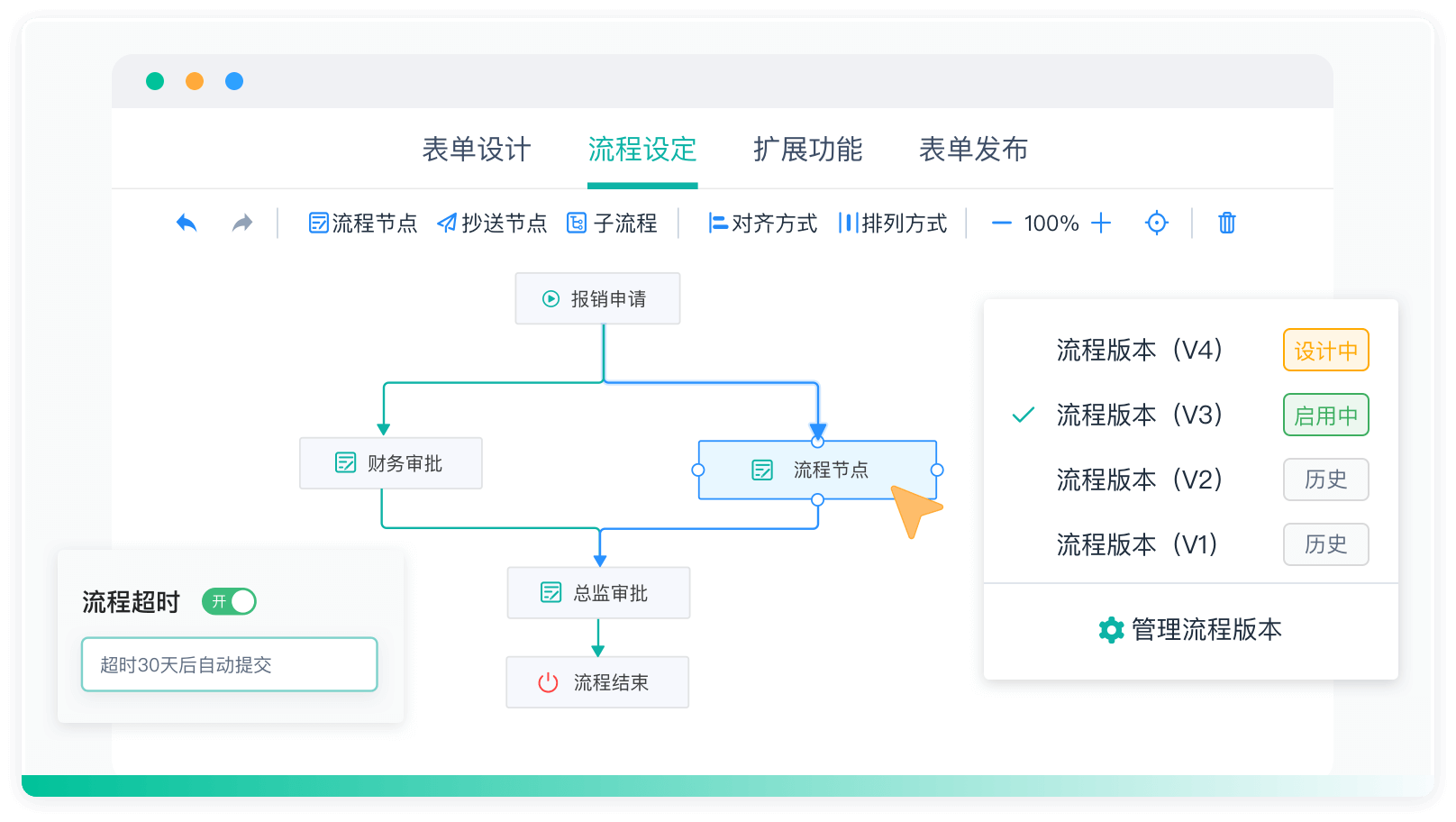

- Production Planning: Define production goals, timelines, and resource allocation.

- Scheduling: Create detailed production schedules to ensure timely completion of tasks.

-

Resource Management:

- Material Management: Track and manage raw materials and inventory.

- Workforce Management: Allocate and monitor labor resources.

-

Process Control:

- Real-time Monitoring: Monitor production processes in real-time to identify and address issues promptly.

- Quality Assurance: Implement quality control measures to ensure product standards are met.

-

Data and Analytics:

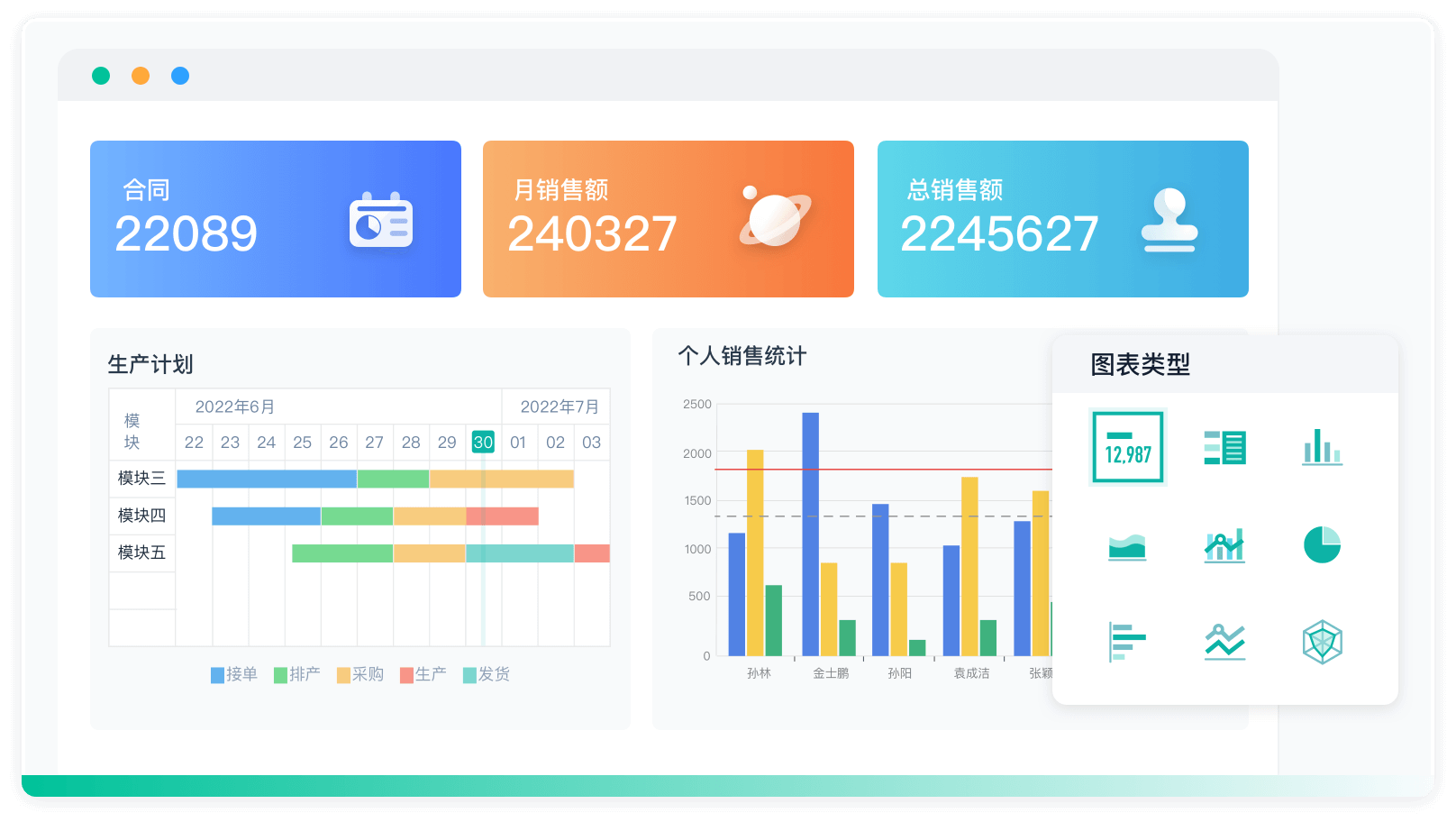

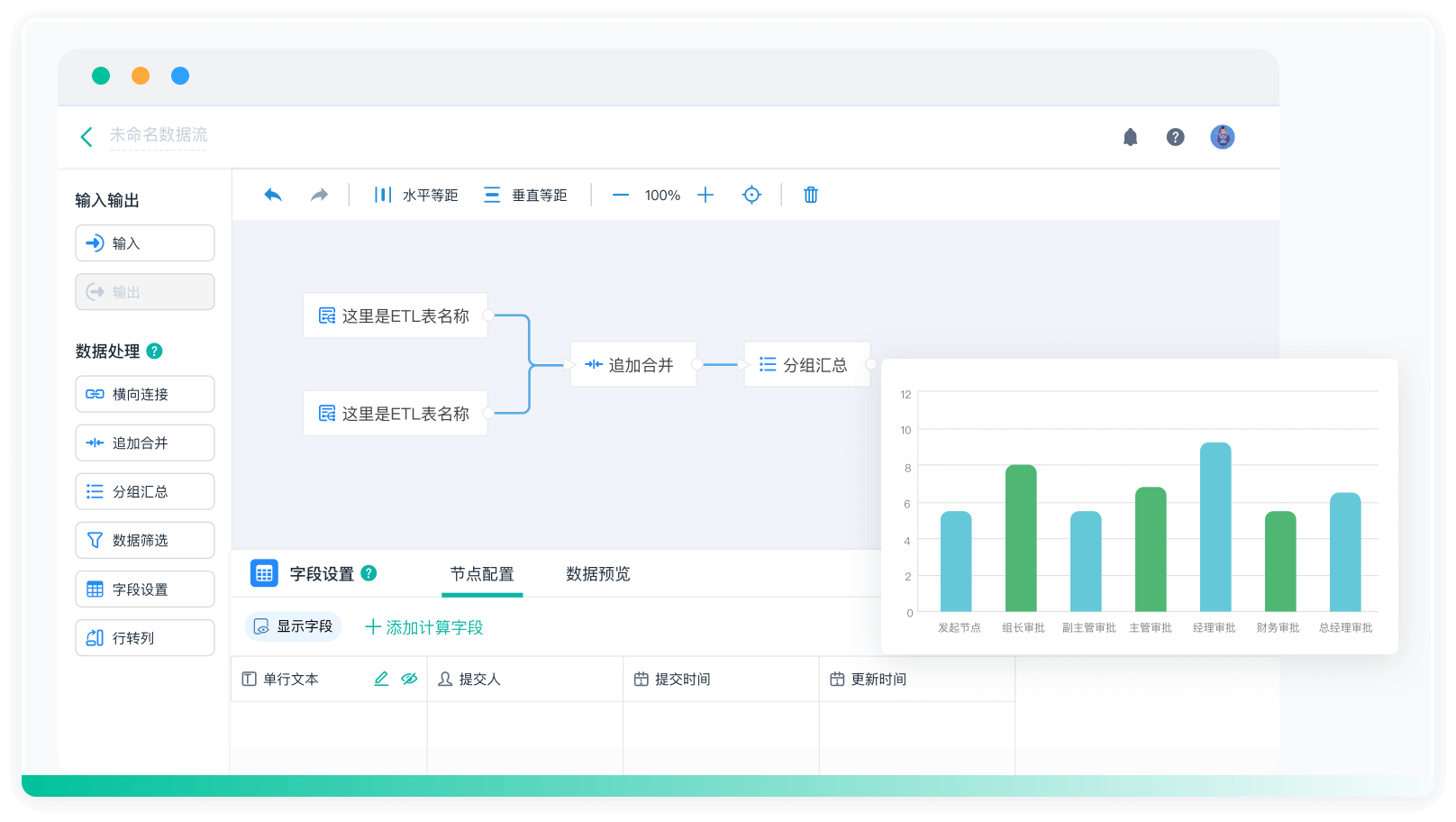

- Data Collection: Gather data from various production processes for analysis.

- Analytics: Analyze data to identify trends, inefficiencies, and areas for improvement.

三、IMPLEMENTING A PRODUCTION MANAGEMENT SYSTEM

Implementing a PMS involves several steps to ensure successful integration and operation:

-

Assessment and Planning:

- Evaluate current production processes and identify areas for improvement.

- Define goals and objectives for the PMS implementation.

-

System Selection:

- Research and select a PMS that meets your specific requirements.

- Ensure the system is scalable and can integrate with existing systems.

-

Customization and Integration:

-

Training and Deployment:

- Train employees on how to use the new system.

- Deploy the system in phases to minimize disruption.

四、REAL-WORLD EXAMPLES OF PMS USAGE

Several industries have successfully implemented PMS to enhance their production processes:

-

Automotive Industry:

- PMS is used to manage complex production lines, ensuring timely delivery of vehicles.

- Real-time monitoring helps in maintaining high-quality standards.

-

Food and Beverage Industry:

- PMS helps in managing perishable inventory and ensuring compliance with food safety regulations.

- Production scheduling ensures efficient use of resources and minimal waste.

-

Pharmaceutical Industry:

- PMS ensures strict adherence to manufacturing protocols and regulatory compliance.

- Quality control measures are critical to ensuring the safety and efficacy of products.

五、FUTURE TRENDS IN PRODUCTION MANAGEMENT SYSTEMS

As technology advances, PMS is expected to evolve with new features and capabilities:

-

Artificial Intelligence and Machine Learning:

- AI and ML can be used to predict production issues and optimize processes.

- These technologies can enhance decision-making with advanced data analytics.

-

Internet of Things (IoT):

- IoT devices can provide real-time data from production equipment, improving monitoring and maintenance.

- IoT can help in tracking inventory and raw materials more accurately.

-

Cloud Computing:

- Cloud-based PMS offers scalability and flexibility, allowing businesses to access the system from anywhere.

- It also reduces the need for on-premises infrastructure and maintenance.

六、CONCLUSION

In conclusion, a Production Management System is essential for modern manufacturing operations. It improves efficiency, reduces costs, and ensures product quality. By implementing a PMS, businesses can better manage their production processes and stay competitive in the market. For further information on production management systems, consider researching specific software solutions that align with your business needs.

相关问答FAQs:

1. 什么是生产管理系统?

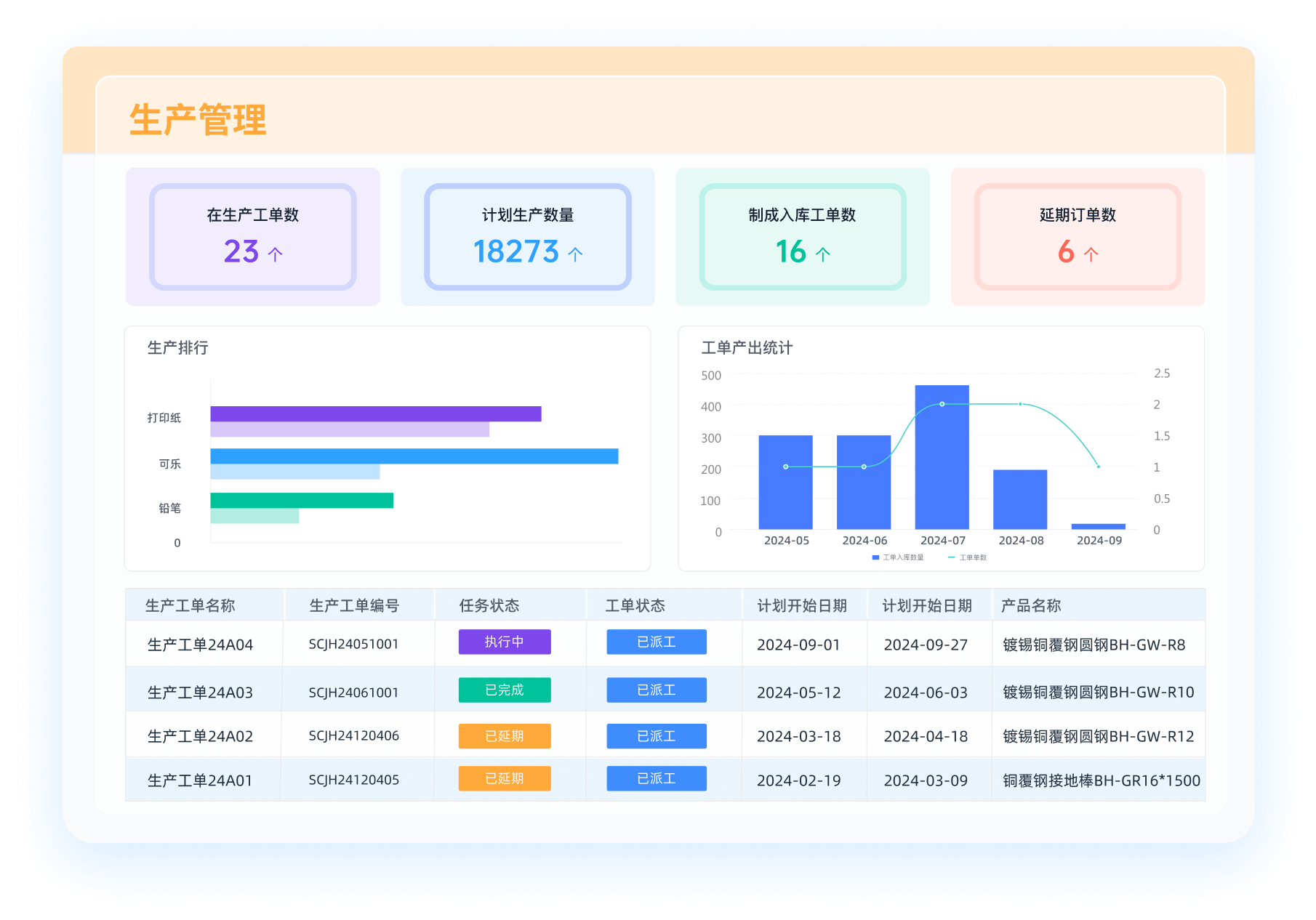

生产管理系统(Production Management System)是一个用于计划、协调和控制生产活动的软件工具。它的主要目标是提高生产效率,降低成本,并确保产品质量。通过实时数据分析和监控,生产管理系统可以帮助企业优化资源配置,减少生产周期,并提高响应市场需求的能力。它通常包括库存管理、工艺规划、生产调度、质量控制等模块,使得企业能够更加高效地运作。

2. 生产管理系统的主要功能有哪些?

生产管理系统通常具备以下几个核心功能:

- 生产计划与调度:帮助企业制定详细的生产计划,合理安排生产时间和资源,以确保及时交付。

- 库存管理:实时监控原材料和成品的库存情况,自动生成补货建议,防止缺货或过剩。

- 质量控制:通过设定质量标准和检测流程,确保生产过程中的每一个环节都符合质量要求,减少不合格品的产生。

- 数据分析与报告:提供实时数据分析工具,帮助管理层做出更为科学的决策,生成各类生产报告,提升透明度。

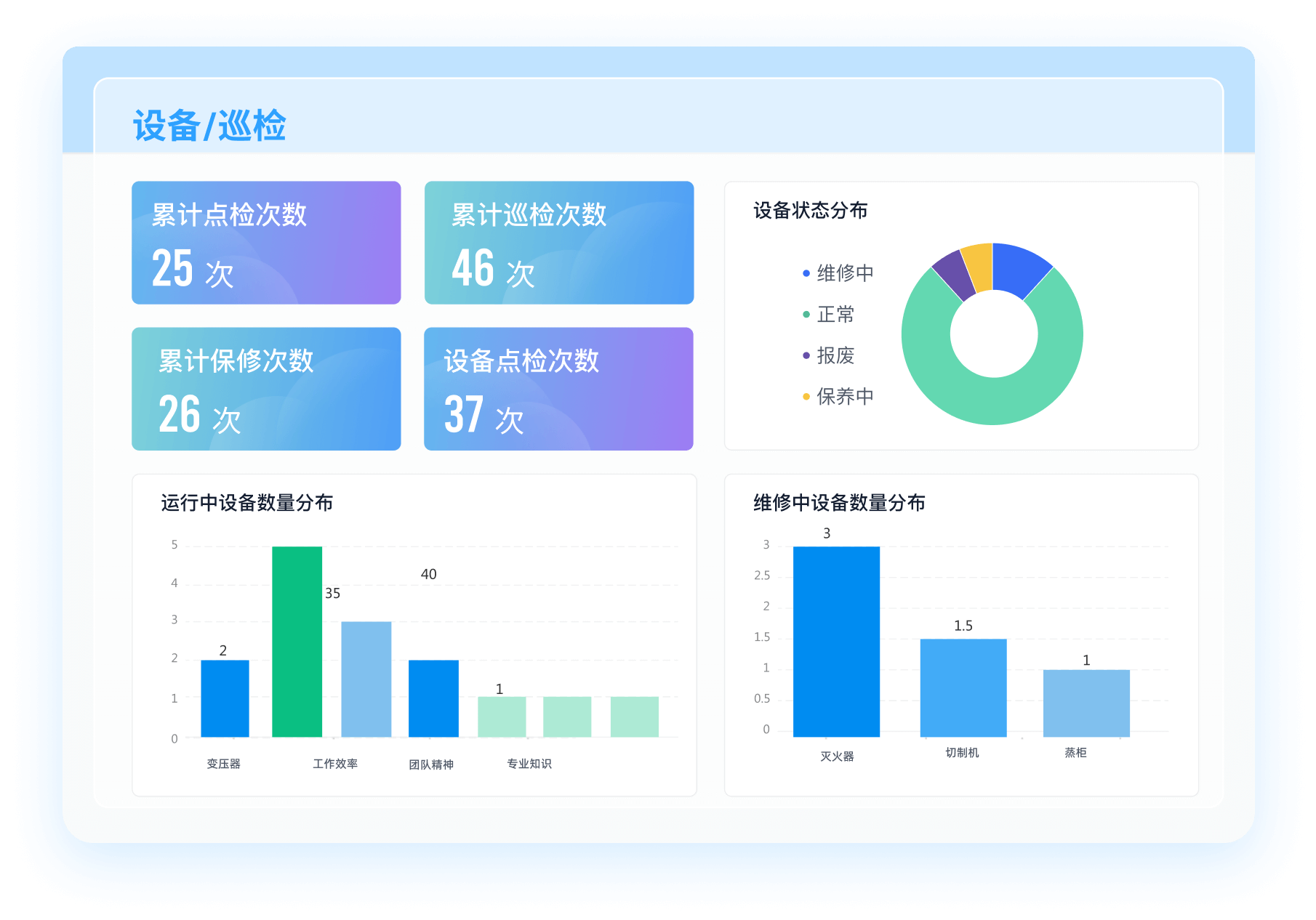

- 设备管理:监控生产设备的状态,进行维护和保养,确保设备的高效运转。

3. 企业如何选择合适的生产管理系统?

选择合适的生产管理系统需要考虑多个因素:

- 企业规模与需求:小型企业可能只需要基本的生产调度和库存管理功能,而大型企业则需要更多定制化的解决方案。

- 系统集成能力:考虑与现有系统(如财务、ERP等)的兼容性,确保不同系统之间的数据流通。

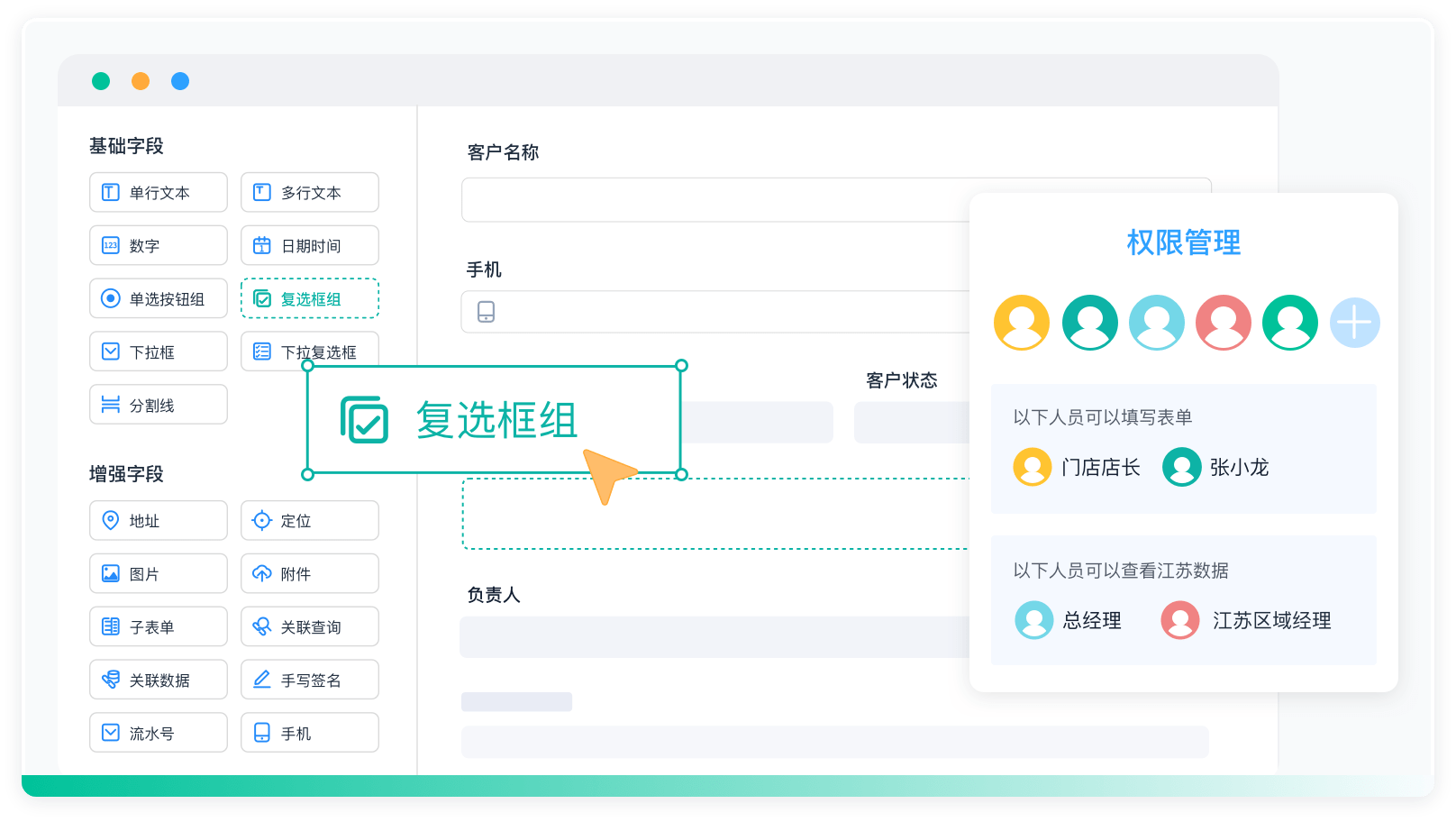

- 用户友好性:系统的界面和操作是否简洁易用,是否需要大量的培训才能上手。

- 技术支持与服务:供应商提供的技术支持和服务质量至关重要,确保在出现问题时能够及时获得帮助。

- 成本:不仅要考虑软件的购买成本,还要评估后续的维护费用和升级成本,确保在预算范围内。

选择合适的生产管理系统是一个复杂的过程,但通过综合考虑以上因素,可以帮助企业找到最适合自己的解决方案。

简道云WMS仓库管理系统模板:

无需下载,在线即可使用: https://s.fanruan.com/q6mjx;

阅读时间:8 分钟

阅读时间:8 分钟  浏览量:933次

浏览量:933次

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》