仓管要如何管理仓库呢英语

-

Title: Warehouse Management: Strategies and Procedures

Introduction:

Warehouse management plays a crucial role in ensuring the smooth running of operations and the overall success of a business. Effective warehouse management involves the proper organization, storage, and distribution of goods within the warehouse. In this guide, we will discuss the methods and procedures that warehouse managers can implement to efficiently manage a warehouse.-

Proper Inventory Management:

- Implement an inventory management system: Utilize software programs or warehouse management systems to track inventory levels, monitor stock movements, and generate reports.

- Conduct regular stock checks: Perform cycle counts or physical inventories to ensure that actual stock levels match the system records.

- Utilize barcode or RFID technology: Use technology to accurately track and manage inventory, reducing errors and improving efficiency.

-

Efficient Layout and Storage:

- Optimize warehouse layout: Arrange storage areas to facilitate easy access and movement of goods. Utilize racks, shelves, and bins to maximize storage space.

- Implement ABC analysis: Classify items based on their importance and frequency of movement. Store high-demand items in easily accessible locations.

- Utilize FIFO and LIFO techniques: Implement first-in, first-out (FIFO) or last-in, first-out (LIFO) methods to ensure proper rotation of stock and prevent product expiry.

-

Streamlined Pick-and-Pack Process:

- Implement a pick-and-pack strategy: Organize picking routes, batch orders, and optimize packing processes to minimize picking time and increase productivity.

- Utilize automated picking systems: Implement technologies such as pick-to-light, voice picking, or automated guided vehicles to improve picking accuracy and efficiency.

- Conduct regular training: Train warehouse staff on efficient picking and packing techniques to reduce errors and increase speed.

-

Effective Warehouse Safety:

- Create a safe working environment: Ensure compliance with safety regulations, provide proper training to staff on safe handling of goods, and maintain a clean and organized workspace.

- Conduct regular safety audits: Inspect warehouse facilities, equipment, and processes to identify potential hazards and address safety concerns promptly.

- Invest in safety equipment: Provide personal protective equipment, safety signs, barriers, and other safety measures to prevent accidents and injuries in the warehouse.

-

Continuous Improvement and Performance Monitoring:

- Set performance metrics: Establish key performance indicators (KPIs) such as order fulfillment rates, inventory accuracy, and on-time delivery to measure warehouse performance.

- Analyze data and trends: Use data analytics and reports to identify bottlenecks, inefficiencies, and areas for improvement in warehouse operations.

- Implement continuous improvement initiatives: Encourage feedback from staff, implement process improvements, and regularly review and adjust warehouse management strategies to optimize performance.

Conclusion:

Effective warehouse management requires a combination of strategic planning, efficient processes, and a focus on continuous improvement. By implementing proper inventory management, optimizing storage, streamlining pick-and-pack processes, ensuring warehouse safety, and monitoring performance, warehouse managers can successfully manage their warehouses and contribute to the overall success of the business.1年前 -

-

Warehouse management plays a critical role in ensuring the smooth operation of a warehouse and effective control of inventory. In this process, the warehouse manager is responsible for overseeing all activities within the warehouse, including receiving, storing, and distributing goods. Here are some key points on how warehouse management can be effectively carried out:

-

Effective Planning and Organization: Warehouse managers need to create a detailed plan for the layout of the warehouse and the allocation of space for different products. This includes setting up storage systems, shelving, and labeling to ensure easy access to items.

-

Inventory Control: Maintaining accurate inventory records is crucial in warehouse management. This involves keeping track of stock levels, conducting regular stock counts, and implementing a system for reordering products when necessary.

-

Efficient Receiving and Shipping Processes: Developing streamlined processes for receiving incoming goods and shipping out products is essential for warehouse efficiency. This includes checking the quality and quantity of incoming goods, as well as packing and labeling items for outgoing shipments.

-

Safety and Compliance: Warehouse managers must prioritize safety in the workplace by following all health and safety regulations. This includes providing training to staff on safe handling of goods, proper use of equipment, and emergency procedures.

-

Technology Integration: Implementing warehouse management systems (WMS) and other technologies can help streamline operations and improve accuracy. WMS software can assist in inventory tracking, order processing, and optimizing storage space.

-

Staff Training and Development: Investing in training for warehouse staff can enhance productivity and efficiency. Providing ongoing development opportunities can help employees improve their skills and adapt to new technologies and processes.

-

Performance Monitoring: Regularly monitoring key performance indicators (KPIs) such as order accuracy, on-time delivery, and inventory turnover can help warehouse managers identify areas for improvement and make informed decisions.

-

Continuous Improvement: Warehouse management is an ongoing process that requires constant evaluation and refinement. By seeking feedback from staff, analyzing data, and implementing changes, warehouse managers can continuously improve operations.

In conclusion, effective warehouse management involves strategic planning, organization, inventory control, safety compliance, technology integration, staff training, performance monitoring, and continuous improvement. By focusing on these key areas, warehouse managers can optimize operations, maximize efficiency, and ensure the smooth functioning of the warehouse.

1年前 -

-

Warehouse Management refers to the process of organizing, controlling, and overseeing the operations in a warehouse to ensure efficient storage and movement of goods. Effective warehouse management is crucial for optimizing inventory levels, minimizing costs, and improving overall productivity. Below are some key strategies for warehouse management:

-

Efficient Layout Design: The first step in warehouse management is to design an efficient layout that maximizes the use of available space. This involves organizing storage racks, shelving units, and aisles in a way that facilitates smooth movement of goods and easy access for picking and packing operations.

-

Inventory Control: Keeping track of inventory levels is essential for ensuring efficient warehouse operations. Implementing an inventory management system can help warehouse managers monitor stock levels, track inventory movements, and prevent stockouts or overstock situations. Regular inventory audits and cycle counts can also help in maintaining accurate inventory records.

-

Material Handling: Choosing the right material handling equipment is crucial for optimizing warehouse operations. Forklifts, pallet jacks, conveyor belts, and automated guided vehicles (AGVs) are some common tools used for moving goods within the warehouse. Proper training for warehouse staff on how to use these equipment safely and efficiently is also important.

-

Order Fulfillment: Streamlining the order fulfillment process can help reduce order processing times and improve customer satisfaction. Implementing efficient picking strategies such as batch picking, zone picking, or wave picking can help optimize order picking processes. Utilizing barcode scanning or RFID technology can also help in reducing picking errors and increasing accuracy.

-

Technology Integration: Leveraging technology tools such as a Warehouse Management System (WMS) can greatly enhance warehouse management efficiency. A WMS can help automate tasks such as inventory tracking, order processing, and scheduling, leading to cost savings and improved productivity. Integrating a WMS with other systems such as ERP software or transportation management systems can also help in achieving seamless operations across the supply chain.

In conclusion, effective warehouse management involves implementing a combination of strategies related to layout design, inventory control, material handling, order fulfillment, and technology integration. By optimizing warehouse operations through these strategies, warehouse managers can improve efficiency, reduce costs, and meet customer demands effectively.

1年前 -

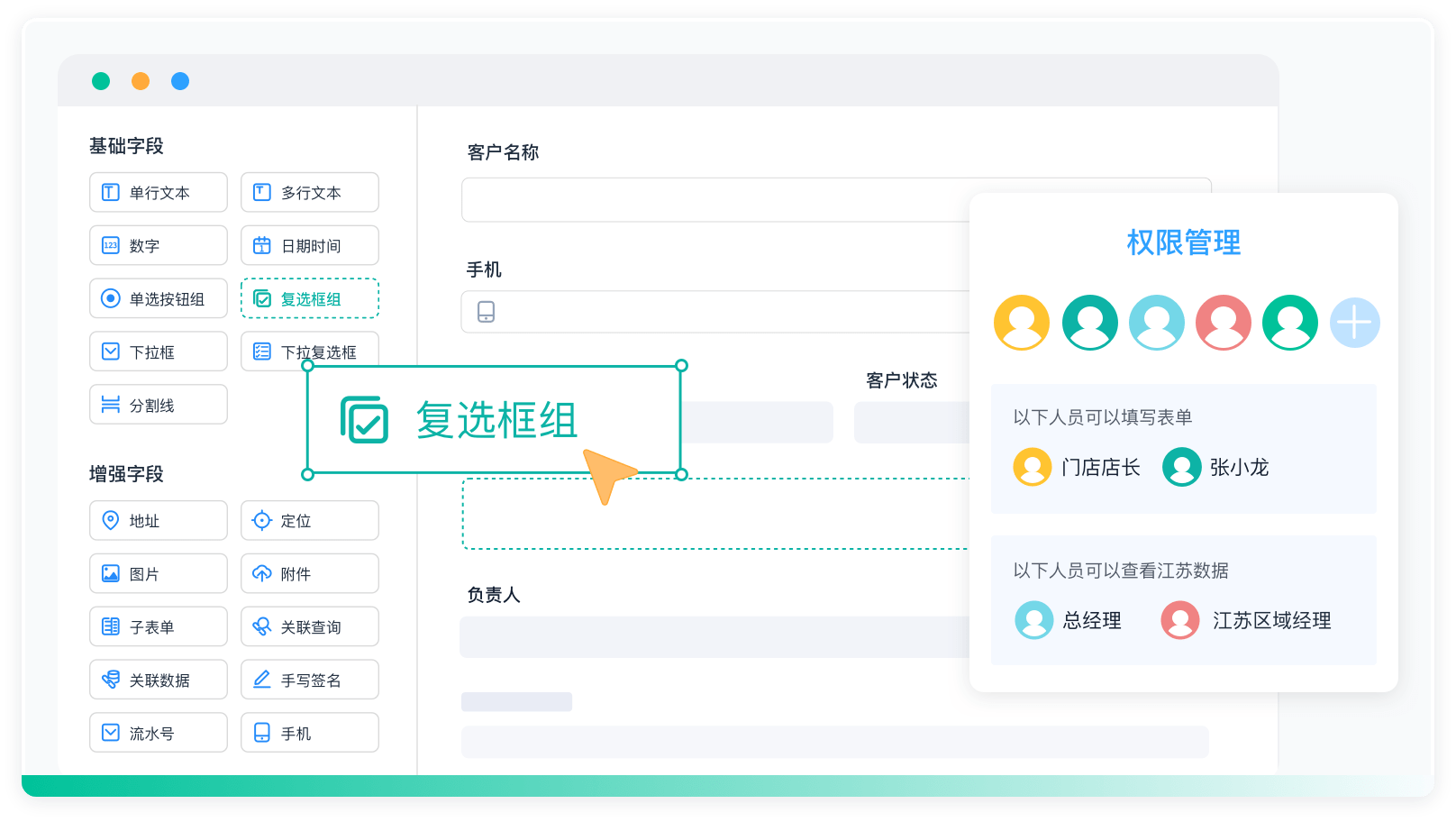

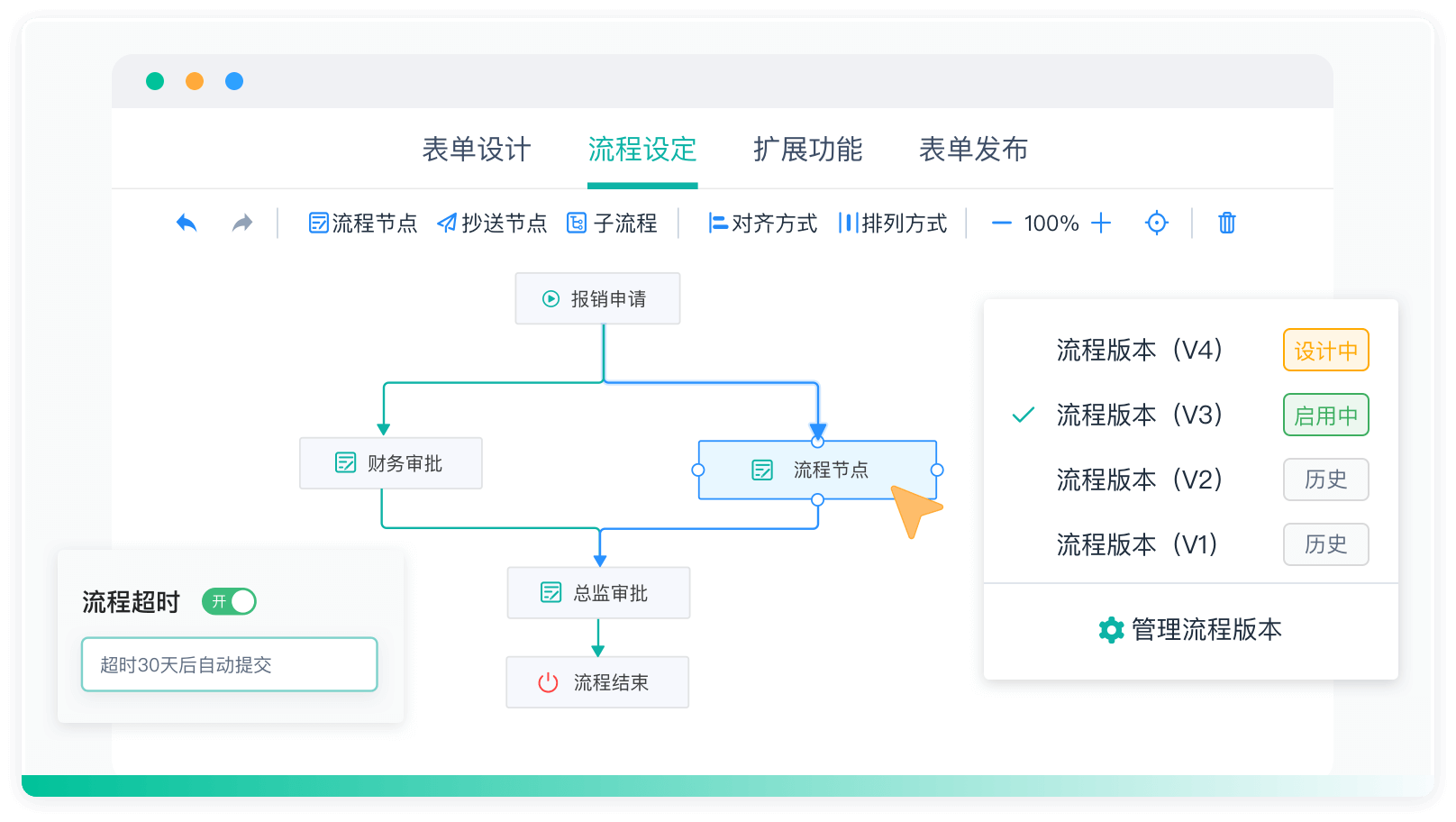

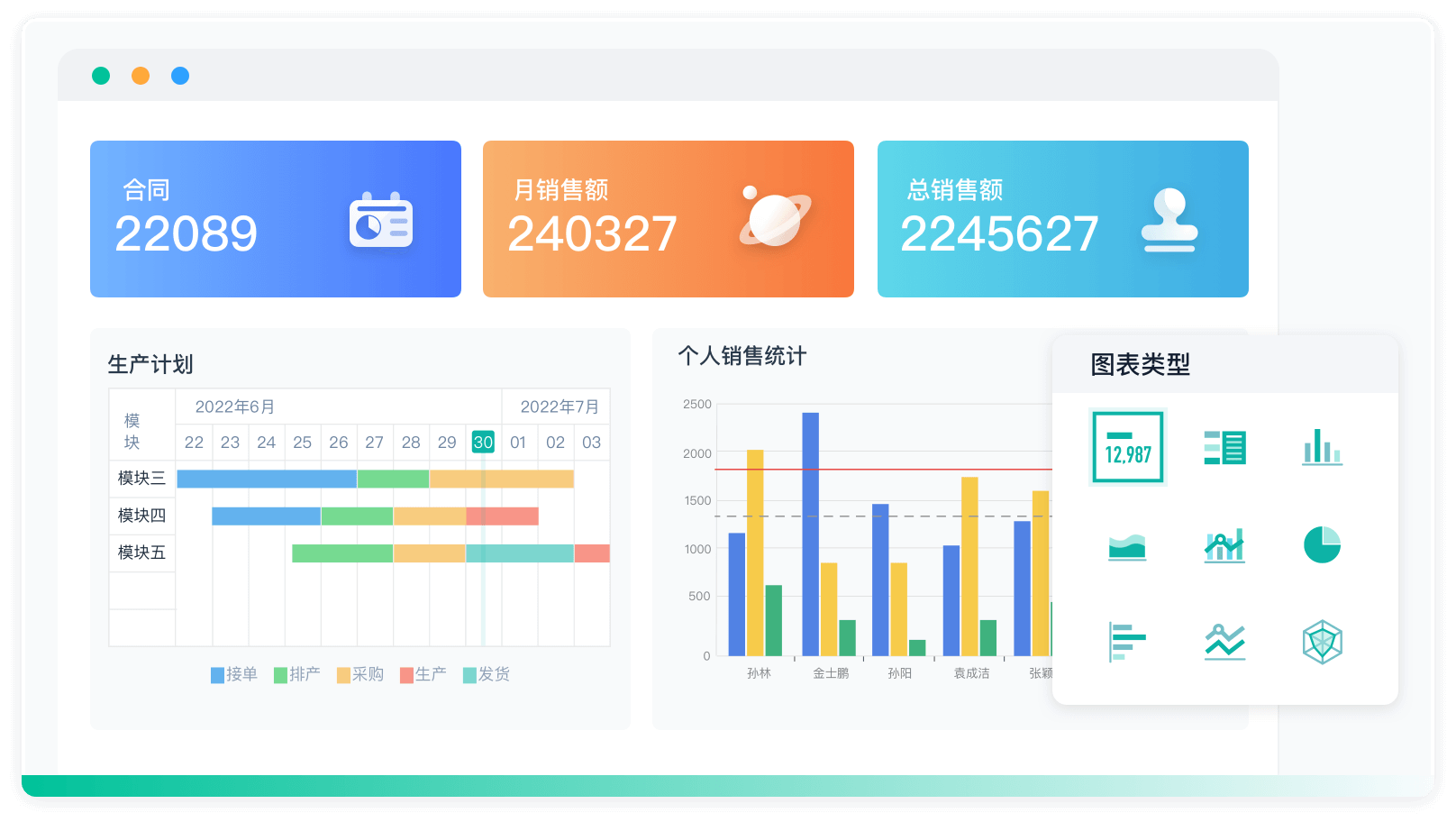

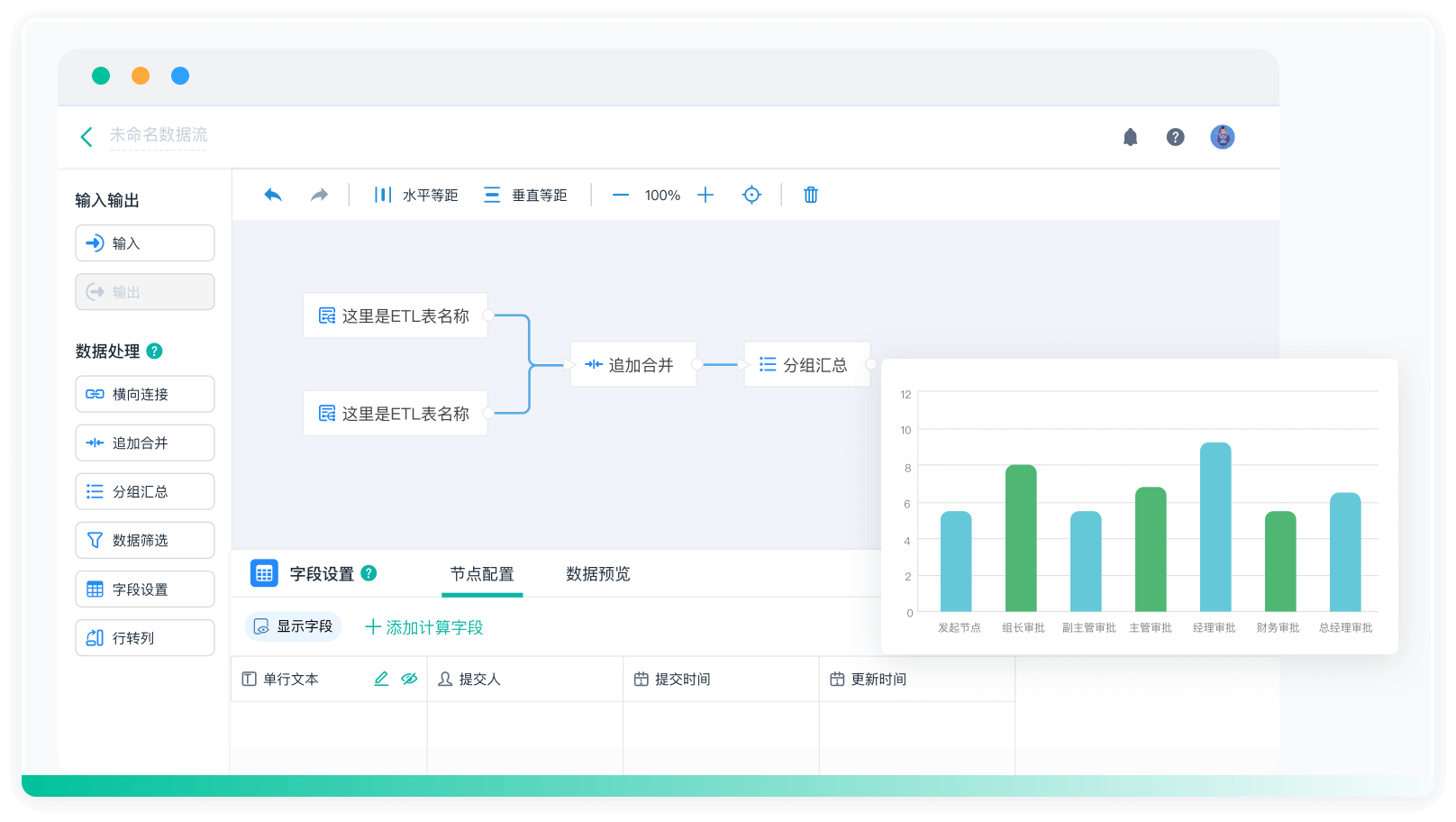

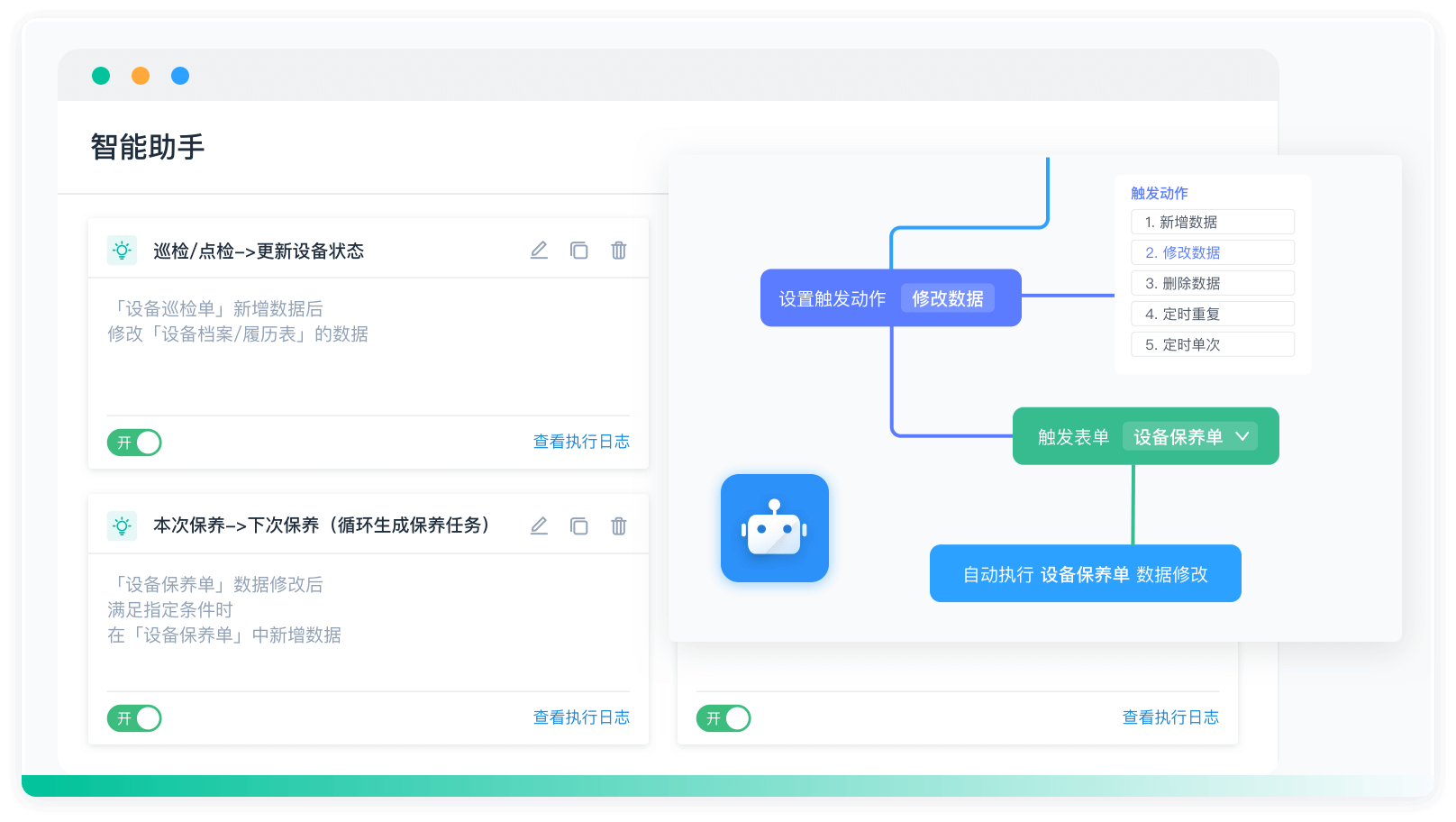

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

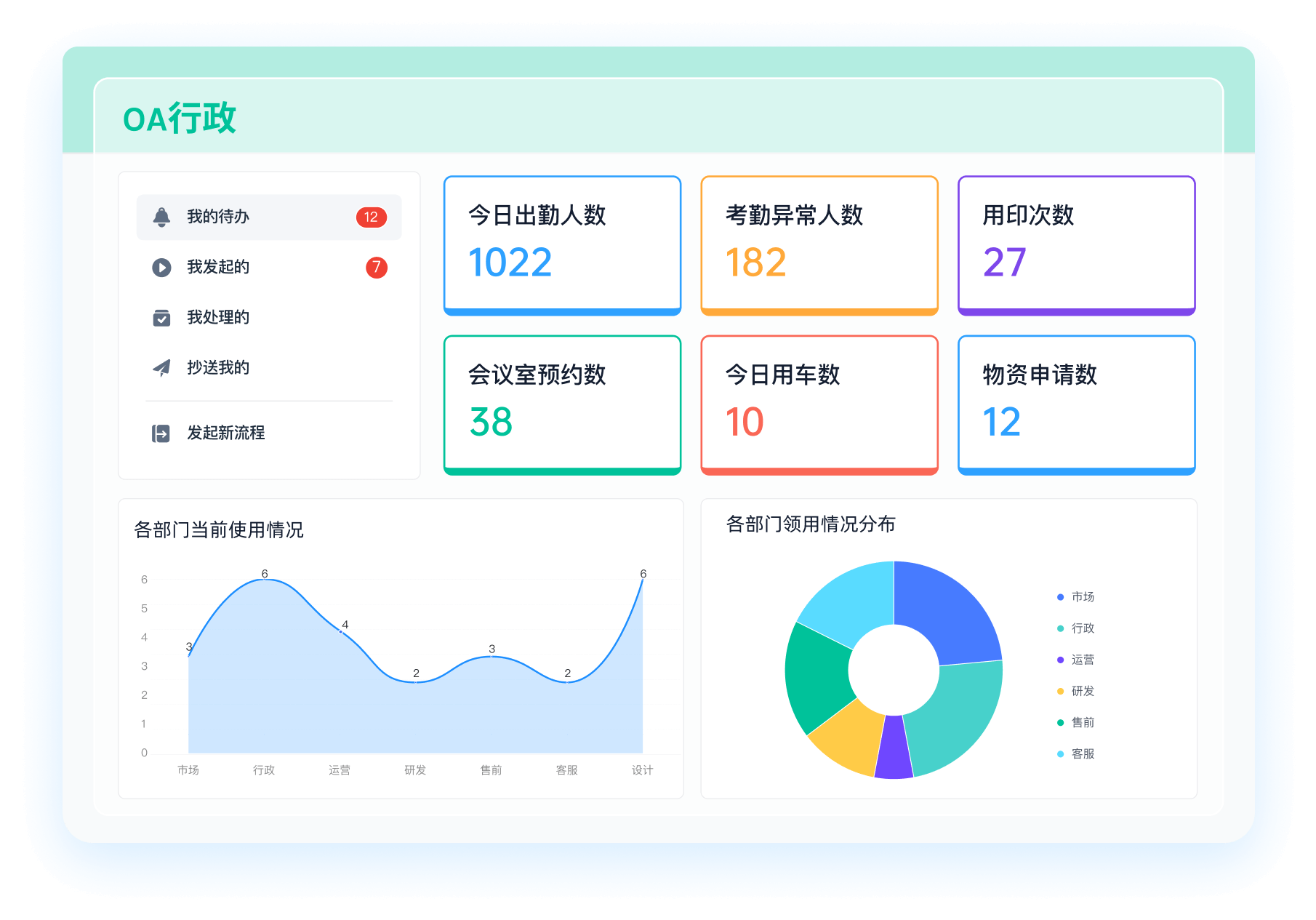

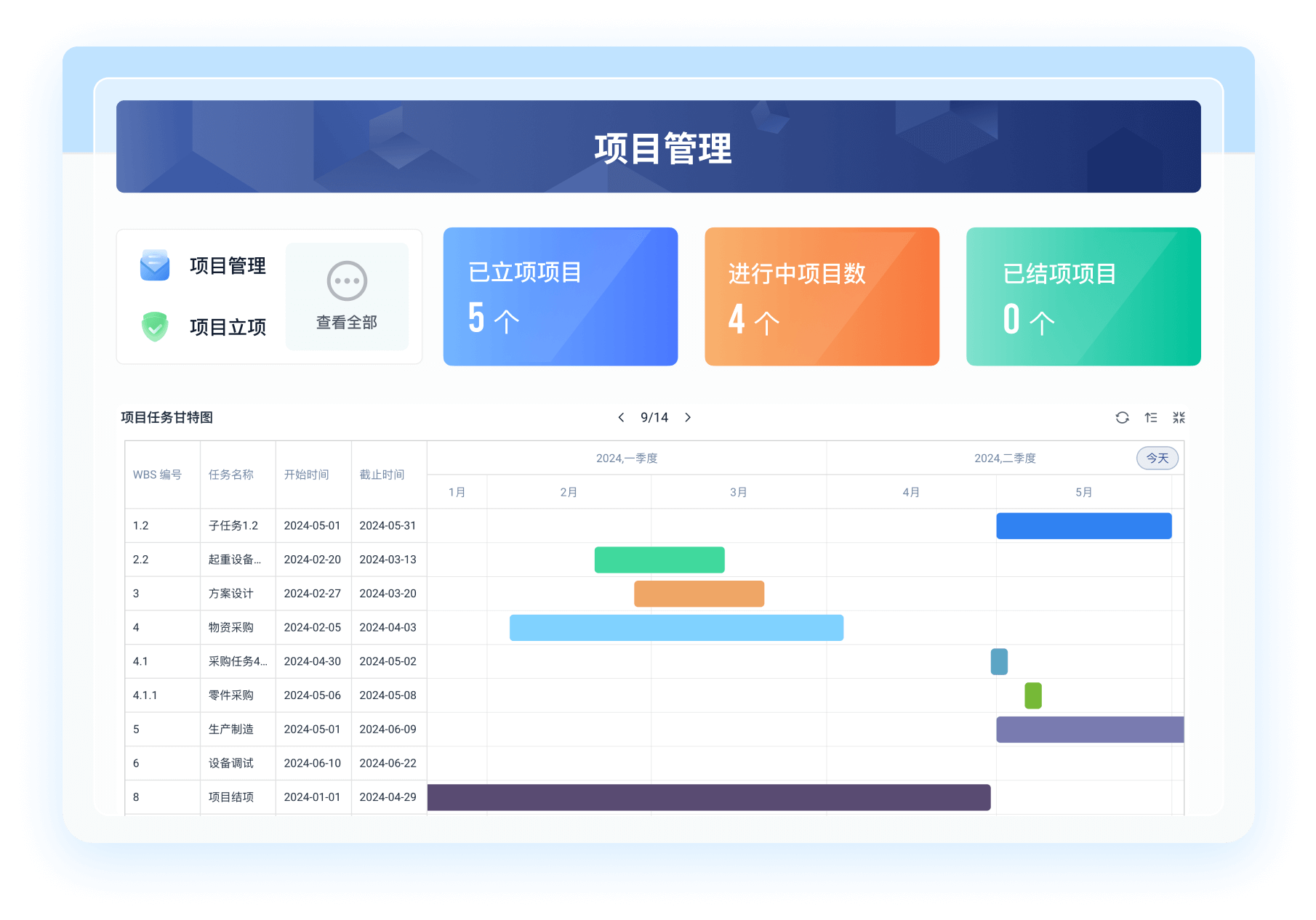

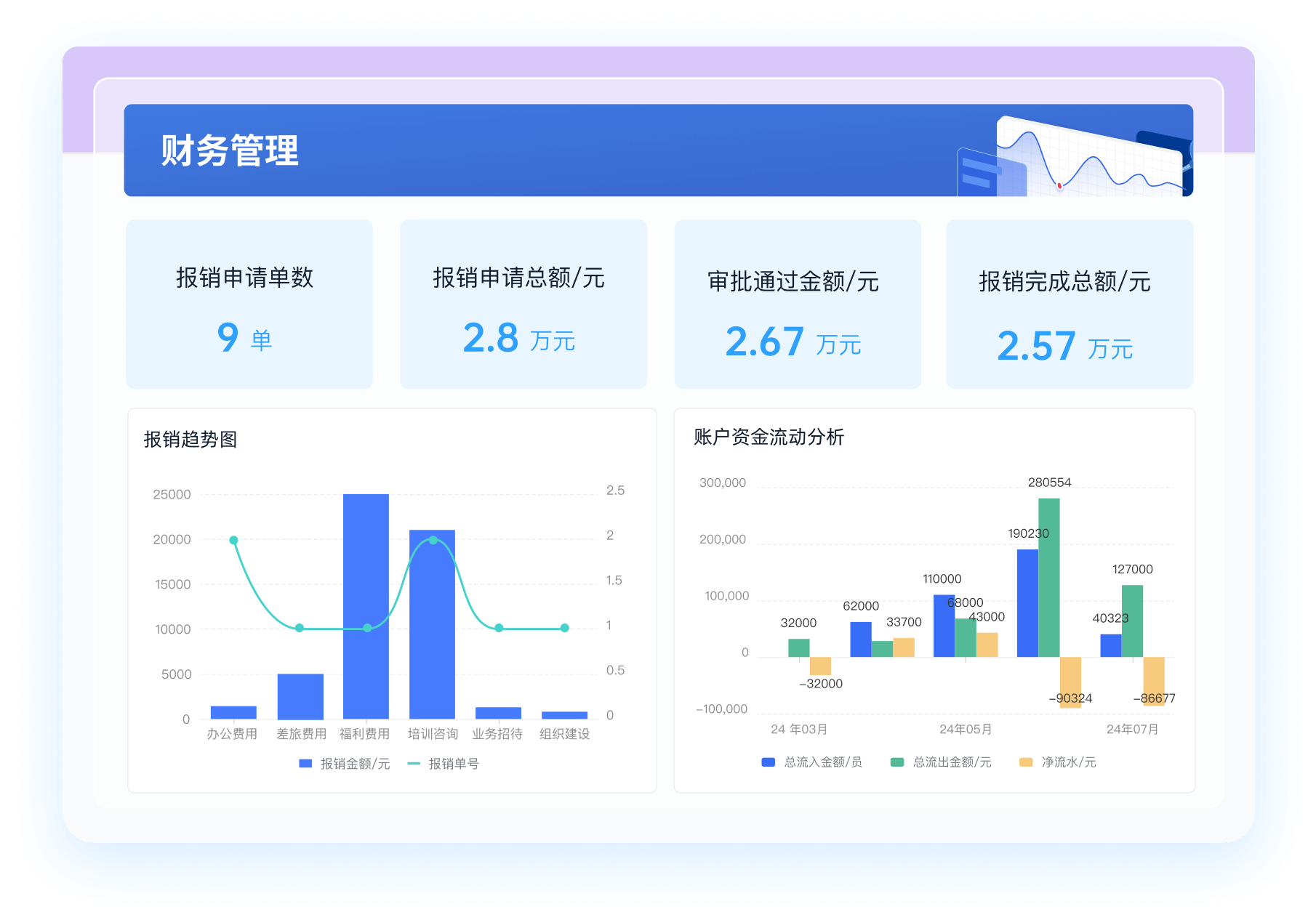

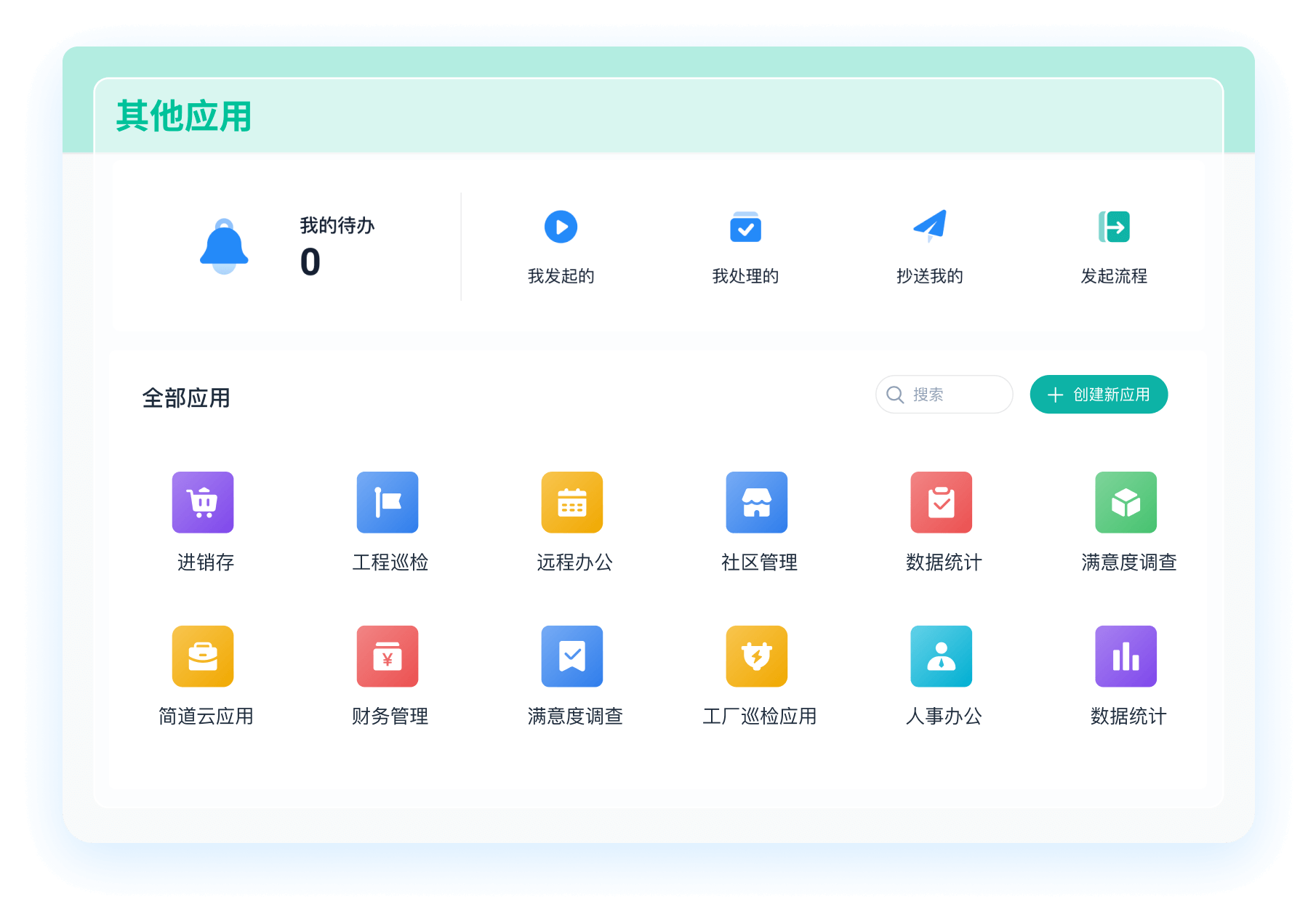

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理