该如何管理一个仓库呢英语

-

Managing a Warehouse: Best Practices and Strategies

I. Introduction

A warehouse plays a crucial role in the supply chain of a business by storing, organizing, and distributing goods efficiently. Managing a warehouse effectively involves a combination of proper planning, strategic decision-making, and efficient operations. In this guide, we will discuss the best practices and strategies for managing a warehouse successfully.II. Warehouse Management Methods

-

Inventory Management

a. Implement an inventory management system to track stock levels, reordering points, and item locations.

b. Conduct regular inventory audits to ensure accuracy in stock levels.

c. Utilize barcode scanning and RFID technology for faster and more accurate inventory tracking. -

Space Utilization

a. Optimize warehouse layout to maximize storage capacity and improve workflow.

b. Use vertical storage solutions like mezzanines and tall shelving to make the most of vertical space.

c. Categorize products based on demand to allocate prime storage locations accordingly. -

Order Fulfillment

a. Streamline order picking processes by organizing products logically and minimizing travel time.

b. Implement a pick-by-voice or pick-to-light system for faster and more accurate order picking.

c. Monitor order fulfillment metrics like order accuracy and turnaround time to identify areas for improvement. -

Shipping and Receiving

a. Establish efficient receiving processes to quickly unload, inspect, and store incoming shipments.

b. Use software systems to track incoming and outgoing shipments and generate shipping labels.

c. Implement a cross-docking strategy to reduce handling costs and improve order processing speed.

III. Warehouse Operation Procedures

-

Safety Protocols

a. Develop and enforce safety procedures to prevent accidents and injuries in the warehouse.

b. Provide proper training on equipment usage and safe handling of materials.

c. Conduct regular safety inspections and address any hazards promptly. -

Quality Control

a. Implement quality control checks to ensure that products meet set standards before shipping.

b. Assign dedicated staff to inspect products for damage, defects, or expiration dates.

c. Keep detailed records of quality control checks for future reference. -

Maintenance and Repairs

a. Schedule regular maintenance for warehouse equipment like forklifts, conveyors, and racking systems.

b. Promptly address any equipment malfunctions or breakdowns to prevent disruptions in operations.

c. Keep spare parts on hand for quick repairs and replacements. -

Staff Training and Development

a. Provide ongoing training for warehouse staff on operations, safety procedures, and new technologies.

b. Encourage employee engagement and feedback to identify areas for improvement.

c. Recognize and reward high-performing employees to boost morale and retention.

IV. Key Performance Indicators (KPIs)

-

Order Accuracy Rate

Measure the percentage of orders picked and shipped without errors to gauge operational efficiency. -

Inventory Turnover Ratio

Calculate how quickly inventory is moving out of the warehouse to optimize stock levels and reduce holding costs. -

On-Time Delivery

Track the percentage of orders delivered to customers on time to ensure customer satisfaction. -

Space Utilization Rate

Evaluate how effectively warehouse space is being used to identify opportunities for optimization.

V. Conclusion

Managing a warehouse effectively requires a combination of strategic planning, efficient operations, and continuous improvement. By implementing the best practices and strategies outlined in this guide, businesses can streamline warehouse operations, improve productivity, and enhance customer satisfaction. Remember, a well-managed warehouse is essential for a successful supply chain and overall business success.

1年前 -

-

Managing a warehouse effectively requires careful planning, organization, and supervision to ensure that operations run smoothly and efficiently. Here are five key steps to consider when managing a warehouse:

-

Develop a detailed layout plan: Start by creating a detailed layout plan for the warehouse that takes into account the size and shape of the space, as well as the types of products being stored. Ensure that there is enough room for inventory storage, aisles for forklifts and other equipment to move around, and designated areas for receiving, packing, and shipping goods. Organizing the layout in a logical and efficient manner will help streamline operations and minimize confusion.

-

Implement a robust inventory management system: Keeping track of inventory is crucial in a warehouse setting to prevent overstocking, stockouts, or misplaced items. Implement an inventory management system that uses barcoding, RFID technology, or a warehouse management software to track products from the moment they arrive at the warehouse to when they are shipped out. This system should enable real-time monitoring of inventory levels, provide accurate data on stock movements, and help optimize storage space.

-

Optimize picking and packing processes: Efficient picking and packing processes are essential for fulfilling customer orders quickly and accurately. Implement strategies such as batch picking, zone picking, or wave picking to streamline the order fulfillment process and reduce picking errors. Ensure that items are properly labeled, packaged securely, and organized in a way that makes it easy for workers to locate and pick them. Investing in automation technologies like conveyor systems or pick-to-light systems can further improve picking and packing efficiency.

-

Prioritize safety and security measures: Safety should be a top priority in any warehouse environment to prevent accidents, injuries, and damage to goods. Conduct regular safety training for warehouse staff on how to operate equipment safely, handle hazardous materials, and follow proper lifting techniques. Implement safety protocols such as wearing personal protective equipment (PPE), maintaining clear aisleways, and conducting regular equipment inspections. Additionally, install security measures like CCTV cameras, access control systems, and alarm systems to protect against theft, vandalism, and unauthorized access to the warehouse.

-

Continuously monitor and improve warehouse performance: Regularly monitor key performance indicators (KPIs) such as order accuracy, inventory turnover, picking productivity, and on-time delivery to assess the warehouse's performance. Use this data to identify areas for improvement and implement process enhancements, employee training, and technology upgrades to increase efficiency and productivity. Encourage a culture of continuous improvement among warehouse staff by seeking their feedback, implementing their suggestions, and recognizing and rewarding their contributions to the warehouse's success.

By following these key steps and implementing best practices in warehouse management, you can create a well-organized and efficient warehouse operation that meets the demands of your business and customers.

1年前 -

-

Warehouse management involves the efficient control and organization of all activities within a warehouse to ensure the smooth flow of goods and materials. Effective warehouse management is crucial for optimizing operations, minimizing costs, and meeting customer demand. Here are some key aspects to consider when managing a warehouse:

-

Optimizing Layout and Organization:

- Design the warehouse layout to facilitate the efficient flow of goods, minimizing the need for excessive handling or movement.

- Implement a logical system for organizing stock, such as ABC classification or bin locations, to optimize picking and stocking processes.

- Ensure that high-demand items are easily accessible to expedite order fulfillment.

-

Inventory Management:

- Implement an inventory tracking system to monitor stock levels, reordering points, and turnover rates.

- Conduct regular cycle counting and inventory audits to maintain accuracy.

- Utilize technology such as barcode scanning or RFID systems to streamline inventory management processes.

-

Receiving and Dispatch:

- Establish standard operating procedures for receiving goods, including inspection, labeling, and storage protocols.

- Prioritize incoming shipments based on urgency and storage availability.

- Develop efficient picking and packing processes for order fulfillment, considering factors like order batching and picking routes.

-

Warehouse Safety and Security:

- Implement safety protocols and provide training for warehouse staff to prevent accidents and injuries.

- Maintain a clean and organized work environment to mitigate safety hazards.

- Install security measures such as surveillance cameras and access control systems to safeguard inventory and assets.

-

Technology Integration:

- Utilize warehouse management software to automate processes, track inventory in real-time, and generate reports for analysis.

- Explore other technologies like automated guided vehicles (AGVs) or warehouse robots to enhance efficiency in tasks like picking, packing, and transportation.

-

Supplier and Customer Relations:

- Establish good communication channels with suppliers to ensure timely deliveries and resolve any issues promptly.

- Collaborate with customers to understand their requirements and provide excellent service in terms of order accuracy and on-time delivery.

-

Performance Metrics and Continuous Improvement:

- Define key performance indicators (KPIs) to measure warehouse performance, such as order fulfillment rate, inventory accuracy, and turnaround time.

- Regularly analyze data and KPIs to identify areas for improvement and implement strategies to enhance warehouse efficiency.

In conclusion, effective warehouse management involves a combination of strategic planning, efficient processes, technology utilization, and continuous improvement efforts. By implementing best practices in layout optimization, inventory management, safety measures, technology integration, and customer relations, a warehouse can operate smoothly, meet demand efficiently, and drive overall business success.

1年前 -

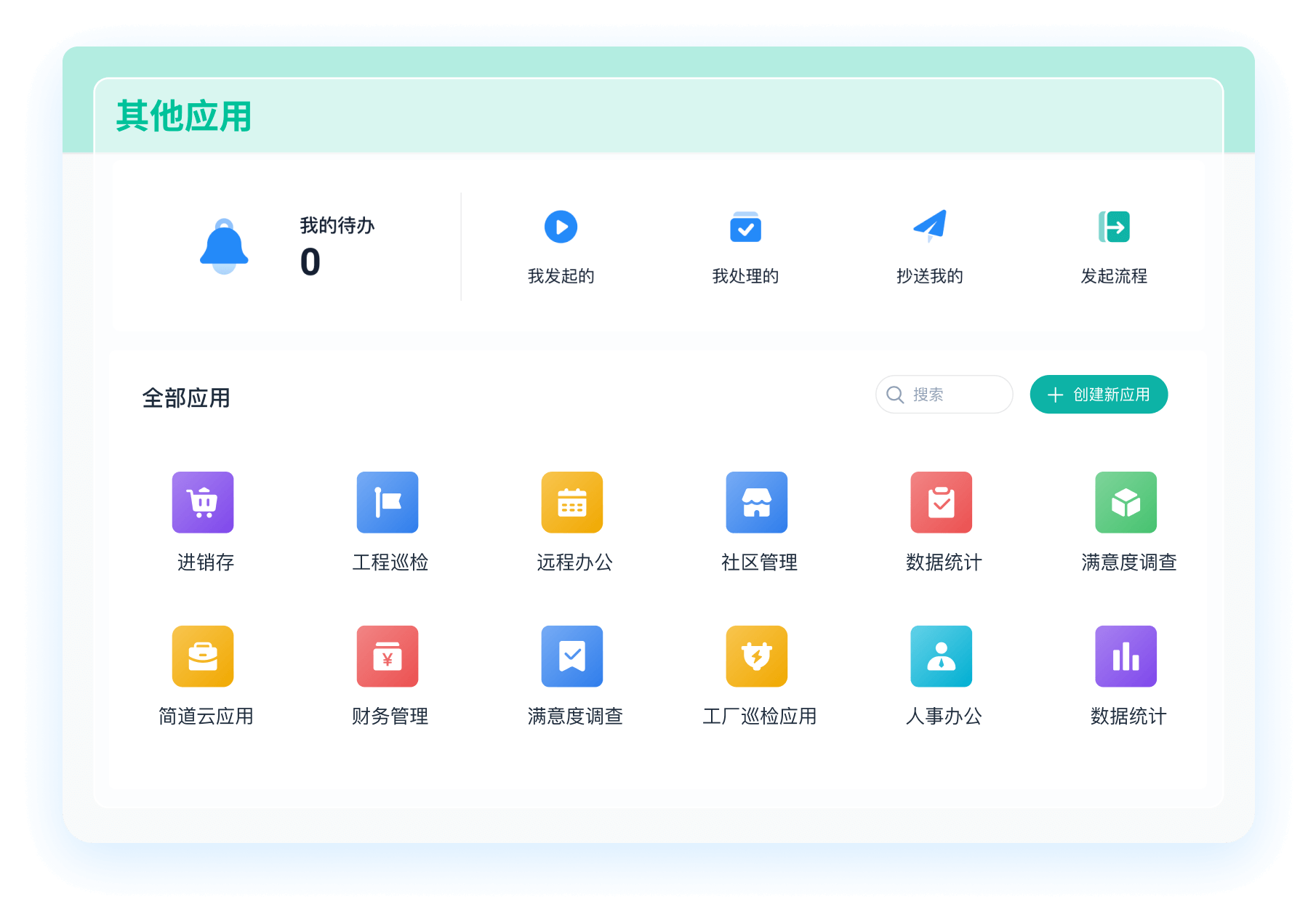

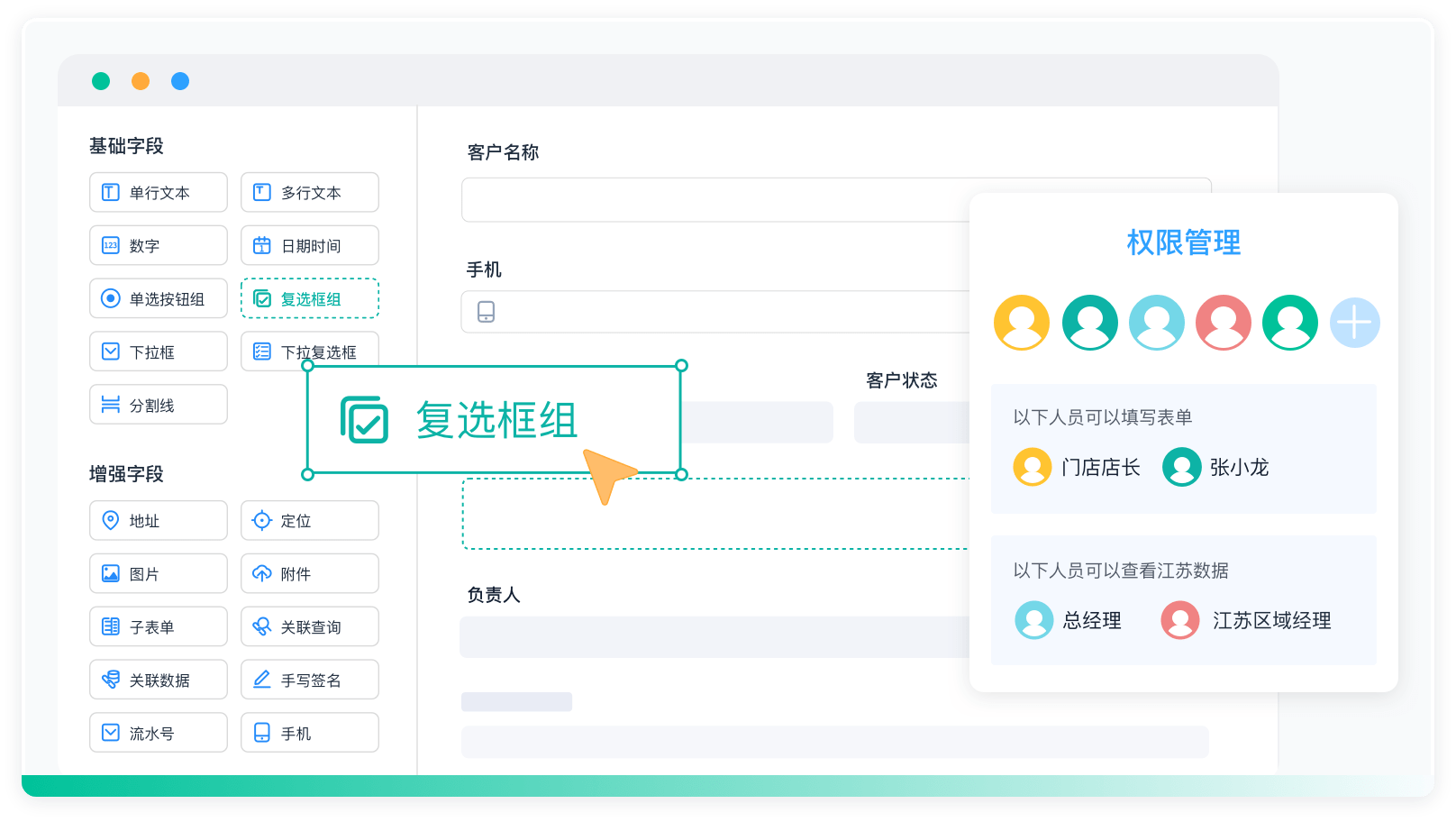

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理