仓库管理员如何控制成本

-

Title: How Warehouse Managers Can Control Costs

Introduction: In a warehouse setting, controlling costs is essential for maintaining profitability and efficiency. Warehouse managers must utilize a variety of strategies and techniques to help minimize expenses and maximize revenue. This article will discuss methods, operational procedures, and best practices that warehouse managers can implement to effectively control costs.

1. Utilize Inventory Management Systems

- Implementing an inventory management system is crucial for controlling costs in a warehouse. These systems help track inventory levels, monitor stock movement, and prevent overstocking or stockouts.

- Use automated systems for inventory tracking and management to reduce errors and improve overall efficiency.

- Utilize real-time data to make informed decisions about inventory levels, reorder points, and stocking locations.

2. Optimize Warehouse Layout and Organization

- Design the warehouse layout in a way that minimizes travel time for workers and streamlines the picking and packing process.

- Use efficient storage methods such as bulk storage, bin locations, and vertical storage to maximize space utilization.

- Regularly review and optimize the warehouse layout to adapt to changing inventory needs and volume.

3. Implement Lean Principles

- Adopt lean principles such as just-in-time inventory management, waste reduction, and continuous improvement to streamline operations and minimize costs.

- Encourage employee involvement in identifying and eliminating waste within warehouse processes.

- Implement visual management techniques to make processes more transparent and easier to monitor.

4. Control Labor Costs

- Analyze labor efficiency and productivity to identify areas for improvement and cost-saving opportunities.

- Cross-train employees to enhance flexibility and minimize the need for additional labor during peak periods.

- Implement performance metrics and incentives to motivate employees and improve overall productivity.

5. Opt for Energy-Efficient Practices

- Implement energy-efficient lighting and heating systems to reduce electricity and heating costs.

- Monitor and optimize energy usage throughout the warehouse, including equipment operation and ventilation systems.

- Consider investing in renewable energy sources such as solar panels to further reduce energy costs in the long term.

6. Utilize Data Analytics

- Use data analytics tools to analyze trends, identify cost-saving opportunities, and make data-driven decisions.

- Monitor key performance indicators (KPIs) such as inventory turnover, order accuracy, and labor productivity to assess warehouse performance.

- Leverage predictive analytics to anticipate demand fluctuations and adjust inventory levels accordingly.

7. Collaborate with Suppliers

- Build strong relationships with suppliers to negotiate favorable terms, discounts, and bulk pricing.

- Collaborate with suppliers to implement vendor-managed inventory (VMI) or consignment inventory to reduce inventory carrying costs.

- Regularly review supplier performance and seek opportunities for cost savings through improved collaboration.

Conclusion

Controlling costs in a warehouse environment requires a strategic approach that considers various factors such as inventory management, labor efficiency, energy usage, and supplier relationships. By implementing the methods and best practices outlined above, warehouse managers can effectively control costs, improve operational efficiency, and maintain profitability.

1年前 -

仓库管理员在控制成本方面可以采取多种策略和措施,以下是一些可以帮助仓库管理员有效控制成本的方法:

-

合理管理库存水平:仓库管理员需要根据市场需求、销售趋势和供应链的情况,合理制定库存水平。避免库存积压或库存不足,以免造成资金被长时间占用或销售订单无法及时处理的情况。

-

优化供应链管理:仓库管理员可以通过加强与供应商的沟通与协调,优化供应链运作,降低采购成本。建立稳定的供应关系,采取批量采购或提前采购等方式,享受更优惠的价格。

-

提高仓库利用率:合理规划仓库布局、优化仓储空间利用率,避免出现因堆放不当或浪费空间而导致的成本增加。适时清理过期、滞销或损坏的货物,减少库存积压。

-

优化物流运作:通过提高物流效率,减少仓库货物的装卸、存储和搬运时间,降低人力成本和能源消耗。合理安排出货计划和优化配送路线,降低运输成本。

-

实施精细化管理:建立完善的仓储管理制度和流程,采用信息化技术和物联网技术,实现对库存、入库、出库等各个环节的实时监控和管理。及时发现问题并进行调整,避免出现潜在的成本损失。

-

降低损耗率:加强对货物的保管和维护,建立完善的防火、防潮、防盗措施,降低货物损坏和丢失率。合理包装货物,减少在搬运、运输过程中的破损率。

-

控制人力成本:根据实际需求和工作量合理安排仓库员工的工作时间和人数,避免因过度用工或用工不足而导致的成本增加。定期进行培训和考核,提升员工工作效率。

综上所述,仓库管理员可以通过合理管理库存水平、优化供应链管理、提高仓库利用率、优化物流运作、实施精细化管理、降低损耗率以及控制人力成本等手段,有效控制仓库管理成本,提高企业的经济效益和竞争力。

1年前 -

-

仓库管理员在控制成本方面有很多方法和策略,以下是一些有效的措施:

-

合理规划仓库布局:仓库管理员可以通过合理规划仓库布局来最大程度地利用仓库空间,避免空间浪费。合理的仓库布局可以提高仓库的存储能力,减少货物损耗和损坏,进而减少仓库管理成本。

-

优化库存管理:仓库管理员应该合理控制库存水平,避免过多的库存积压和滞销问题。通过制定科学合理的库存管理策略,如采用先进的库存管理系统,实行精细化库存管理等措施,可以降低库存成本,提高资金周转率。

-

提高工作效率:仓库管理员可以通过提高工作效率来降低成本。采用现代化的仓库管理技术、自动化设备和信息化系统可以提高仓库作业效率,减少人力成本,提高工作效率。

-

降低运输成本:仓库管理员可以通过优化配送路线、选择合适的物流服务提供商、加强与供应商的合作等方式来降低运输成本。合理安排运输计划,提高货运效率,减少运输中的损失和延误,可以有效降低运输成本。

-

精细化成本控制:仓库管理员可以通过精细化的成本控制来降低仓库管理成本。对于各项费用进行分类管理,定期进行成本核算和分析,找出成本高昂的环节,采取相应的措施降低成本,从而提高仓库经营效益。

1年前 -

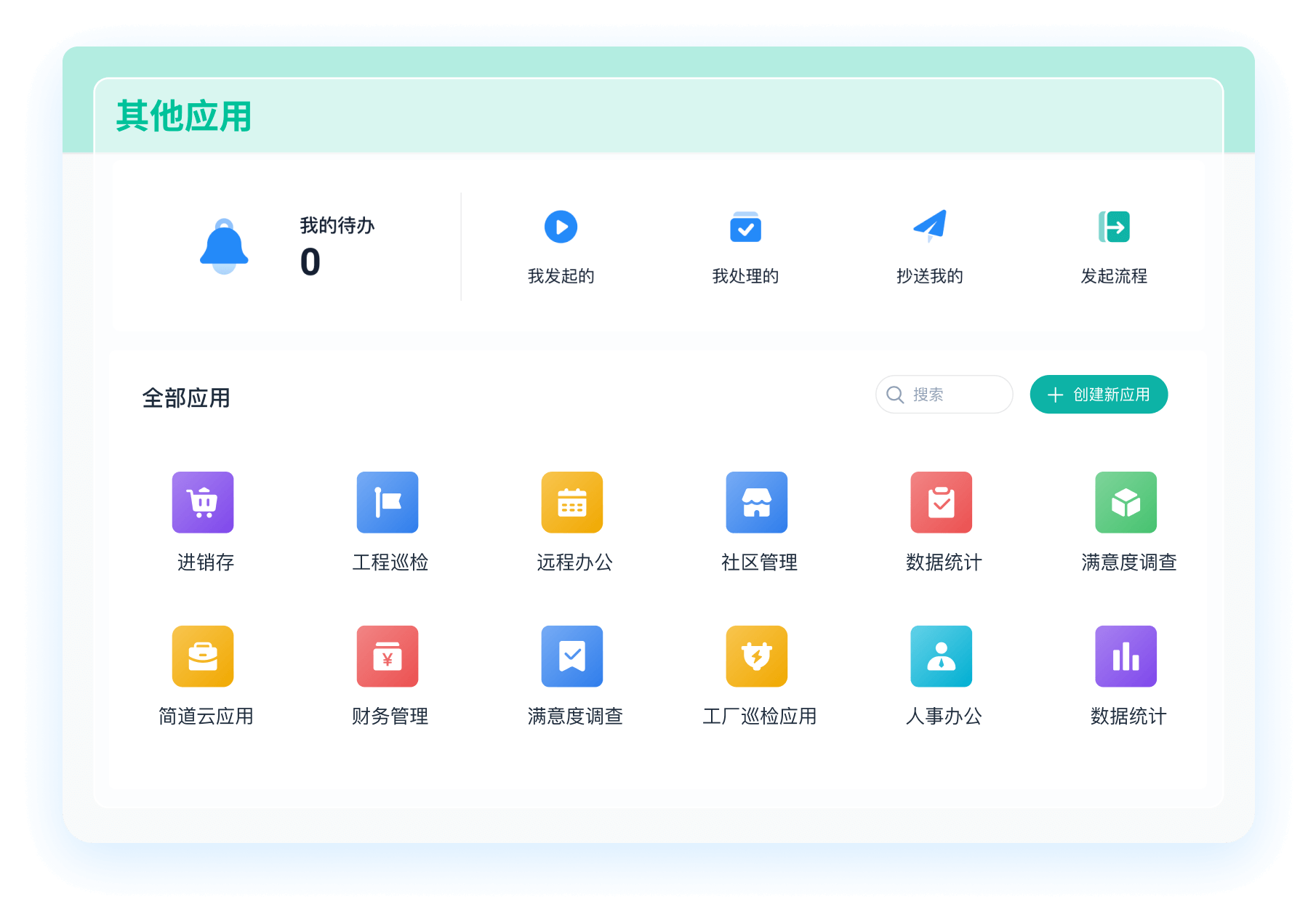

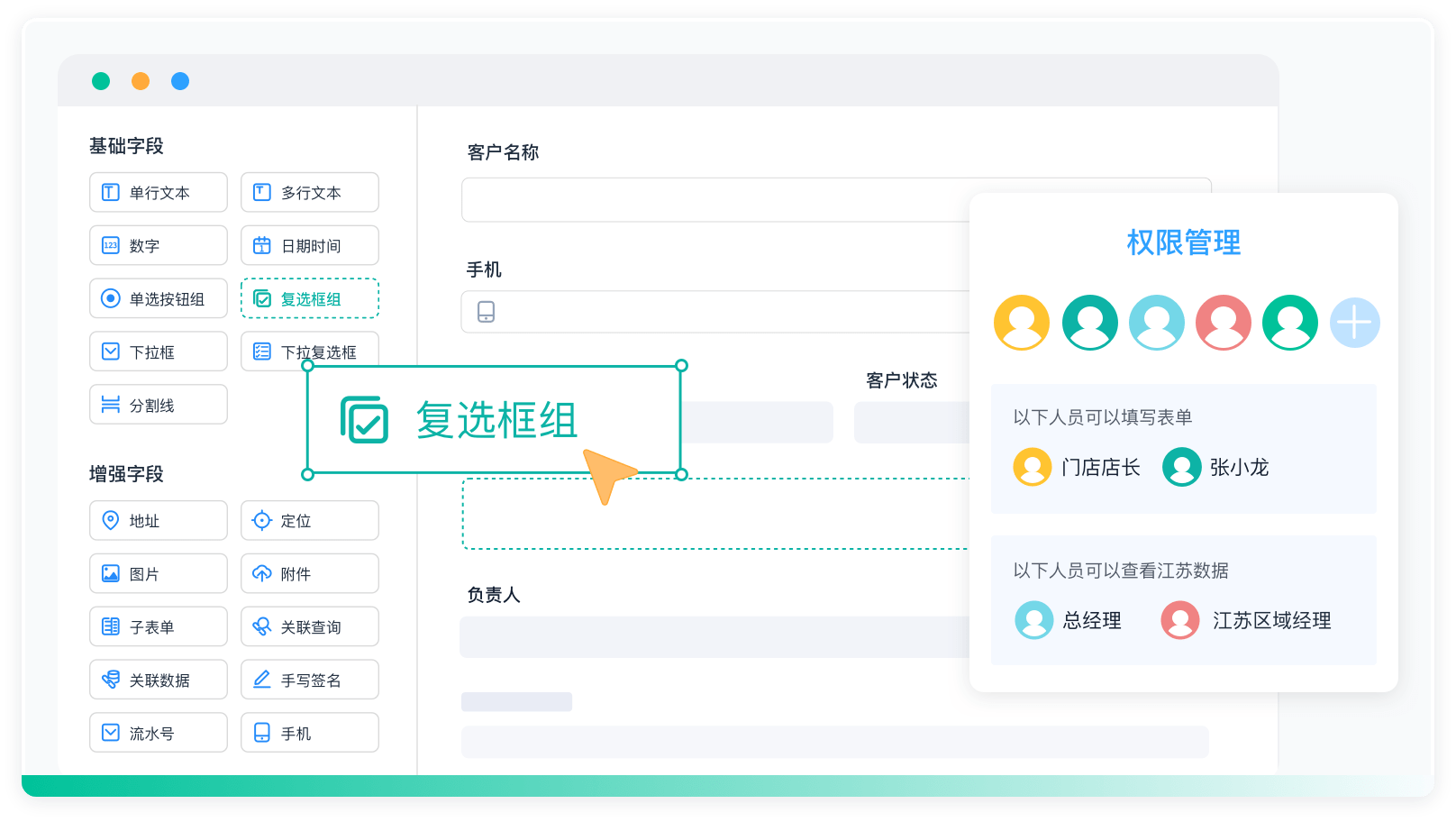

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理