仓库管理口诀有哪些英文

-

仓库管理是管理企业重要资产的重要部分,而口诀可以帮助我们记住关键原则和步骤。以下是一些关于仓库管理的口诀的英文版本:

-

ABC 分类法:ABC Classification Method

- A 类物品:高价值低销量物品;Class A Items: High value, low quantity items

- B 类物品:中等价值中等销量物品;Class B Items: Medium value, medium quantity items

- C 类物品:低价值高销量物品。Class C Items: Low value, high quantity items

-

FIFO 原则:First-In-First-Out Principle

- 按照先进先出的原则管理货物,确保库存不过期;Manage inventory based on the principle of first items received are the first items sold to prevent expiration.

-

5S 方法:5S Methodology

- Sort(整理)、Set in order(整顿)、Shine(清扫)、Standardize(标准化)、Sustain(持续改进);Sort, Set in order, Shine, Standardize, Sustain

-

JIT 管理:Just-In-Time Management

- 精确计算库存,实现即时交付;Accurately calculate inventory to achieve on-time delivery

-

按需生产:On-Demand Production

- 根据需求灵活调整库存,避免过多库存占用资金;Flexible inventory adjustments based on demand to avoid tying up excessive capital in inventory

-

库存周转率:Inventory Turnover Rate

- 库存周转率 = 销售成本 / 平均库存数量;Inventory Turnover Rate = Cost of Goods Sold / Average Inventory Quantity

-

库存订购点:Reorder Point

- 订购点 = 日平均需求量 × 采购周期 + 安全库存;Reorder point = Daily Average Demand x Lead Time + Safety Stock

以上是一些关于仓库管理的口诀的英文版本,希望对您有所帮助。

1年前 -

-

-

ABC analysis method

ABC analysis method is to classify inventory items into three categories based on their importance and value: A items are the most important and account for the majority of inventory value, B items are of medium importance, and C items are the least important. -

FIFO (First In, First Out)

FIFO is a method of inventory management in which the first items purchased or produced are the first ones to be used or sold. This method helps ensure that older inventory is used first, reducing the risk of obsolescence or spoilage. -

LIFO (Last In, First Out)

LIFO is a method of inventory management in which the last items purchased or produced are the first ones to be used or sold. This can be particularly useful in times of rising costs, as it allows a company to reduce its taxable income by using the most recently acquired inventory (which is usually more expensive) first. -

JIT (Just In Time)

JIT is a method of inventory management in which inventory is ordered and received just in time to meet production needs. This helps reduce excess inventory, storage costs, and the risk of obsolescence, while also improving cash flow and efficiency. -

RFID (Radio Frequency Identification)

RFID technology uses electromagnetic fields to automatically identify and track inventory items. By using RFID tags and readers, companies can improve inventory accuracy, reduce manual labor, and streamline the tracking of inventory movements. -

WMS (Warehouse Management System)

A WMS is a software application that helps businesses manage and optimize warehouse operations. It includes features such as inventory tracking, order fulfillment, slotting optimization, and labor management, all aimed at improving warehouse efficiency and accuracy. -

Reorder Point

The reorder point is the inventory level at which a new order should be placed to replenish stock before it runs out. Calculating the reorder point involves considering factors such as lead time, demand variability, and safety stock levels. -

EOQ (Economic Order Quantity)

EOQ is a formula used to determine the optimal order quantity that minimizes total inventory costs. By balancing ordering costs and holding costs, companies can find the most cost-effective quantity to order each time. -

Cycle Counting

Cycle counting is a method of regularly counting a portion of inventory items on a rotating schedule, rather than doing a complete physical inventory count all at once. This helps maintain inventory accuracy, identify discrepancies, and reduce the need for large-scale inventory counts. -

Pick and Pack

Pick and pack is the process of selecting items from inventory (picking) and then packaging them for shipment (packing). This process is often automated with the help of technology such as barcode scanners and conveyor systems to improve accuracy and efficiency in order fulfillment.

1年前 -

-

There are several key principles and guidelines for warehouse management that are commonly used in English. Here are five key warehouse management principles in English:

-

ABC Analysis: This principle categorizes inventory into three groups – A, B, and C – based on their importance. A items are the most critical and usually represent a small portion of the inventory but a large portion of the value. B items are moderately important, while C items are lower in value and importance.

-

FIFO (First-In, First-Out): FIFO is a method of inventory management where the oldest stock is used or sold first. This helps prevent stock from becoming obsolete or expired and ensures that the inventory is rotated efficiently.

-

Safety First: Safety is a top priority in warehouse management to ensure the well-being of employees and the protection of goods. This includes following proper protocols for handling equipment, storing hazardous materials safely, and providing appropriate training for staff.

-

Lean Principles: Lean management focuses on optimizing processes to eliminate waste and improve efficiency. This includes keeping inventory levels low, streamlining workflows, and continuously improving operations.

-

Cycle Counting: Instead of traditional physical inventory counts, cycle counting involves counting a small portion of the inventory on a regular basis. This helps identify and correct discrepancies more quickly, leading to more accurate inventory records.

These are just a few key principles and guidelines for effective warehouse management in English. By following these principles and implementing best practices, warehouse managers can improve efficiency, reduce costs, and ensure the smooth operation of their facilities.

1年前 -

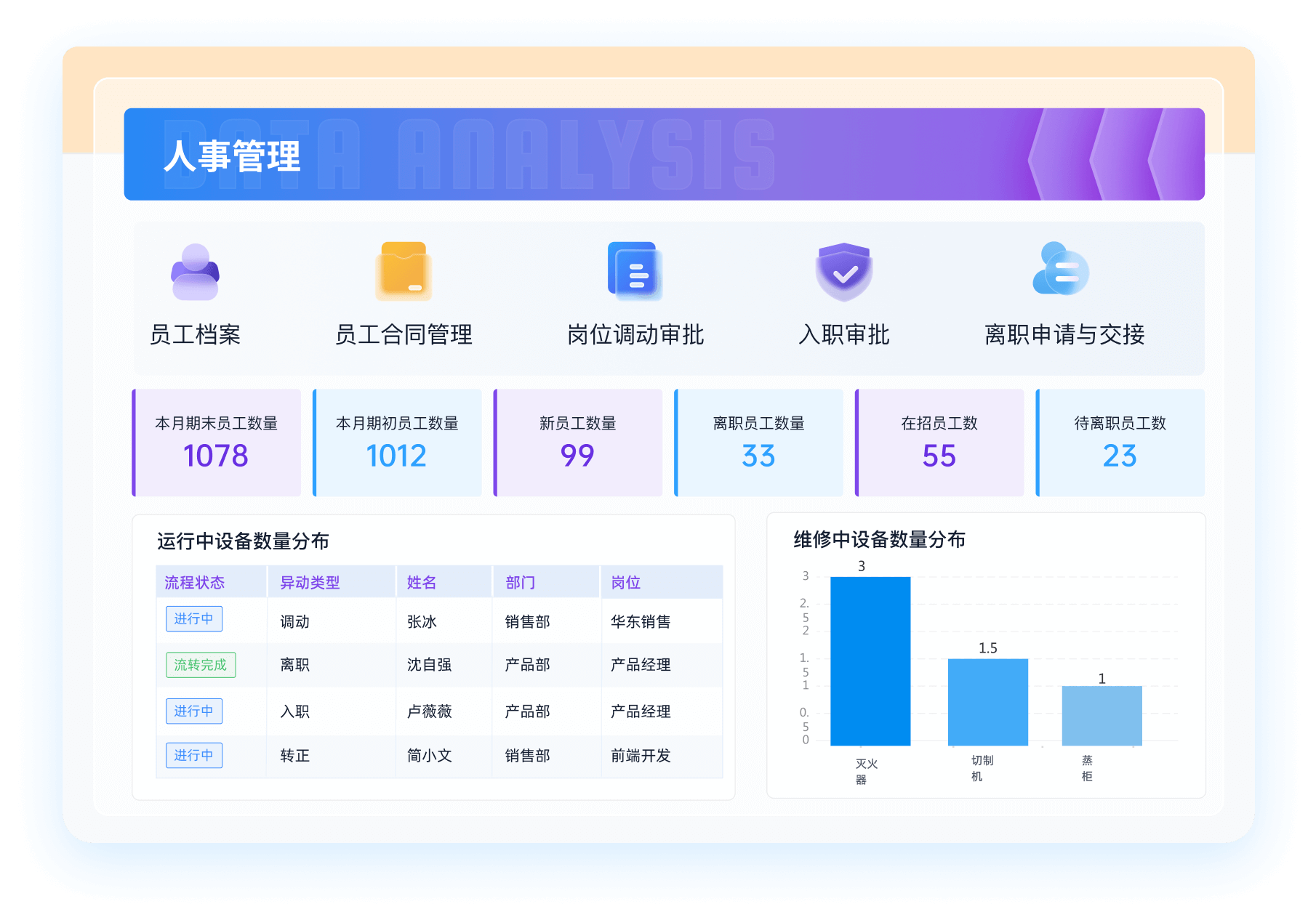

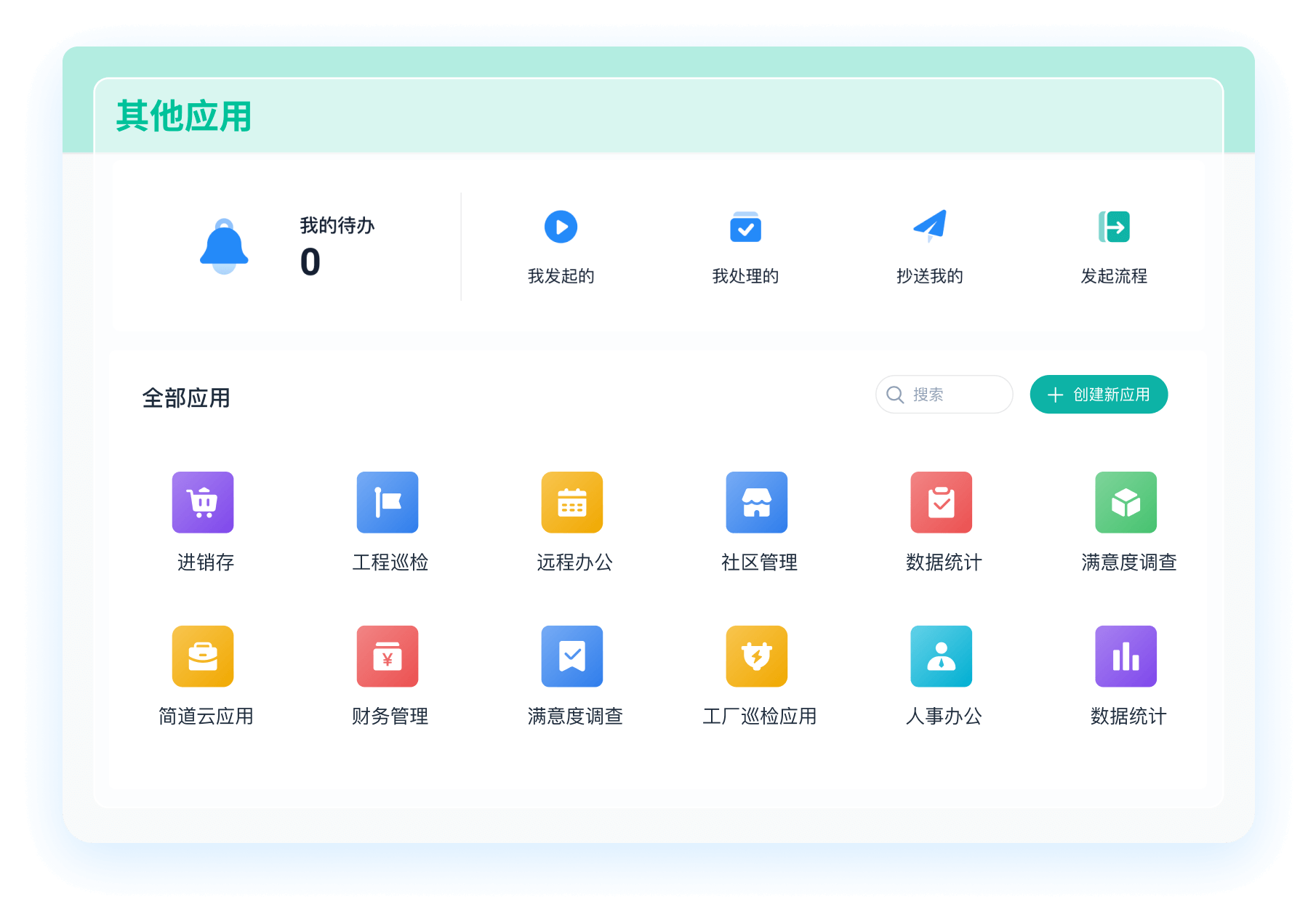

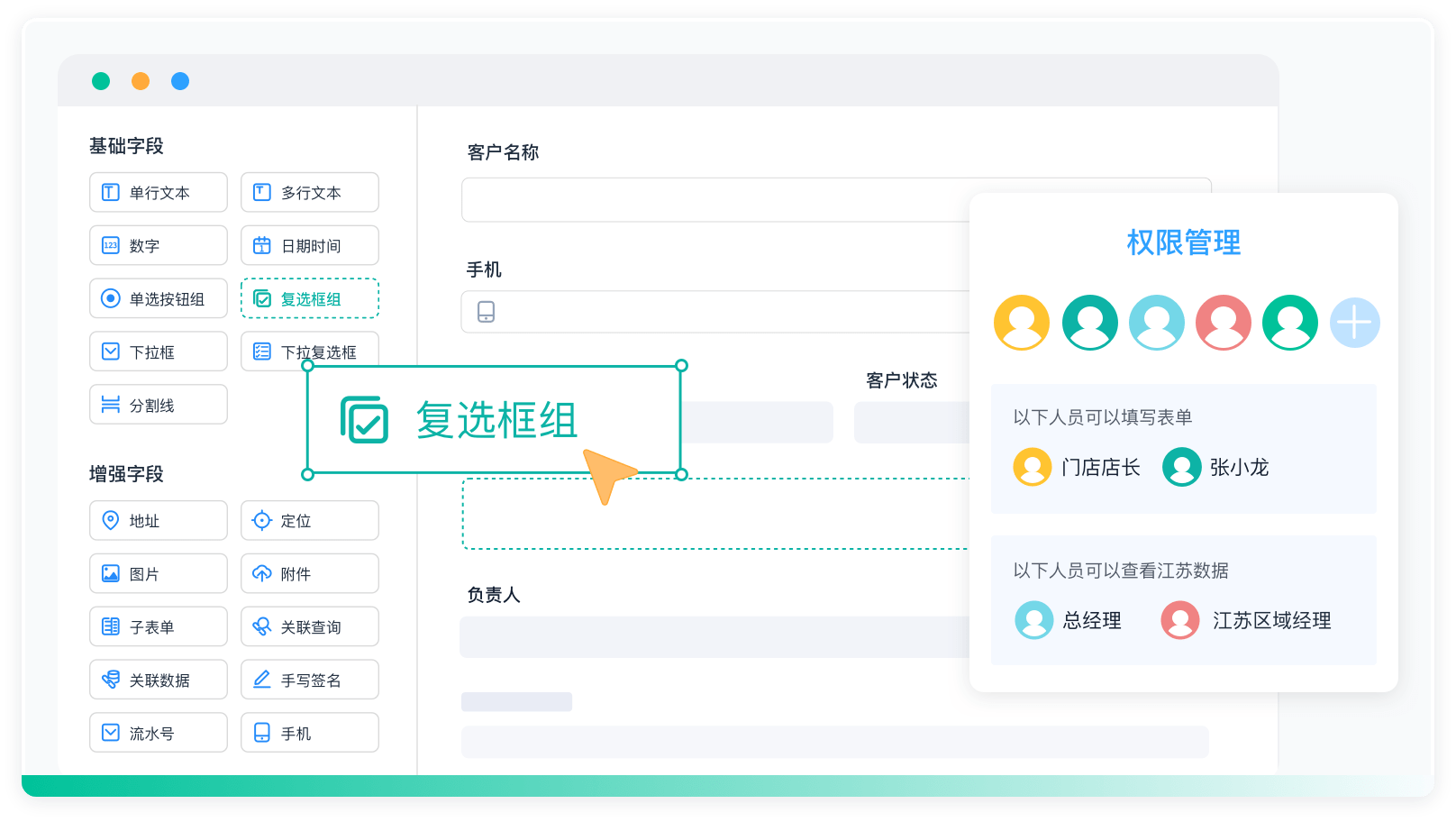

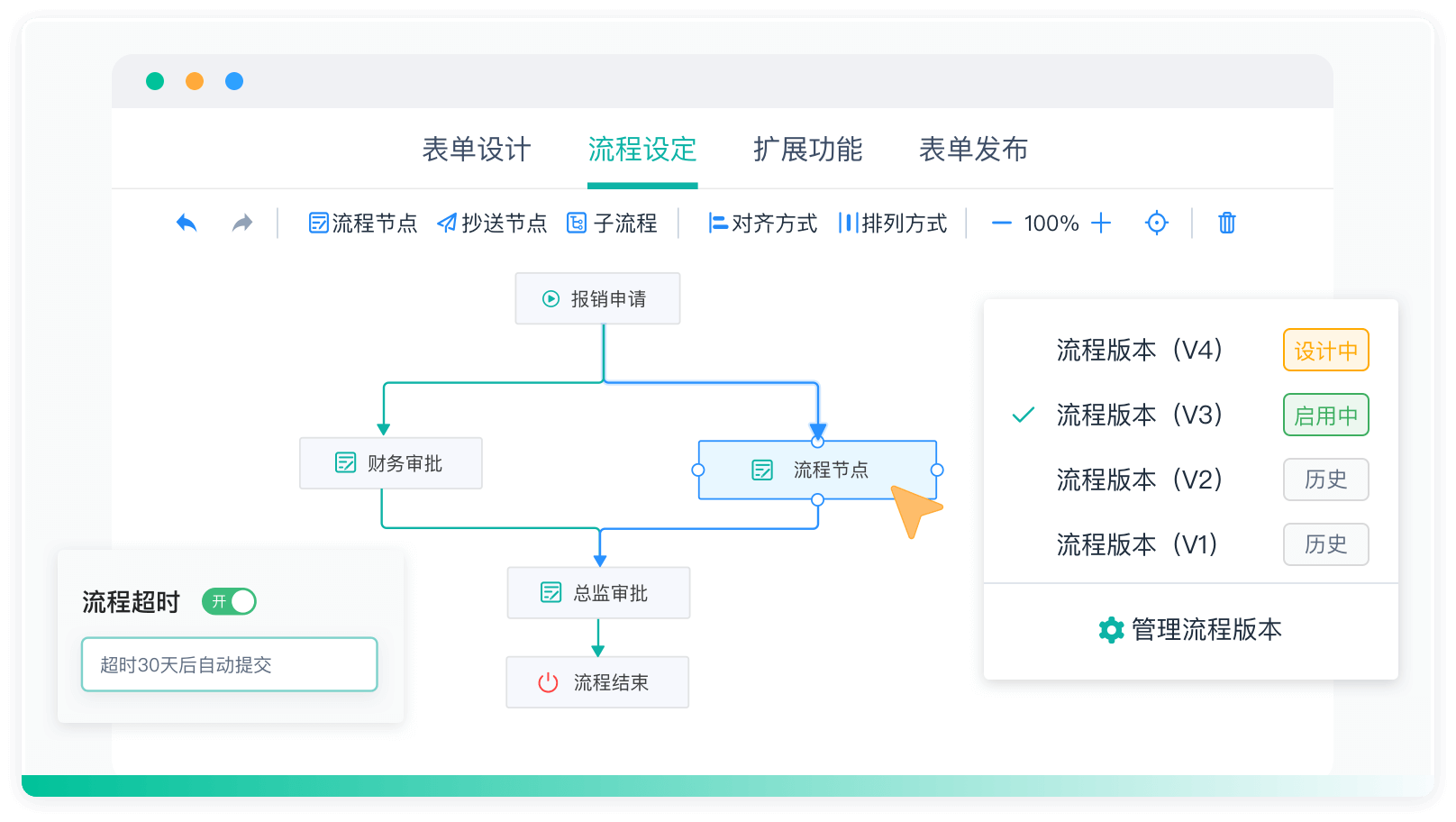

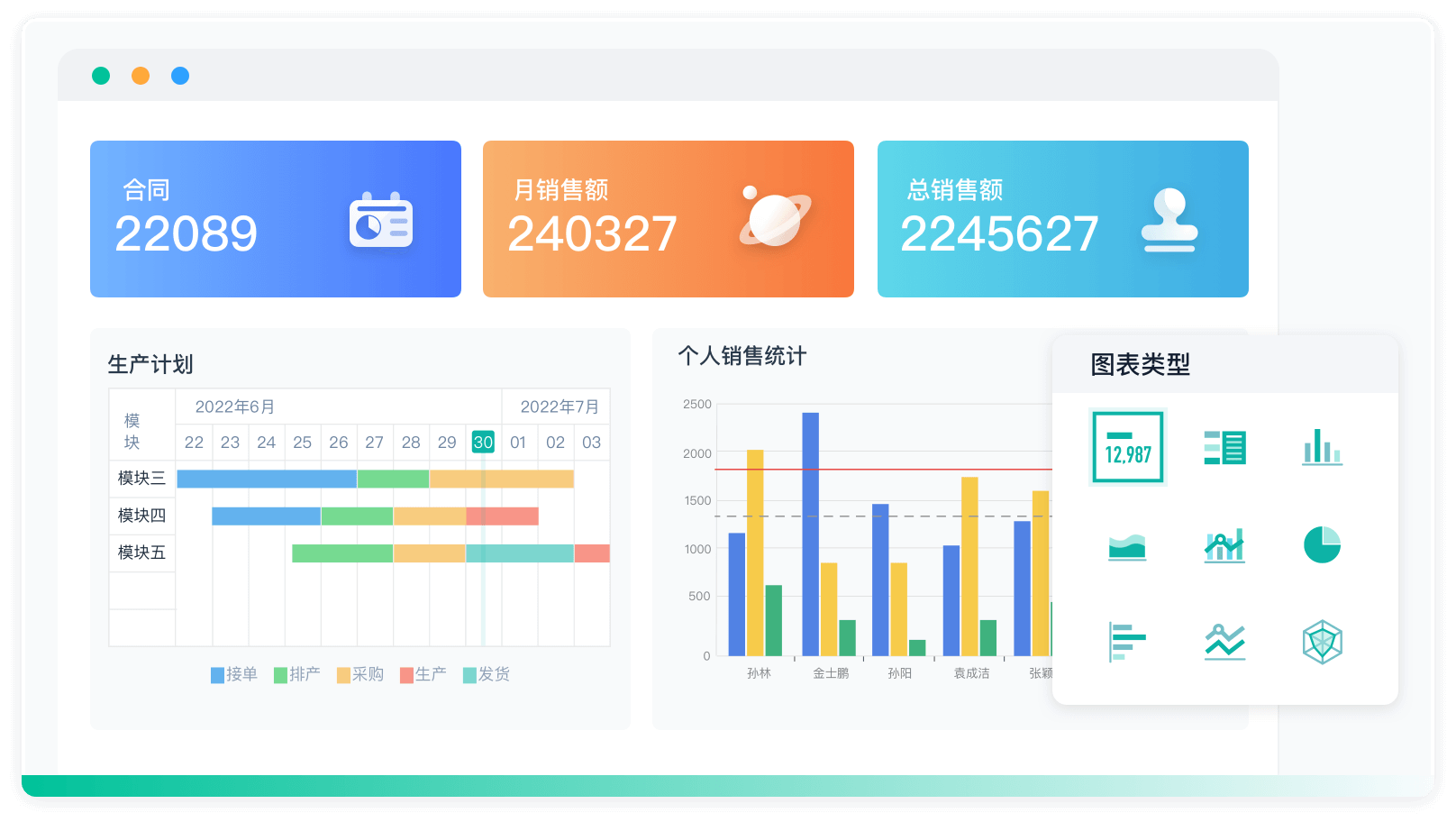

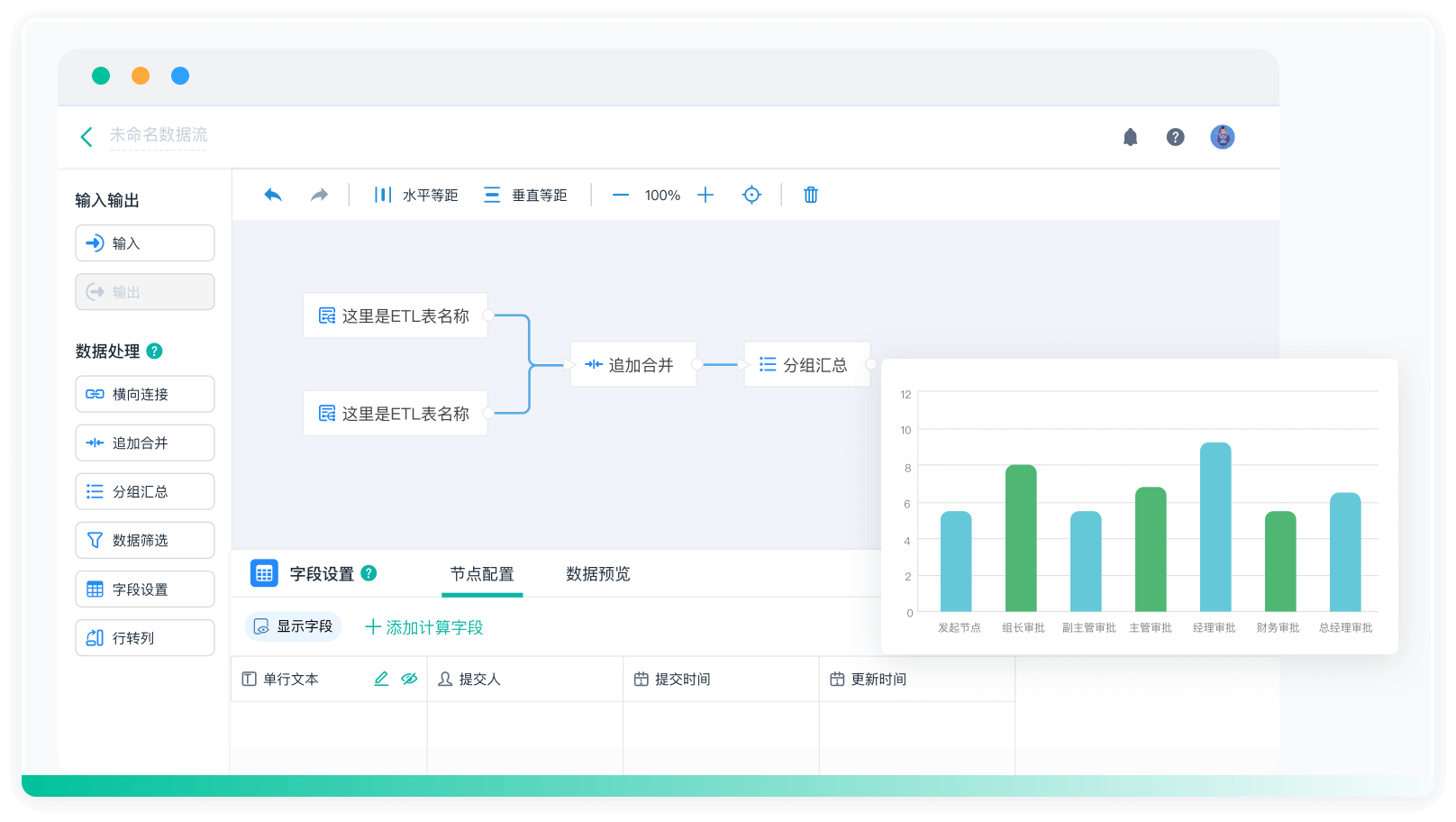

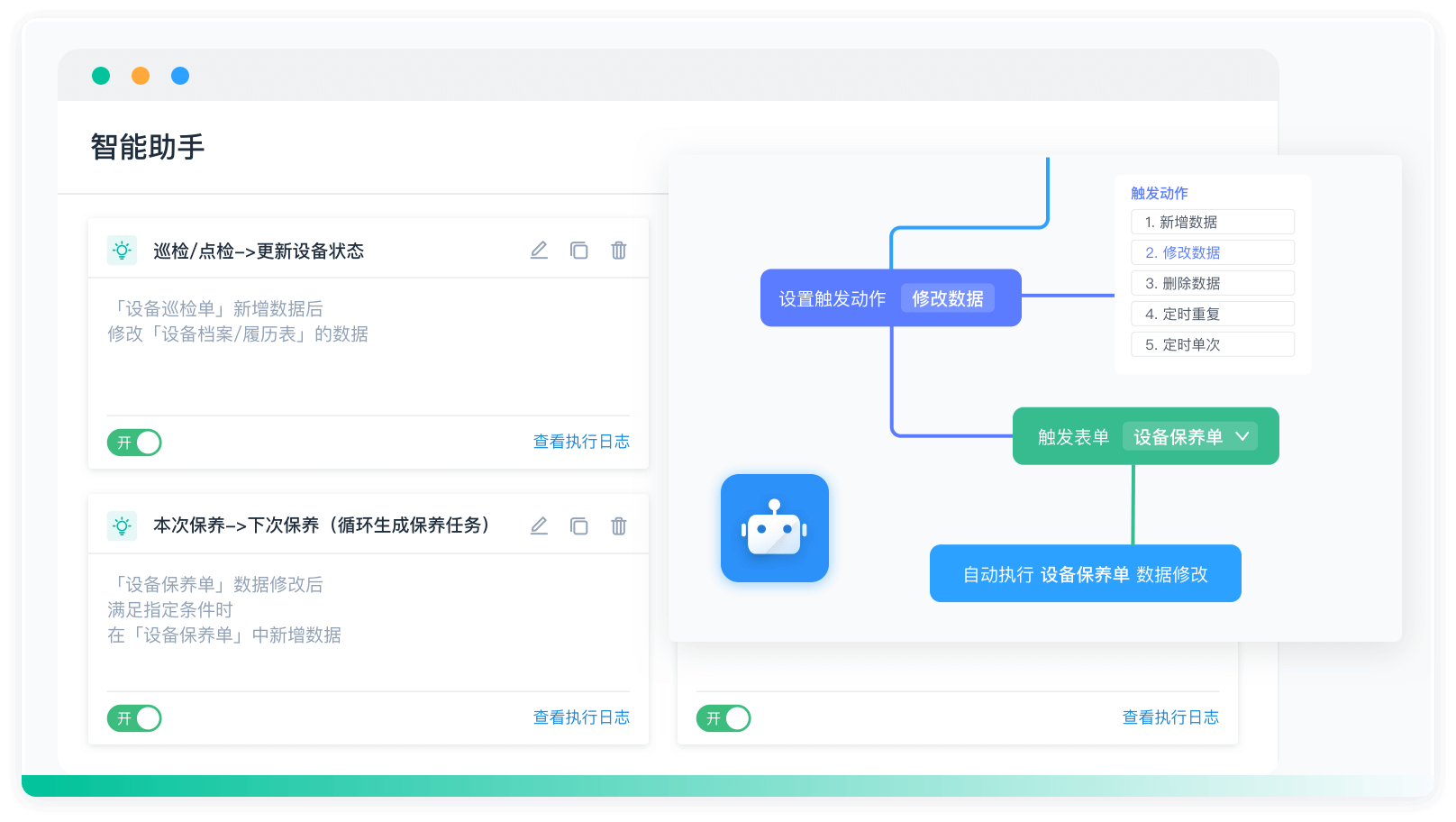

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理