英文仓库管理技巧有哪些

-

1. 仓库管理技巧概述

仓库管理是确保仓库高效运转和库存得以控制的关键方面。以下是一些英文仓库管理技巧,可以帮助提高工作效率:

2. 使用条码技术

条码技术是现代仓库管理系统中不可或缺的一部分。通过为每个库存商品分配一个唯一的条形码,可以轻松追踪和管理库存。员工只需扫描条码,就能快速准确地定位商品的位置,从而提高了拣货和发货的速度。

3. 实施ABC分类法

ABC分类法是一种根据库存商品的重要性和价值将其分为不同类别的方法。A类商品通常是销量较高,价值较大的商品,应当放置在仓库易于获取的位置。而C类商品则是销量较低,价值较低的商品,可以存放在仓库的角落或高架位上。

4. 优化仓库布局

合理的仓库布局可以提高仓库的空间利用率和工作效率。根据商品的不同尺寸和重量,合理规划货架和存储区域,确保相似商品之间的存放位置相邻,减少工作人员在仓库中的移动距离。

5. 实施定期盘点

定期盘点是确保库存数据准确性和避免库存损失的重要措施。通过定期对库存进行盘点,及时发现并处理库存偏差和损耗,确保仓库管理系统中的库存数据与实际库存保持一致。

6. 建立安全库存

建立安全库存是为了应对突发情况和避免缺货而采取的预防措施。根据历史销量和供应商交货时间等因素,合理确定安全库存水平,确保仓库始终能够满足客户需求。

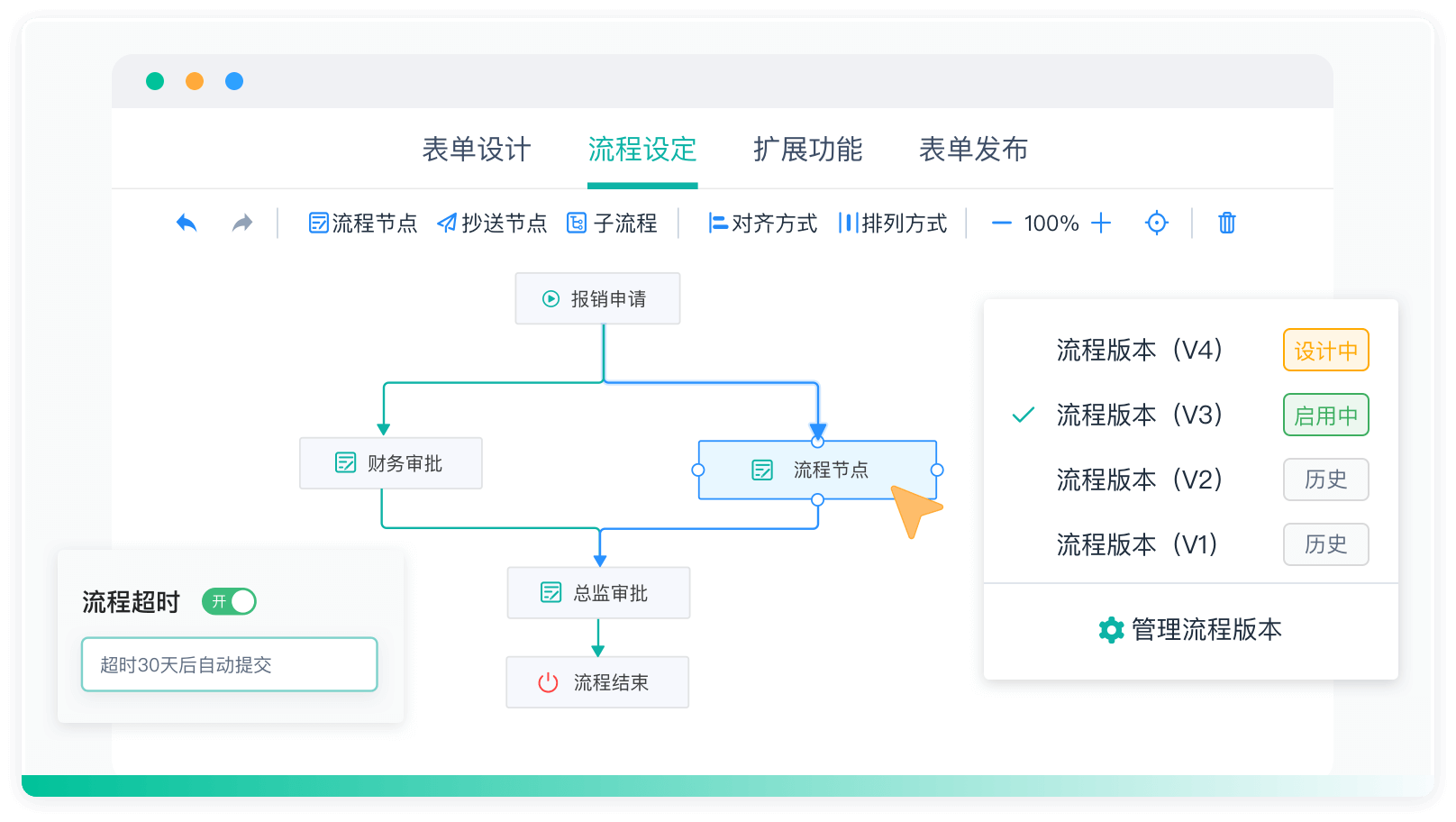

7. 使用仓库管理系统

仓库管理系统是现代仓库管理的重要工具,能够帮助记录库存数据、优化订单处理流程、提高拣货准确性等。选择一款功能强大的仓库管理系统,并确保员工都熟练掌握其操作方法,以提高工作效率和精度。

8. 建立标准作业流程

建立标准作业流程可以帮助规范仓库管理流程、提高工作效率并降低错误率。员工应按照标准操作程序进行操作,以确保所有任务都按照既定流程进行,同时便于员工培训和监督。

9. 培训和激励员工

员工是仓库管理的关键,他们的专业素质和工作积极性直接影响仓库的运转效果。定期进行员工培训,提高他们的技能水平;同时通过激励措施激发其工作动力,提高工作效率和质量。

结语

以上是一些英文仓库管理技巧,通过合理应用这些技巧,可以提高仓库的管理效率和库存控制水平,从而有效降低成本、提高客户满意度。在实际工作中,根据具体情况灵活运用这些技巧,不断优化和改进仓库管理工作。

1年前 -

Effective warehouse management is essential for ensuring the smooth operation of a business. Here are some key techniques to improve English warehouse management:

-

Utilize Warehouse Management Systems (WMS): Implementing a robust WMS can greatly enhance warehouse efficiency by automating tasks such as inventory tracking, order processing, and workflow management.

-

Optimize Layout and Storage: Organize the warehouse layout in a logical and efficient manner to minimize travel time and increase productivity. Use shelving, racks, and bins effectively to maximize storage space.

-

Implement Lean Inventory Practices: Adopt lean inventory management principles to reduce excess stock, minimize storage costs, and improve order fulfillment speed. Just-In-Time inventory systems can be particularly beneficial in this regard.

-

Establish Standard Operating Procedures (SOPs): Develop SOPs for key warehouse processes such as receiving, picking, packing, and shipping. Standardizing procedures ensures consistency, accuracy, and efficiency in operations.

-

Train and Empower Employees: Provide training to warehouse staff on best practices, safety protocols, and equipment operation. Empower employees to make decisions and solve problems independently to promote a culture of continuous improvement.

-

Implement Quality Control Measures: Conduct regular quality checks to ensure accuracy in order fulfillment, prevent errors, and maintain customer satisfaction. Implement barcode scanning and RFID technology for effective tracking and traceability.

-

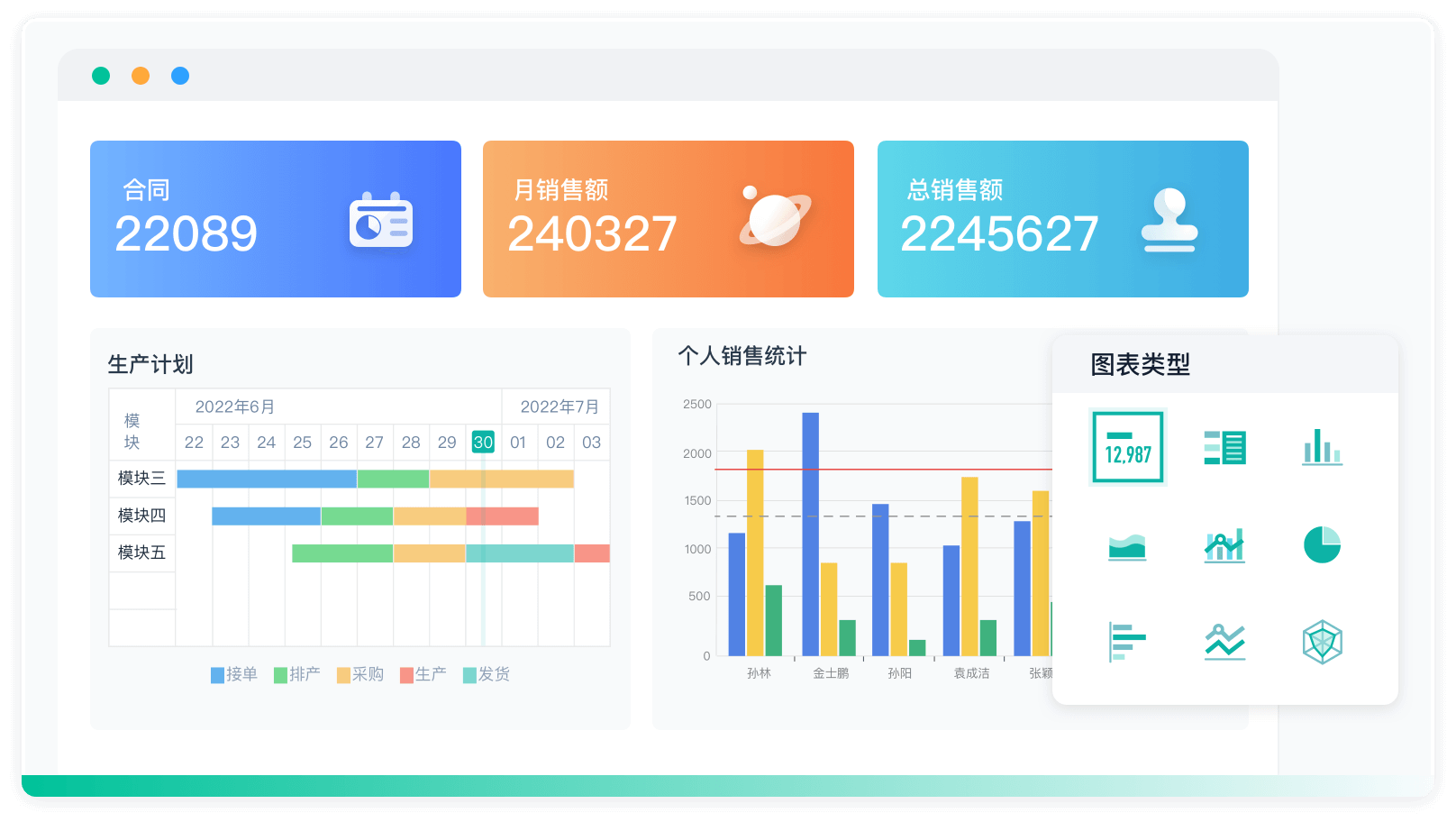

Utilize Performance Metrics: Monitor key performance indicators (KPIs) such as on-time delivery, order accuracy, inventory turnover, and picking efficiency. Use these metrics to identify areas for improvement and drive operational excellence.

-

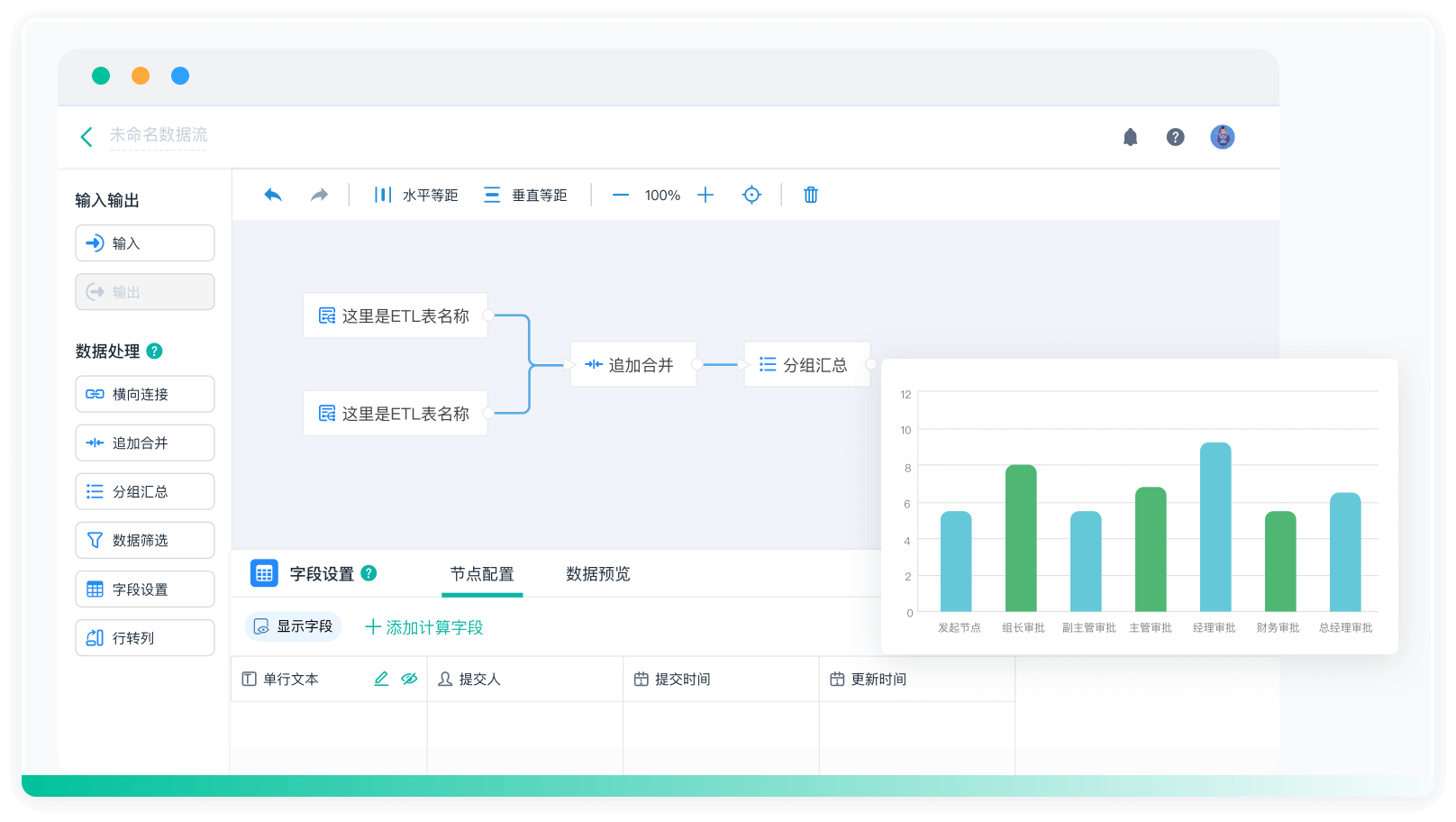

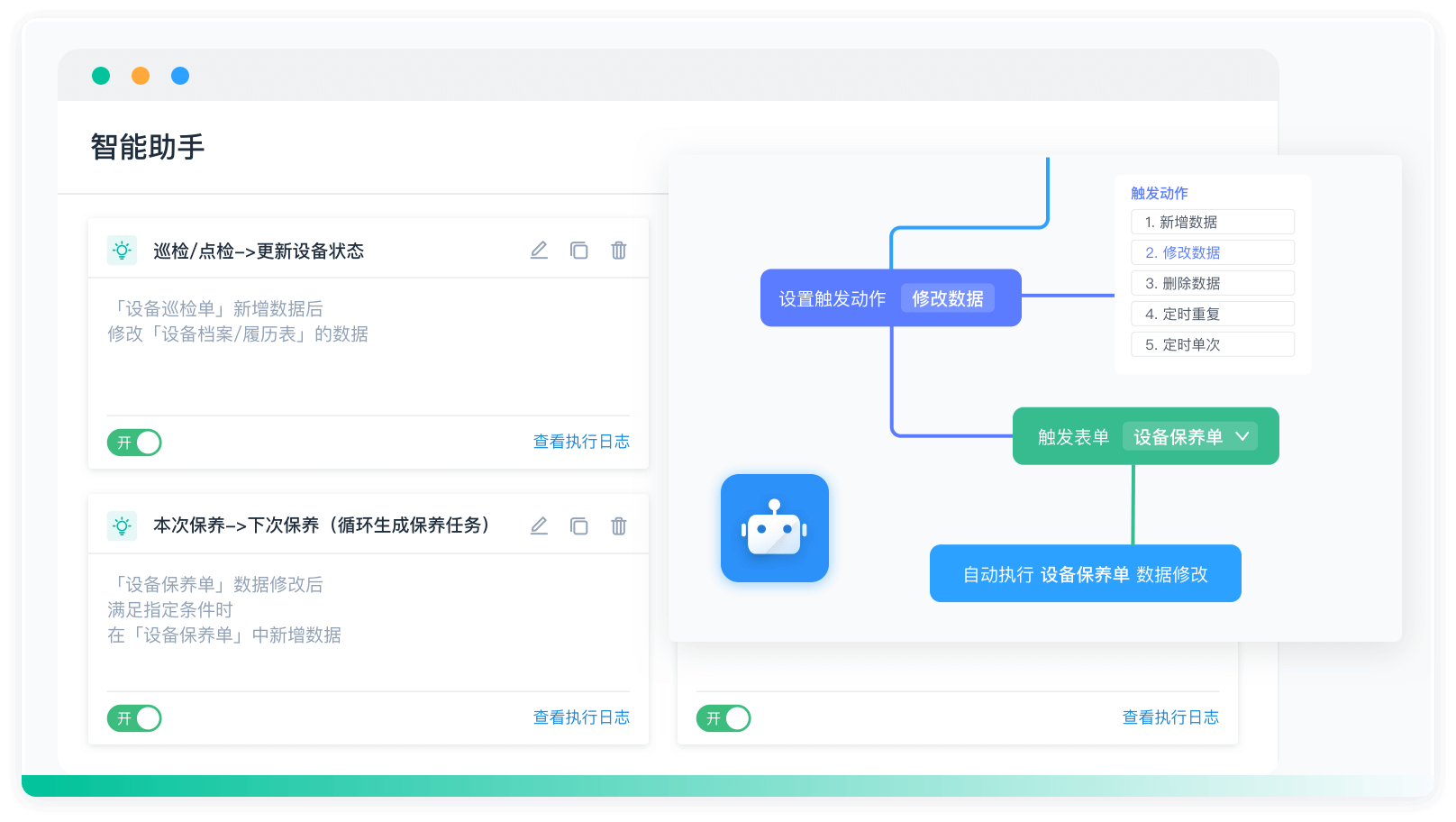

Embrace Technology: Embrace technology solutions such as RFID, IoT, and automation to streamline warehouse operations, enhance visibility, and optimize inventory management. Invest in software for demand forecasting and inventory planning.

-

Implement Cross-Docking: Consider implementing cross-docking practices to reduce inventory holding time and speed up order fulfillment. This strategy can help in minimizing storage costs and improving overall efficiency.

-

Continuous Improvement: Foster a culture of continuous improvement by encouraging feedback from employees, implementing suggestions for process enhancement, and staying updated on industry best practices.

By applying these warehouse management techniques, businesses can enhance operational efficiency, reduce costs, and improve customer satisfaction. It is crucial to adapt these strategies to the specific needs and requirements of the warehouse to achieve optimal results.

1年前 -

-

仓库管理对于任何企业来说都是至关重要的一环。良好的仓库管理可以提高库存周转率、降低成本,提高效率,减少错误和损失。以下是提高英文仓库管理效率的一些建议:

-

Inventory Management System: Implementing an effective inventory management system is crucial for efficient warehouse management. This system should track items in real-time, provide data on stock levels, and facilitate the reordering process. Popular inventory management systems include Fishbowl, NetSuite, and WMS.

-

ABC Analysis: Utilize the ABC analysis technique to categorize inventory based on value and prioritize management efforts. Class A items are high-value and should be closely monitored, while Class C items are low-value and require less attention.

-

Optimized Layout: Organize the warehouse layout in a logical and efficient manner to facilitate easy access to frequently picked items. Utilize bin locations, signage, and labeling to ensure quick identification and retrieval of goods.

-

FIFO/LIFO System: Implement a First In, First Out (FIFO) or Last In, First Out (LIFO) system to manage inventory rotation and prevent product spoilage or obsolescence. This ensures that older stock is used before newer stock.

-

Regular Audits: Conduct regular physical inventory audits to reconcile stock levels, identify discrepancies, and prevent shrinkage. Use cycle counting techniques to continually monitor inventory accuracy and address any issues promptly.

-

Supplier Relationship Management: Cultivate strong relationships with suppliers to ensure timely deliveries, quality products, and competitive pricing. Clear communication and collaboration with suppliers can help streamline the supply chain process.

-

Employee Training: Provide comprehensive training for warehouse staff on proper handling, storage, and picking procedures. Well-trained employees are more efficient, accurate, and less prone to errors, leading to enhanced warehouse productivity.

-

Technology Integration: Utilize technology such as barcode scanners, RFID tags, and warehouse management systems to automate processes, reduce manual errors, and improve overall efficiency. Integration with ERP systems can provide real-time data for better decision-making.

-

Safety Measures: Prioritize warehouse safety by implementing proper training, signage, and equipment to prevent accidents and injuries. A safe working environment not only protects employees but also contributes to a more efficient operation.

-

Performance Metrics: Establish key performance indicators (KPIs) to monitor warehouse performance, such as order fulfillment rate, picking accuracy, and inventory turnover. Regularly analyze these metrics to identify areas for improvement and implement corrective actions.

By incorporating these English warehouse management techniques, businesses can optimize their operations, minimize costs, and achieve greater efficiency in handling inventory.

1年前 -

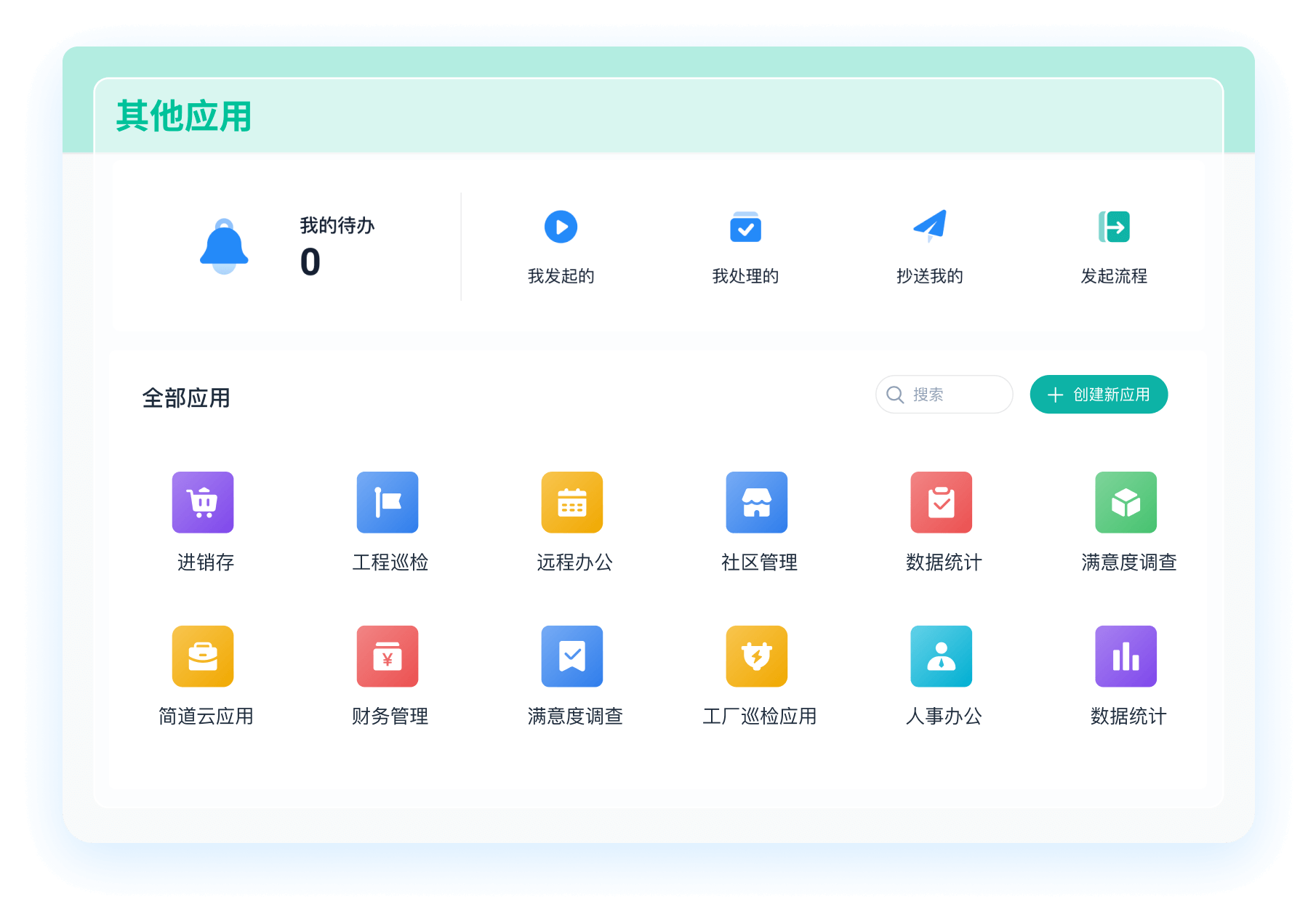

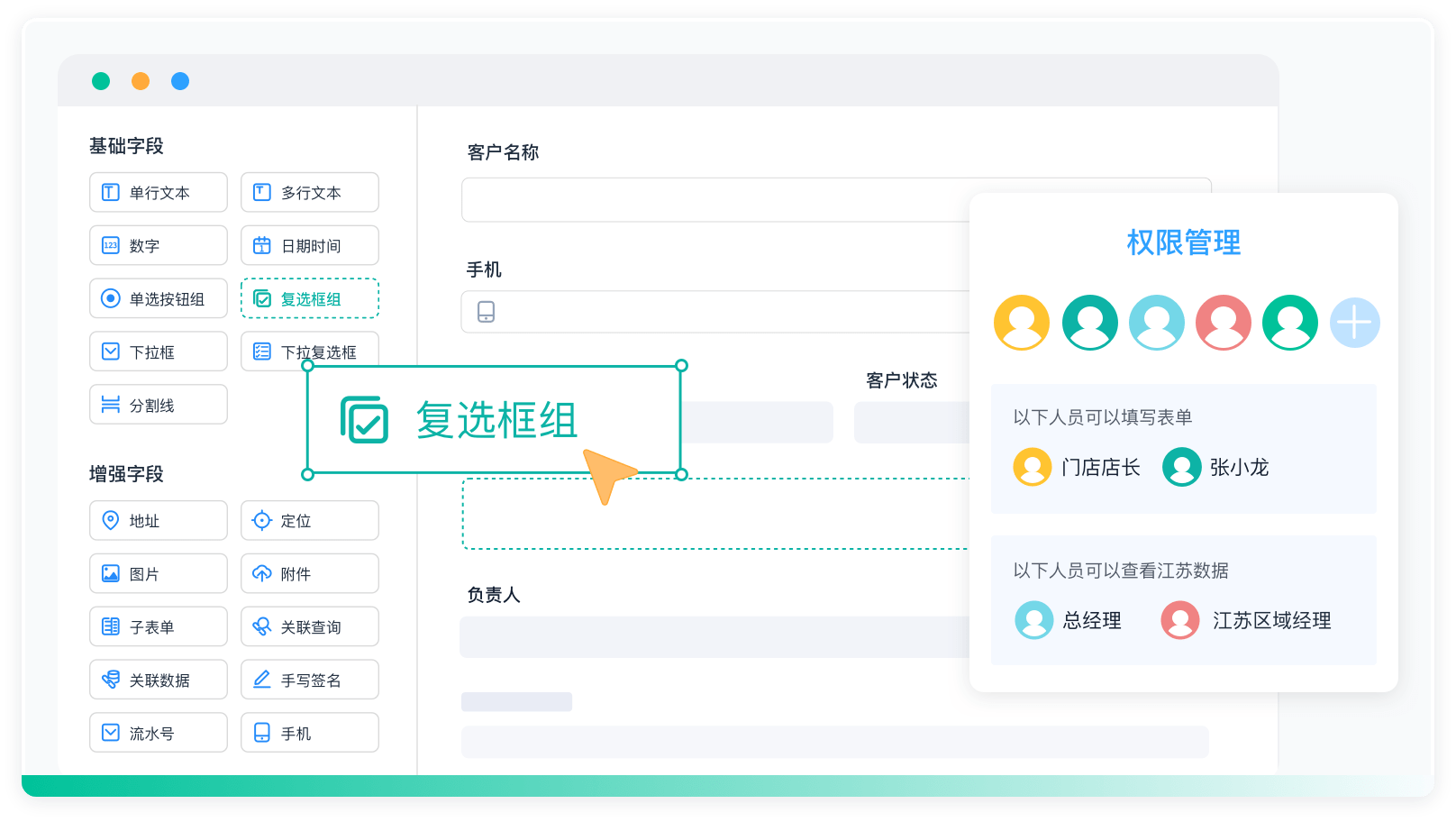

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理