仓库有哪些管理措施呢英语

-

Warehouse Management Measures

Introduction

Warehouse management plays a crucial role in the smooth operation of a company's logistics activities. To ensure efficient handling of inventory and timely order fulfillment, various management measures are put in place. In this article, we will explore some key warehouse management measures that are commonly implemented in a warehouse setting.- Efficient Layout Planning

One of the fundamental aspects of warehouse management is efficient layout planning. A well-designed warehouse layout can optimize the flow of goods, reduce material handling costs, and enhance overall productivity. Key considerations in layout planning include:

- Proper utilization of space: Ensure efficient use of the available space by employing techniques such as vertical storage, mezzanine levels, and racking systems.

- Logical product placement: Group similar products together and place frequently picked items in easily accessible locations to minimize travel time.

- Clear aisle arrangements: Maintain clear and wide aisles for smooth movement of goods and to facilitate the use of material handling equipment.

- Inventory Control

Effective inventory control is essential to prevent stockouts, reduce excess inventory, and streamline reorder processes. Some inventory control measures include:

- Regular stock count: Conduct regular cycle counts or annual physical inventories to verify on-hand inventory levels and identify discrepancies.

- Use of inventory management systems: Implement an inventory management system to track stock levels, monitor product movement, and generate real-time inventory reports.

- ABC analysis: Classify inventory items based on their value and prioritize management efforts on high-value items to ensure optimal stock levels.

- Standard Operating Procedures (SOPs)

Establishing standard operating procedures (SOPs) helps maintain consistency in warehouse operations and aids in training new employees. Some SOPs to consider include:

- Receiving procedures: Define guidelines for receiving goods, inspection processes, and storage location allocation upon receipt.

- Picking and packing procedures: Standardize picking methods, packing requirements, and labeling processes to ensure accuracy and efficiency.

- Shipping procedures: Establish protocols for order consolidation, carrier selection, and documentation to expedite the shipping process.

- Safety and Security Measures

Ensuring a safe working environment and protecting warehouse assets are paramount. Implementing safety and security measures can help prevent accidents, reduce inventory shrinkage, and safeguard employees. Key measures include:

- Employee training: Provide safety training to warehouse staff on proper material handling techniques, equipment operation, and emergency procedures.

- Surveillance systems: Install CCTV cameras, access controls, and alarm systems to monitor warehouse activities and deter unauthorized access.

- Safety equipment: Supply necessary safety equipment such as protective gear, signage, fire extinguishers, and first aid kits to promote a secure working environment.

- Performance Metrics and KPIs

Tracking key performance indicators (KPIs) is essential for evaluating warehouse efficiency and identifying areas for improvement. Some common performance metrics to monitor include:

- Order accuracy: Measure the percentage of orders picked and shipped without errors to gauge the accuracy of warehouse operations.

- Inventory turnover: Calculate the rate at which inventory is consumed or replaced to assess the effectiveness of inventory management practices.

- Labor productivity: Track metrics such as pick rates, packing rates, and order processing times to evaluate workforce productivity and efficiency.

Conclusion

Effective warehouse management measures are critical for optimizing warehouse operations, enhancing productivity, and improving customer satisfaction. By implementing efficient layout planning, inventory control practices, standard operating procedures, safety measures, and performance metrics, companies can streamline their warehouse processes and drive operational excellence.1年前 - Efficient Layout Planning

-

Warehouse management includes a variety of measures designed to optimize the flow of goods in and out of a warehouse, minimize errors, reduce costs, and ensure timely and accurate delivery of products. Below are some key warehouse management measures that are commonly implemented:

-

Inventory Control: This involves maintaining accurate records of all stock items, including their location, quantity, and movements within the warehouse. Using technologies such as barcode scanners, RFID, and warehouse management systems helps ensure real-time visibility of inventory levels.

-

Receiving and Put-away Procedures: Efficient receiving and put-away processes ensure that goods are promptly checked, sorted, and stored in the correct location within the warehouse. This helps prevent delays in order fulfillment and minimizes the risk of stockouts.

-

Order Picking and Packing: Effective order picking involves selecting the right items for each customer order accurately and quickly. Proper packing ensures that goods are packaged securely and labeled correctly before shipment.

-

Cross-Docking: Cross-docking is a technique where incoming goods are directly transferred to outgoing shipments without being stored in the warehouse. This helps reduce handling time and storage costs, allowing for faster order fulfillment.

-

Cycle Counting: Instead of conducting full physical inventories, cycle counting involves regularly counting a portion of the inventory to identify and rectify discrepancies quickly. This helps maintain inventory accuracy and reduces the need for costly and time-consuming annual audits.

-

Slotting Optimization: Slotting optimization involves organizing the warehouse layout to ensure that fast-moving items are placed in easily accessible locations, while slow-moving items are stored in less prime locations. This minimizes travel time for picking operations and improves overall warehouse efficiency.

-

Warehouse Security: Implementing security measures such as access control systems, surveillance cameras, and inventory tracking helps prevent theft, damage, and unauthorized access to the warehouse.

-

Labor Management: Efficient labor management involves proper training of warehouse staff, setting performance targets, and using performance metrics to monitor and improve worker productivity. This helps optimize workforce utilization and reduce labor costs.

-

Vendor Compliance: Working closely with suppliers to ensure they meet quality and delivery standards helps maintain a smooth flow of goods and minimizes disruptions in the supply chain.

-

Performance Metrics: Tracking key performance indicators such as inventory accuracy, order accuracy, on-time delivery, and overall warehouse productivity helps identify areas for improvement and measure the success of warehouse management initiatives.

By implementing these warehouse management measures, businesses can streamline their operations, improve customer satisfaction, and achieve cost savings in their supply chain processes.

1年前 -

-

Warehouse management involves a series of measures and strategies to ensure efficient and effective operations within a warehouse setting. Some of the key management measures that are commonly utilized in warehouses include:

-

Inventory Control: Inventory control is a critical aspect of warehouse management that focuses on monitoring and managing the flow of goods in and out of the warehouse. This involves tracking the movement of inventory, conducting regular stock checks, and implementing systems to prevent stockouts and overstocking.

-

Warehouse Layout and Design: The layout and design of a warehouse play a significant role in determining its efficiency and productivity. Warehouse managers often optimize the layout to facilitate the smooth flow of goods, minimize travel time for employees, and maximize storage capacity.

-

Technology Integration: In recent years, technology has played an increasingly important role in warehouse management. Tools such as barcode scanners, inventory management software, and automated systems help streamline processes, improve accuracy, and enhance overall efficiency in the warehouse.

-

Safety and Security Measures: Maintaining a safe and secure work environment is essential in warehouse management. This includes implementing safety protocols, providing proper training to employees, and securing the warehouse against theft and unauthorized access.

-

Performance Monitoring and KPIs: Warehouse managers often use key performance indicators (KPIs) to track and assess the performance of the warehouse. These metrics can include measures such as order accuracy, on-time delivery, inventory turnover, and labor productivity, which help identify areas for improvement and ensure that the warehouse is operating at peak efficiency.

1年前 -

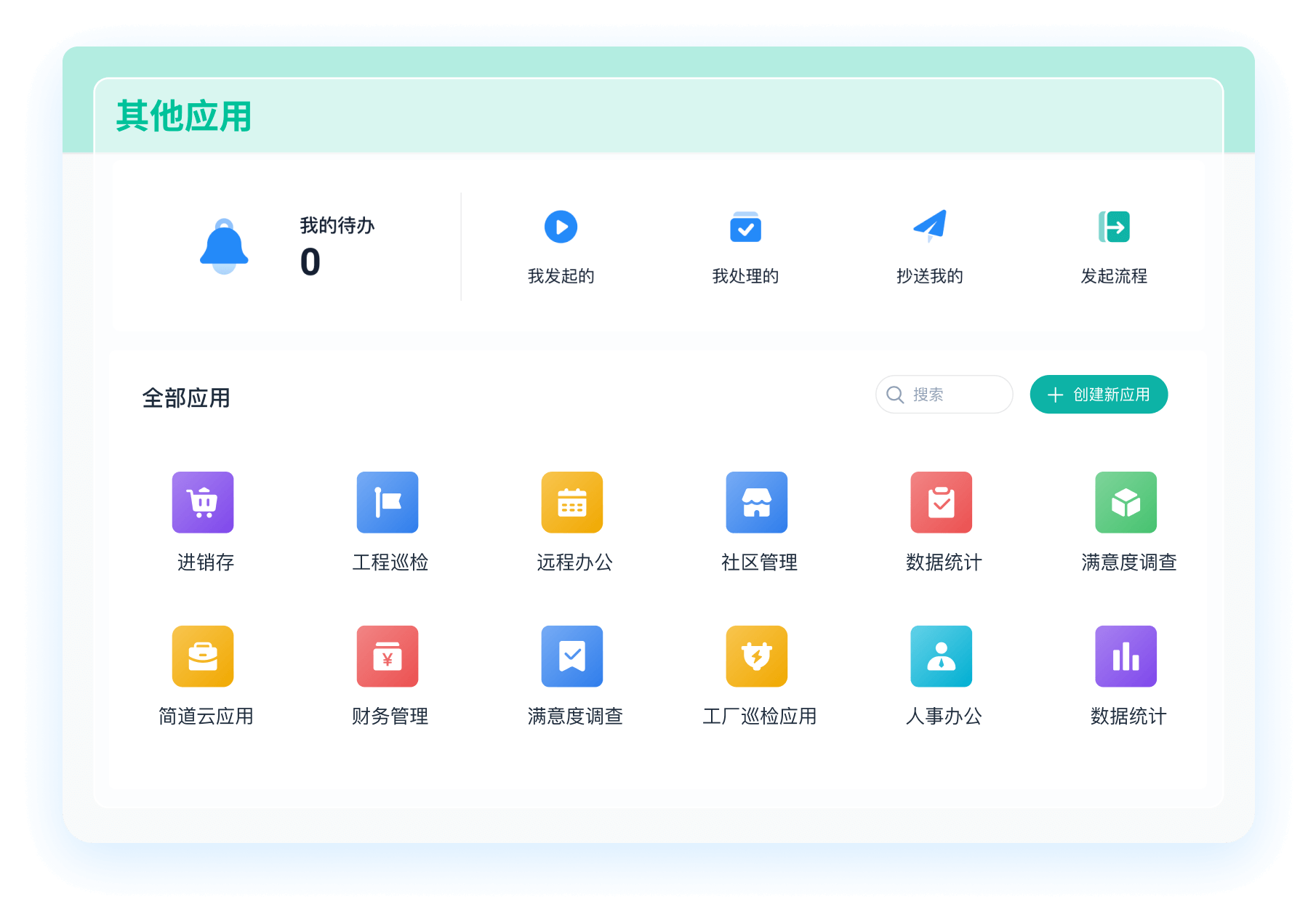

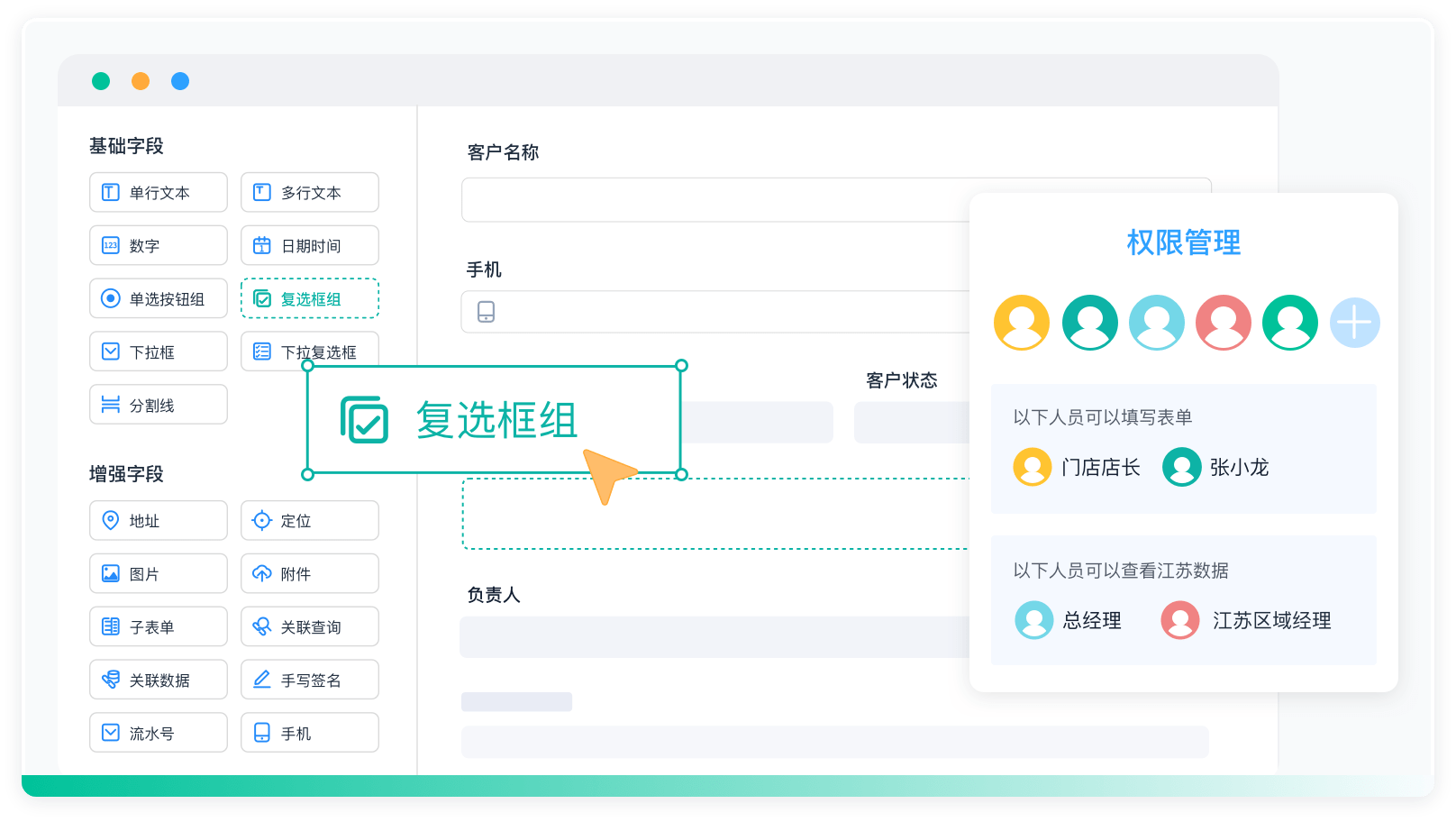

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理