仓库有哪些管理措施呢英文

-

Warehouse Management Measures

Introduction

Warehouse management measures are essential for efficient operations in any warehouse. These measures help in ensuring proper handling, storage, and distribution of goods in a systematic manner. In this article, we will discuss some of the key warehouse management measures that can be implemented to enhance the overall efficiency and productivity of a warehouse.- Inventory Management

Effective inventory management is crucial for maintaining optimal stock levels, reducing stockouts, and minimizing excess inventory. Some key inventory management measures include:

- Regular stock counting and audits to ensure accuracy.

- Implementing an inventory management system to track stock levels in real-time.

- Setting up reorder points and safety stock levels to prevent stockouts.

- Categorizing items based on their demand and value (ABC analysis).

- Implementing FIFO (First In, First Out) or FEFO (First Expired, First Out) principles for perishable goods.

- Space Utilization

Proper space utilization is essential to maximize storage capacity and improve operational efficiency. Some measures to optimize space utilization include:

- Implementing vertical storage solutions such as mezzanines or racks.

- Using appropriate shelving systems based on the size and weight of the products.

- Adopting a slotting system to organize products based on their frequency of movement.

- Implementing cross-docking practices to reduce the need for storage space.

- Order Fulfillment

Efficient order fulfillment processes are essential to meet customer demands in a timely manner. Some measures to streamline order fulfillment include:

- Implementing a barcode system for accurate order picking.

- Utilizing batch picking or zone picking to improve picking efficiency.

- Implementing quality control checks to ensure accurate order fulfillment.

- Utilizing automated sorting and packing systems to speed up order processing.

- Warehouse Layout

An efficient warehouse layout can improve workflow and reduce operational bottlenecks. Some measures for an effective warehouse layout include:

- Designing a layout that minimizes travel time for workers.

- Creating designated areas for receiving, storage, packing, and shipping.

- Ensuring clear aisle markings and signage for easy navigation.

- Implementing safety measures such as fire exits, emergency exits, and first aid stations.

- Technology Integration

Incorporating technology into warehouse operations can enhance efficiency and accuracy. Some technology measures include:

- Implementing a Warehouse Management System (WMS) for inventory tracking and management.

- Using RFID or barcode technology for real-time tracking of inventory.

- Utilizing automation for tasks such as picking, packing, and sorting.

- Implementing a transportation management system for optimized delivery routes.

- Employee Training

Properly trained employees are essential for the smooth functioning of warehouse operations. Some measures for employee training include:

- Providing training on equipment operation, safety procedures, and inventory management.

- Conducting regular refresher courses on warehouse processes and best practices.

- Encouraging employee feedback and suggestions for process improvement.

- Recognizing and rewarding employees for their performance and commitment.

Conclusion

Implementing effective warehouse management measures is essential for optimizing operations and meeting customer demands in a competitive market. By focusing on inventory management, space utilization, order fulfillment, warehouse layout, technology integration, and employee training, warehouses can improve efficiency, accuracy, and overall performance.1年前 - Inventory Management

-

There are several management measures in warehouses to ensure the smooth operation and efficient management of inventory. These management measures include:

-

Inventory Control: This involves keeping track of all items in the warehouse, monitoring stock levels, and managing stock movements to maintain accurate inventory records.

-

Stock Location System: Implementing a systematic stock location system helps in easy identification and retrieval of items. It involves assigning specific locations to different items based on their characteristics and demand.

-

Space Optimization: Warehouse managers need to plan and optimize the use of available space to maximize storage capacity and improve operational efficiency.

-

Just-in-Time (JIT) Inventory System: JIT system aims to reduce excess inventory levels by ordering goods only when they are needed, thus minimizing holding costs and improving cash flow.

-

Barcoding and RFID Technology: Barcoding and Radio-Frequency Identification (RFID) technologies help in accurate tracking and tracing of inventory, leading to better inventory management.

-

Material Handling Equipment: Efficient material handling equipment such as forklifts, pallet jacks, and conveyors play a crucial role in ensuring smooth operations and timely movement of inventory within the warehouse.

-

Quality Control Measures: Implementing quality control measures helps in ensuring that the received goods are of the right quality and quantity, reducing the chances of errors and improving customer satisfaction.

-

Safety and Security Measures: Warehouse safety measures include implementing proper safety protocols, providing training to staff, and ensuring compliance with safety regulations. Security measures involve restricting access to the warehouse, installing surveillance systems, and using security seals to prevent theft.

-

Inventory Replenishment Planning: Warehouse managers need to plan inventory replenishment based on factors such as demand forecasts, lead times, and reorder points to avoid stockouts and overstock situations.

-

Performance Metrics and KPIs: Tracking key performance indicators (KPIs) such as picking accuracy, order fulfillment rate, and inventory turnover helps in evaluating the efficiency of warehouse operations and making data-driven decisions for continuous improvement.

1年前 -

-

Warehouse Management Measures

Warehousing plays a crucial role in the supply chain and efficient warehouse management is essential to ensure smooth operations and cost savings. There are several key warehouse management measures that organizations can implement to enhance efficiency, accuracy, and productivity in their warehouses. Below are some important warehouse management measures:

-

Inventory Control: Implementing robust inventory control measures is essential for effective warehouse management. This includes accurately tracking inventory levels, conducting regular cycle counts and physical inventories, and using technologies such as barcoding and RFID to improve inventory accuracy. By maintaining tight control over inventory levels, organizations can prevent stockouts, reduce carrying costs, and minimize the risk of overstocking.

-

Optimized Layout Design: The layout of a warehouse can have a significant impact on operational efficiency. By designing a layout that minimizes travel time for picking and stocking activities, organizations can improve warehouse productivity. This may involve grouping fast-moving items together, optimizing storage locations based on demand patterns, and ensuring clear aisle markings to facilitate smooth movement of goods.

-

Warehouse Automation: Automation technologies such as conveyor systems, automated guided vehicles (AGVs), and autonomous robots can significantly streamline warehouse operations. By automating repetitive and time-consuming tasks such as order picking, packing, and shipping, organizations can improve efficiency, reduce errors, and free up employees to focus on higher-value activities.

-

Performance Metrics: Establishing key performance indicators (KPIs) and regularly measuring performance against these metrics is essential for monitoring warehouse efficiency and identifying areas for improvement. Common warehouse KPIs include order accuracy, on-time delivery rates, inventory turnover, and labor productivity. By tracking these metrics and analyzing trends over time, organizations can make data-driven decisions to optimize warehouse operations.

-

Employee Training and Development: Investing in employee training and development is crucial for maintaining high operational standards in the warehouse. Providing warehouse staff with training on safety procedures, equipment operation, and best practices for warehouse management can improve productivity, reduce errors, and enhance employee morale. Additionally, offering opportunities for career advancement and skill development can help retain top talent and ensure a motivated workforce.

By implementing these warehouse management measures, organizations can enhance operational efficiency, reduce costs, and improve customer satisfaction. Effective warehouse management is essential for achieving competitive advantage in today's fast-paced business environment.

1年前 -

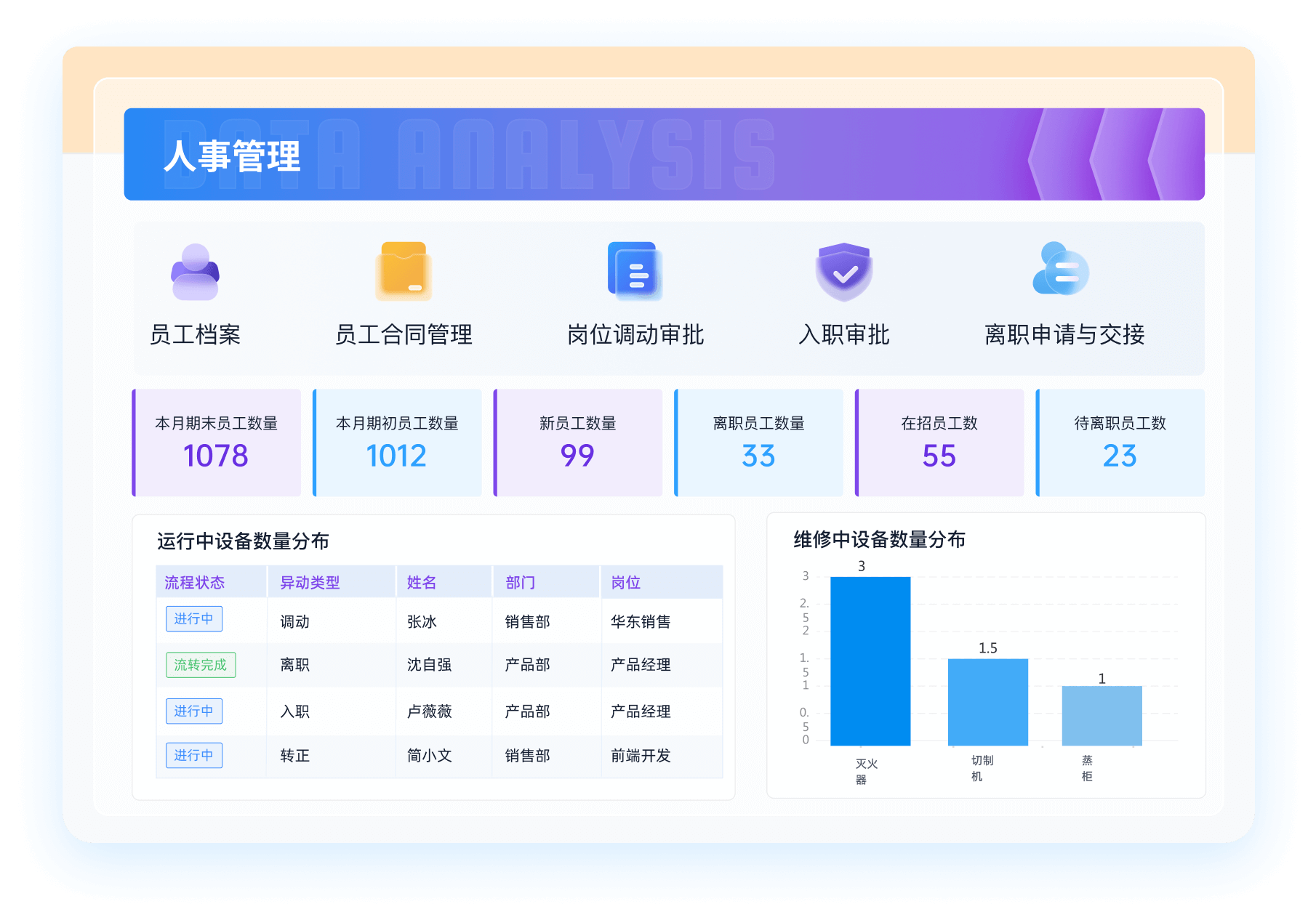

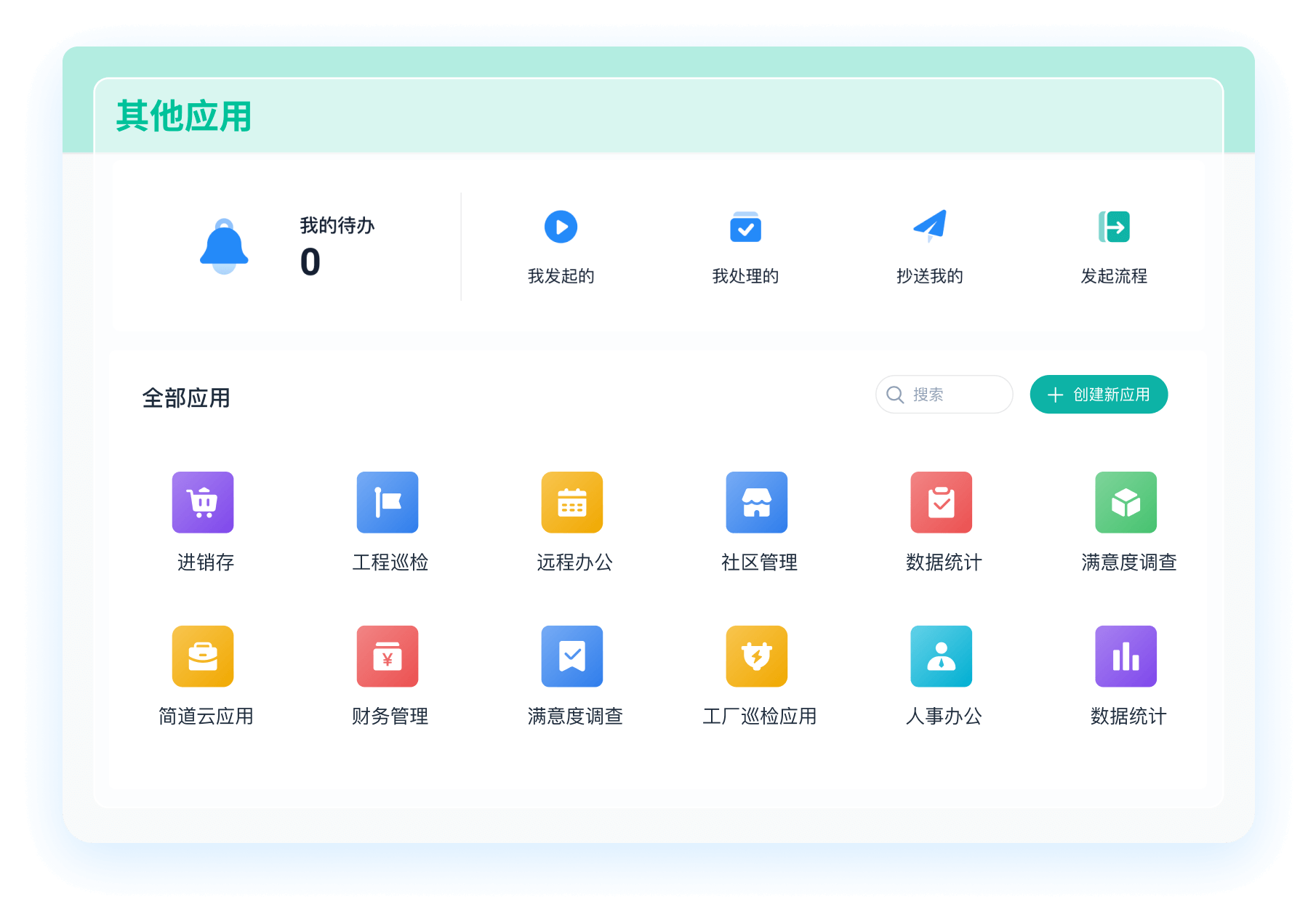

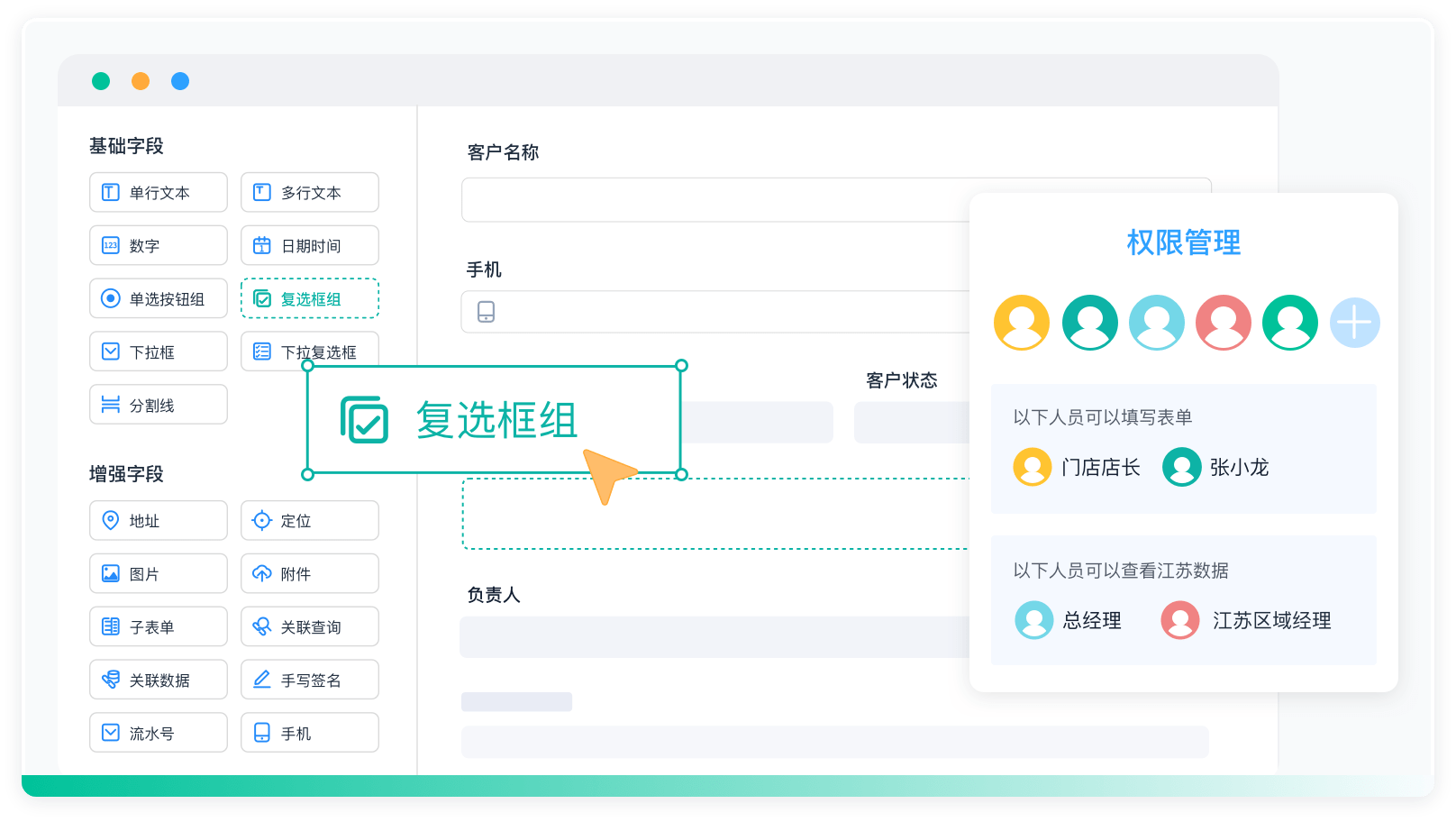

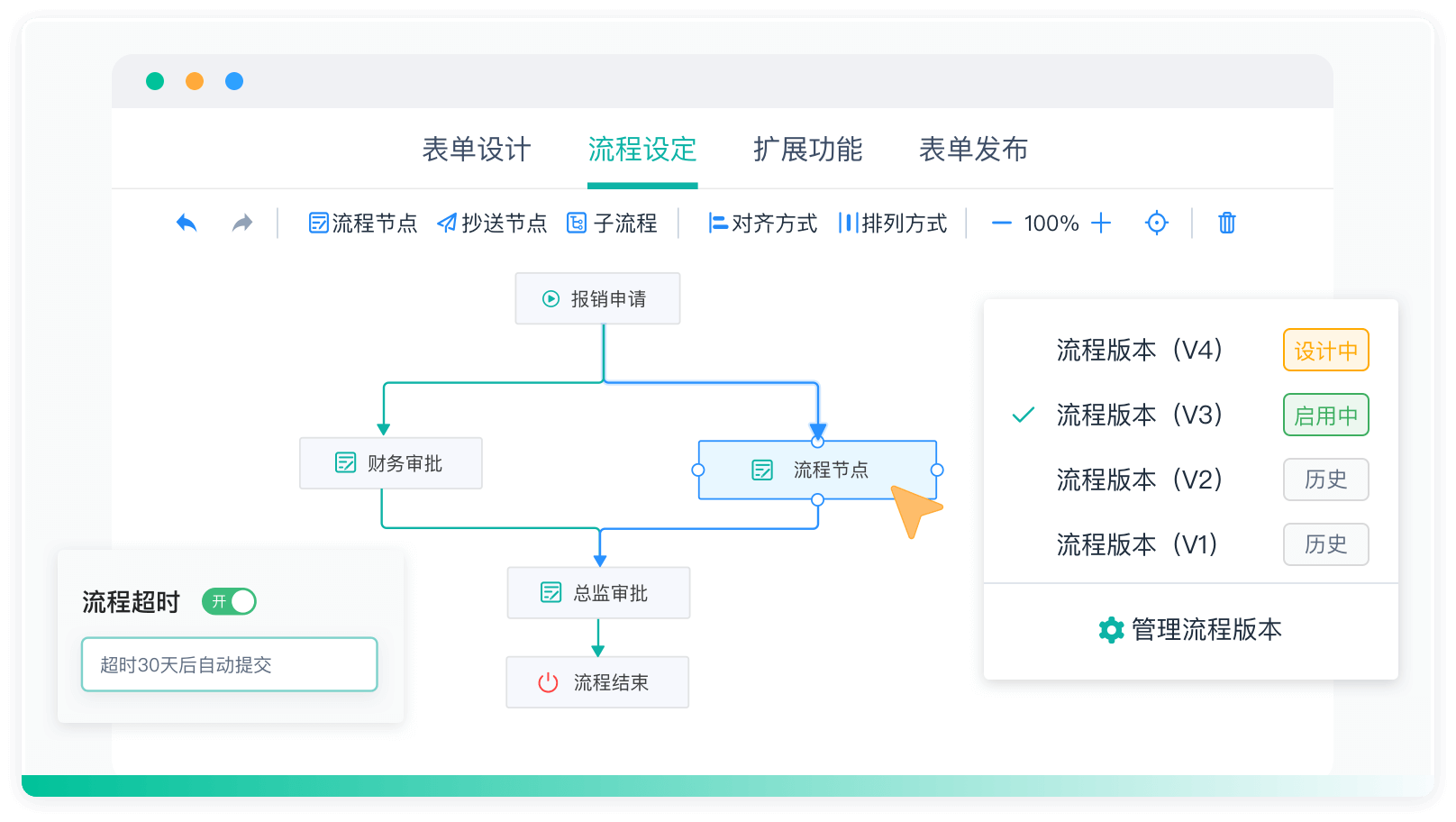

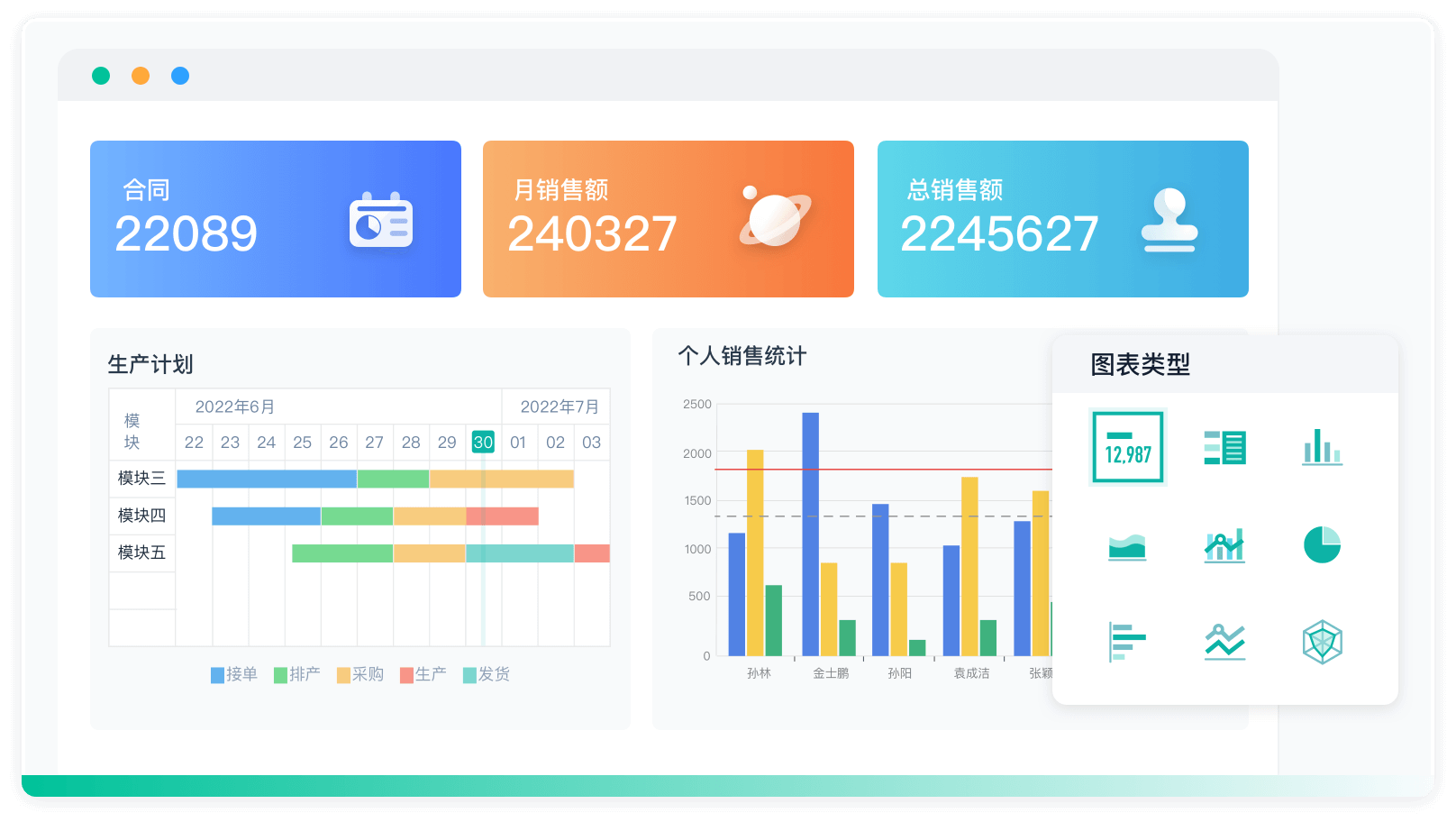

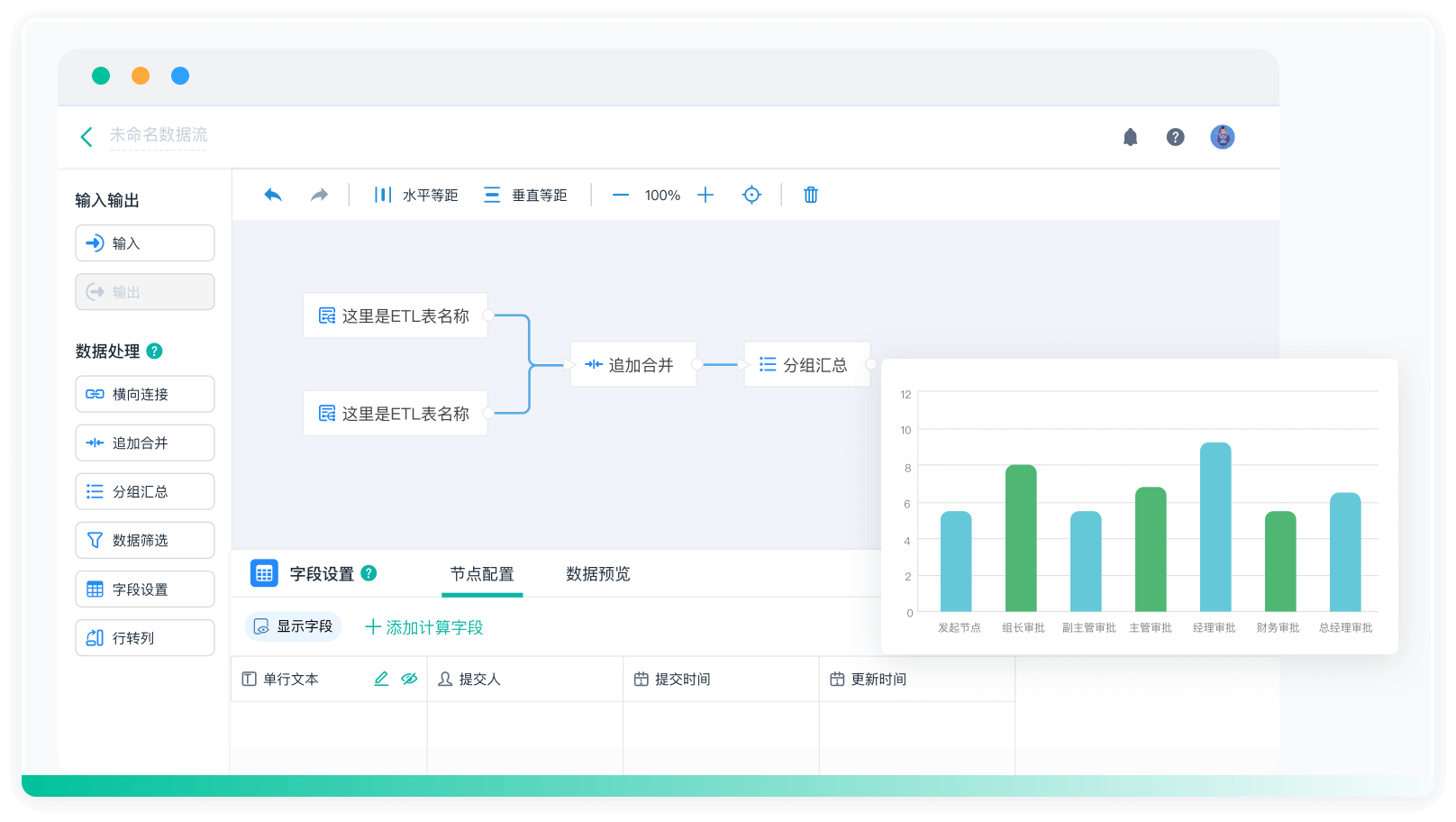

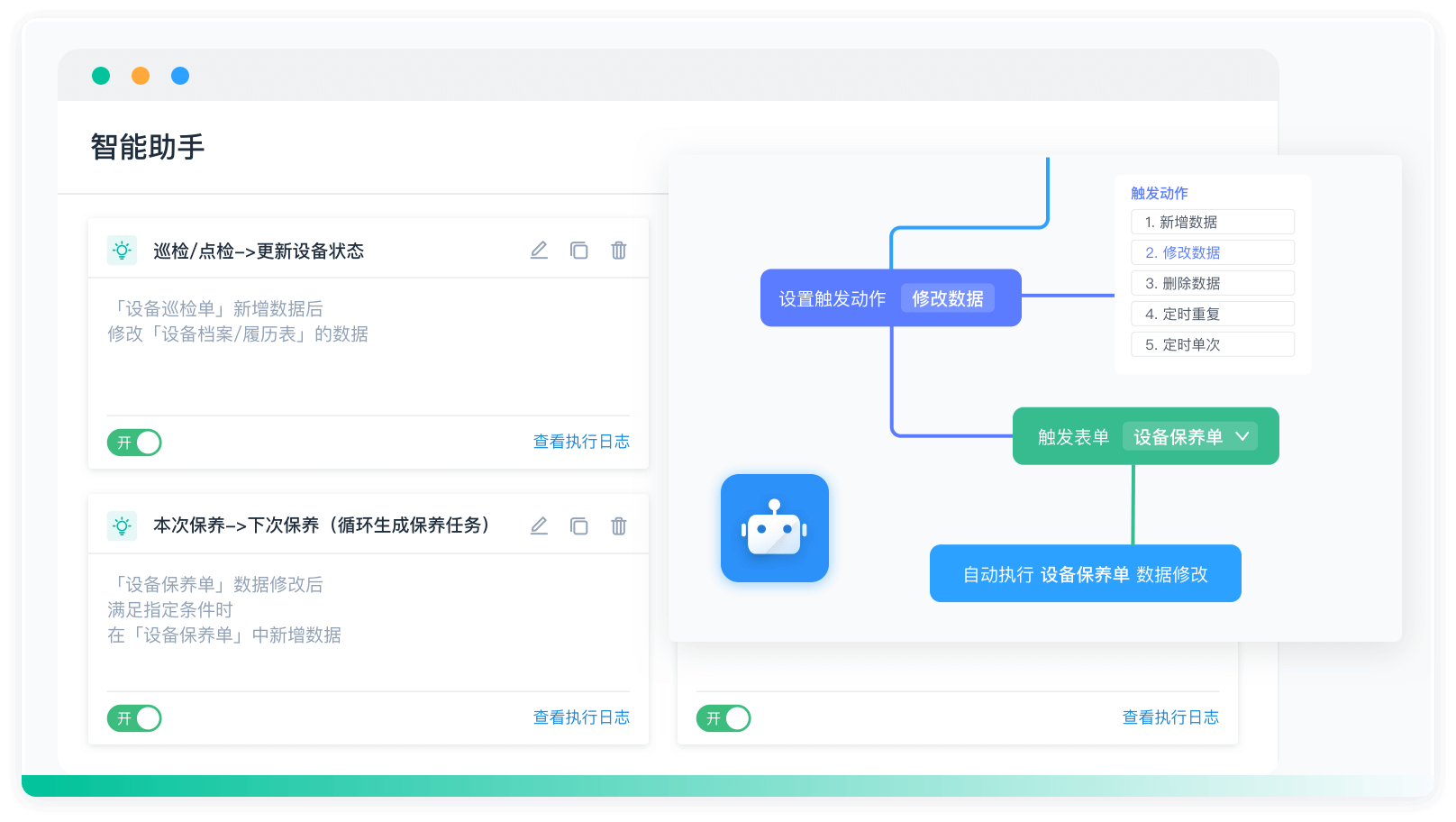

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理