仓库管理有哪些模式呢英文

-

There are several warehouse management systems (WMS) that companies can consider implementing in order to improve the efficiency and productivity of their warehouse operations. Some of the common warehouse management systems include:

-

Paper-based WMS: In this traditional method, all processes are managed and recorded manually using paper forms, documents, and spreadsheets. Although cost-effective, this method is prone to human errors and is time-consuming.

-

Excel-based WMS: Some smaller organizations may use Excel spreadsheets to manage their warehouse operations. While Excel is flexible and customizable, it lacks advanced features that can streamline warehouse processes.

-

Standalone WMS: A standalone WMS is a software application specifically designed for warehouse management. It typically includes features such as inventory tracking, order processing, picking and packing, and shipment tracking.

-

Cloud-based WMS: Cloud-based WMS systems are hosted on remote servers and accessed through a web browser. This allows for real-time data access, scalability, and easier integration with other software systems.

-

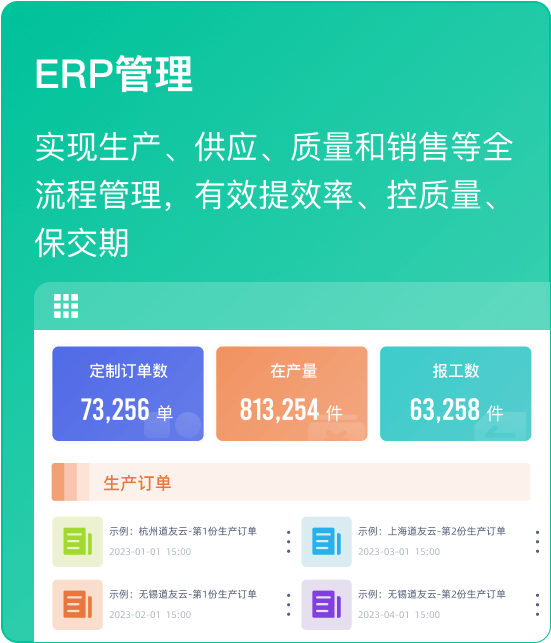

ERP-integrated WMS: Enterprise Resource Planning (ERP) systems often come with integrated WMS modules. This seamless integration allows for the synchronization of data between warehouse operations and other business functions.

-

On-premise WMS: On-premise WMS systems are installed and hosted on the company's own servers and infrastructure. While they offer greater control and security, they require higher initial investments and ongoing maintenance costs.

-

Mobile WMS: Mobile WMS applications run on handheld devices such as smartphones and tablets. They provide warehouse staff with real-time access to inventory data, order updates, and task assignments while on the warehouse floor.

-

RFID-based WMS: Radio-Frequency Identification (RFID) technology can be integrated into a WMS to enable automatic identification and tracking of inventory items using RFID tags and readers. This technology can improve accuracy and efficiency in warehousing processes.

-

Voice-directed WMS: Voice-directed picking systems use speech recognition technology to guide warehouse operators through picking tasks via headsets or mobile devices. This hands-free approach can increase picking accuracy and productivity.

By selecting the most suitable warehouse management system for their specific needs and operations, companies can optimize their warehouse processes, improve inventory accuracy, minimize errors, and ultimately enhance customer satisfaction.

1年前 -

-

仓库管理可以涉及多种不同的模式,其中一些常见的包括:存储模式、拣选模式、装卸模式、库存控制模式和信息管理模式。

存储模式:存储模式涉及如何有效地存放货物以便日常操作。常见的存储模式包括随机存储、区域存储和托盘存储。随机存储指的是将货物存放在仓库中的任何可用空间,适用于各种类型和尺寸的商品。区域存储则是将货物按照类型、尺寸或其他特征进行分区存放,以便快速识别和检索。托盘存储是一种将货物堆叠在托盘上的方式,以便于使用叉车或其他设备进行搬运。

拣选模式:拣选模式涉及如何有效地选择和提取货物以满足订单需求。一些常见的拣选模式包括分区拣选、波次拣选和批量拣选。分区拣选是将拣选区域分为多个不同的区域,每个区域负责处理特定类型或特定订单的货物。波次拣选是将订单按照相似的特征进行分组,以便批量处理以提高效率。批量拣选是一种将相同类型或相似属性的货物批量拣选并打包的方式,常用于大宗商品或定期发货。

装卸模式:装卸模式涉及如何有效地将货物运入和运出仓库。常见的装卸模式包括手工装卸、自动化装卸和混合装卸。手工装卸是指由人工进行装卸操作,适用于小型或轻型货物。自动化装卸则是利用设备或机器进行货物的装卸,可提高效率和减少人力成本。混合装卸则是结合手工和自动化装卸方式,根据货物类型和数量进行选择。

库存控制模式:库存控制模式涉及如何有效地管理仓库中的库存水平以确保及时供应和降低存储成本。一些常见的库存控制模式包括先进先出(FIFO)、后进先出(LIFO)和定期盘点。FIFO模式是指先进入仓库的货物先被销售或使用,有利于保持库存新鲜度和减少库存积压。LIFO模式则是后进入仓库的货物先被销售或使用,常用于易腐烂或易过时的商品。定期盘点是定期对仓库库存进行检查和核对,以确保库存准确性和避免盗窃或损耗。

信息管理模式:信息管理模式涉及如何管理仓库中的信息流和数据流,以便实时跟踪库存和订单状态。一些常见的信息管理模式包括物流管理系统(WMS)、自动识别和数据采集(AIDC)和云计算技术。WMS系统是一种专门用于管理仓库操作的软件系统,可以帮助实现库存控制、订单处理和运输管理。AIDC技术则包括条形码、RFID等自动识别技术,可以提高货物追踪和库存管理的准确性和效率。云计算技术则是基于云服务的信息管理方式,可以实现实时数据共享和远程访问,提高仓库管理的灵活性和可扩展性。

总的来说,仓库管理的模式可以根据实际情况和需求进行选择和组合,以提高仓库的运作效率和服务质量。

1年前 -

Warehouse management refers to the process of controlling and overseeing the operations within a warehouse. There are several different warehouse management models that companies can implement to streamline their processes and improve efficiency. Some common warehouse management models include:

-

Cross-Docking Model: In this model, incoming goods are unloaded from inbound vehicles and directly loaded onto outbound vehicles with minimal or no storage time in the warehouse. This approach helps to reduce handling and storage costs, as well as minimize the risk of inventory errors.

-

Just-In-Time (JIT) Model: The JIT model aims to minimize inventory holding costs by only ordering or producing goods when they are needed. This requires close coordination between suppliers and customers to ensure that materials arrive exactly when they are needed for production or delivery.

-

ABC Inventory Model: This model categorizes inventory based on its value and importance. A items are high-value items with low inventory levels, B items are moderate in value and inventory, and C items are low in value but may have high inventory levels. By prioritizing inventory management based on these categories, companies can optimize their storage space and ensure that critical items are always available.

-

Wave Picking Model: In wave picking, orders are grouped into "waves" based on factors such as order priority, location, or SKU. Warehouse staff then pick all the items for each wave at the same time, increasing efficiency and reducing travel time within the warehouse.

-

Cross-Functional Team Model: In this model, warehouse management involves collaboration between different departments within the company, such as logistics, operations, and IT. By breaking down silos and fostering communication between these teams, companies can improve overall warehouse performance and responsiveness to customer needs.

These are just a few examples of warehouse management models that companies can adopt to optimize their operations. Each model has its own benefits and challenges, so it's important for companies to carefully evaluate their specific needs and goals before implementing a new warehouse management strategy.

1年前 -

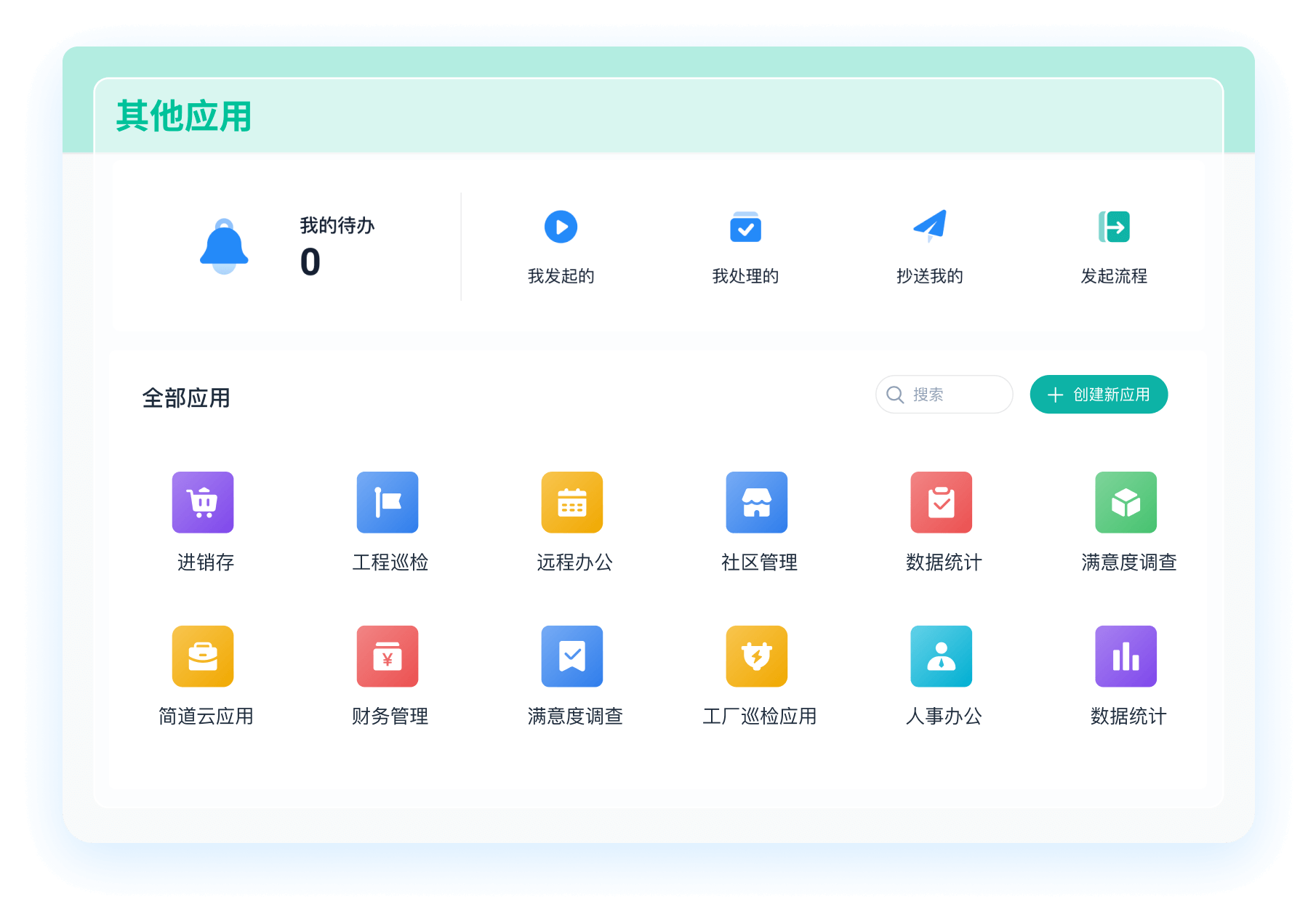

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理