仓库管理有哪些模式呢英语

-

There are several warehouse management modes, or systems, that businesses can implement to efficiently manage their inventory and logistics operations. Below are some common warehouse management modes:

-

Wave Picking

Wave picking involves processing multiple orders simultaneously in "waves." Orders are grouped together based on similar characteristics, such as delivery route, product type, or order priority. This allows for more efficient picking and packing processes since workers can pick multiple orders at once. -

Batch Picking

Batch picking involves picking multiple orders at the same time but separately. Workers go through the warehouse once to pick all the items for the orders and then sort them out into individual orders before packing. This reduces travel time and increases picking efficiency. -

Zone Picking

Zone picking divides the warehouse into different zones, and each worker is assigned to a specific zone. When an order comes in, it is divided into zones, and each picker is responsible for picking items only from their designated zone. The picked items are then brought to a central packing area for consolidation. -

Cross-Docking

Cross-docking is a method where incoming goods are directly transferred from the receiving dock to the outbound shipping dock with minimal handling or storage time in between. This method is beneficial for fast-moving goods or perishable items that do not require long-term storage. -

Just-In-Time (JIT)

Just-In-Time is a strategy where items are received, processed, and shipped out as soon as an order is placed. This method helps to reduce inventory carrying costs and the risk of overstocking. However, it requires tight coordination with suppliers and logistics partners to ensure timely deliveries. -

Radio Frequency Identification (RFID)

RFID technology uses radio waves to identify and track items within the warehouse. RFID tags are attached to the products or pallets, allowing for real-time tracking and inventory management. This technology can improve accuracy, speed, and visibility in the warehouse. -

Automated Storage and Retrieval System (AS/RS)

AS/RS is a system that uses automated machinery to store and retrieve goods from specific locations within the warehouse. This system can significantly increase storage capacity, reduce labor costs, and improve inventory accuracy and speed of operations. -

Multi-Channel Fulfillment

With the rise of e-commerce, businesses often need to fulfill orders through multiple channels, such as online sales, brick-and-mortar stores, and wholesale distribution. A multi-channel fulfillment strategy involves managing inventory across various channels to ensure efficient order processing and timely deliveries.

In conclusion, choosing the right warehouse management mode depends on factors such as the nature of the products, order volumes, storage capacity, and operational efficiency goals. By implementing an effective warehouse management system, businesses can optimize their operations, reduce costs, and enhance customer satisfaction.

1年前 -

-

仓库管理有多种不同的模式和方法,每种都有其优缺点,可根据企业的实际情况选择最适合的。以下是常见的几种仓库管理模式:

-

批量存储模式(Batch Storage):这是最常见的仓库存储模式之一,即以批量的形式存储货物。这种模式有助于简化存储过程,但可能会导致存取效率较低。

-

随机存储模式(Random Storage):与批量存储相反,随机存储模式是将货物存放在任意可用的位置,而不是按照特定的顺序。这种模式可以提高存取效率,但管理起来会更加复杂。

-

动态存储模式(Dynamic Storage):这种模式结合了批量存储和随机存储的优点,根据货物的特性和需求,动态地调整存储位置。这样可以在保持存取效率的同时,最大限度地利用仓库空间。

-

质数分区模式(Zone Picking):在大型仓库中常用的一种模式,将仓库划分为多个质数,每个质数由专门的团队负责。当订单到达时,不同的质数同时拣选货物,提高了拣货速度和效率。

-

交叉码头模式(Cross Docking):这种模式将货物从供应商运到仓库后,立即转运到相应的客户,而不需要存储或处理。这有助于减少库存和加快物流速度,但对供应链协调要求较高。

-

自动化仓库模式(Automated Warehouse):利用自动化设备和系统管理仓库,如自动存取货架、AGV(自动导引车)等。这种模式可以提高工作效率和减少人为错误,但投资和维护成本较高。

-

混合存储模式(Mixed Storage):结合不同的存储模式,根据货物特性灵活选择合适的存储方式。这种模式适用于仓库需要同时满足不同需求的情况。

以上是常见的几种仓库管理模式,企业可以根据自身的实际情况选择最适合的模式或结合多种模式来进行综合管理。

1年前 -

-

There are several warehousing management modes commonly used in the logistics industry to optimize warehouse operations and improve efficiency. Here are some of the key warehouse management modes:

-

Cross-Docking:

Cross-docking is a logistics practice where products from a supplier or manufacturing facility are distributed directly to customers or retail stores with minimal handling and storage time in the warehouse. This mode reduces inventory holding costs and streamlines the flow of goods through the supply chain. -

Just-in-Time (JIT) Inventory Management:

Just-in-Time inventory management is a strategy that aims to minimize inventory levels by only ordering or producing goods as they are needed in the production process or to fulfill customer orders. This mode helps reduce holding costs, prevent overstocking, and improve cash flow. -

Automated Warehousing:

Automated warehousing utilizes technology such as robotics, conveyor systems, and automated storage and retrieval systems (AS/RS) to efficiently manage and move inventory within the warehouse. This mode improves accuracy, speed, and productivity in handling goods, leading to faster order fulfillment and reduced labor costs. -

Multi-Channel Fulfillment:

Multi-channel fulfillment involves fulfilling customer orders from multiple sales channels, such as online stores, retail stores, and wholesale distribution, using a single inventory pool. This mode integrates inventory management and order processing systems across different channels to optimize order fulfillment and provide a seamless customer experience. -

Cross-Functional Team Collaboration:

Cross-functional team collaboration involves various departments within an organization, such as logistics, inventory management, operations, and sales, working together to optimize warehouse operations and meet customer demand. This mode fosters communication, cooperation, and alignment of goals across different functions to improve overall warehouse performance. -

Vendor-Managed Inventory (VMI):

Vendor-Managed Inventory is a supply chain management mode where the supplier is responsible for monitoring and replenishing the customer's inventory based on agreed-upon inventory levels and demand forecasts. This mode helps reduce stockouts, inventory carrying costs, and supply chain disruptions, while improving inventory turnover and customer satisfaction.

These are some of the common warehouse management modes used in the logistics industry to enhance operational efficiency, reduce costs, and meet customer demand effectively. Each mode has its unique benefits and challenges, and the choice of the most suitable mode depends on factors such as the nature of the products, customer requirements, and the organization's overall supply chain strategy.

1年前 -

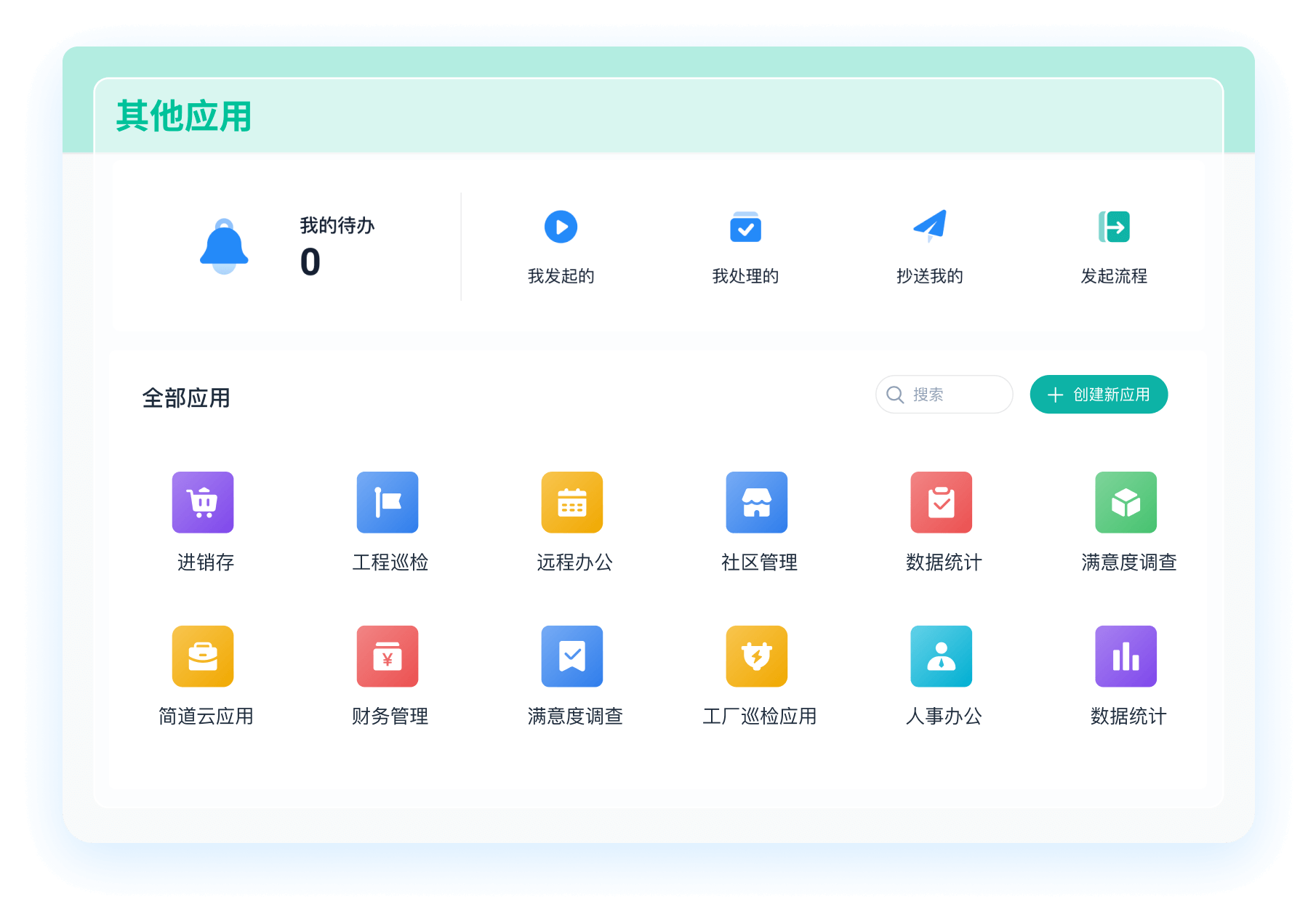

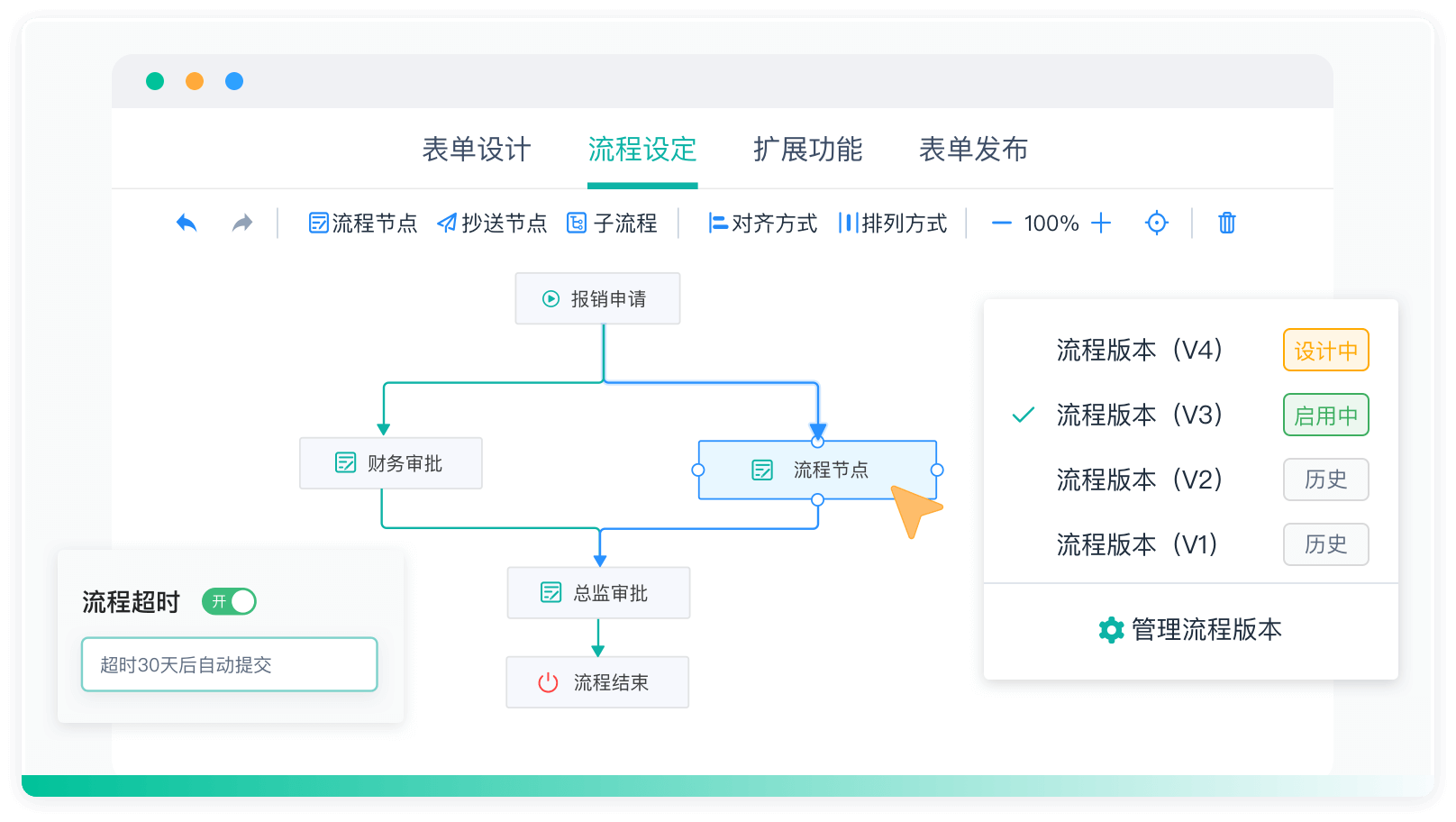

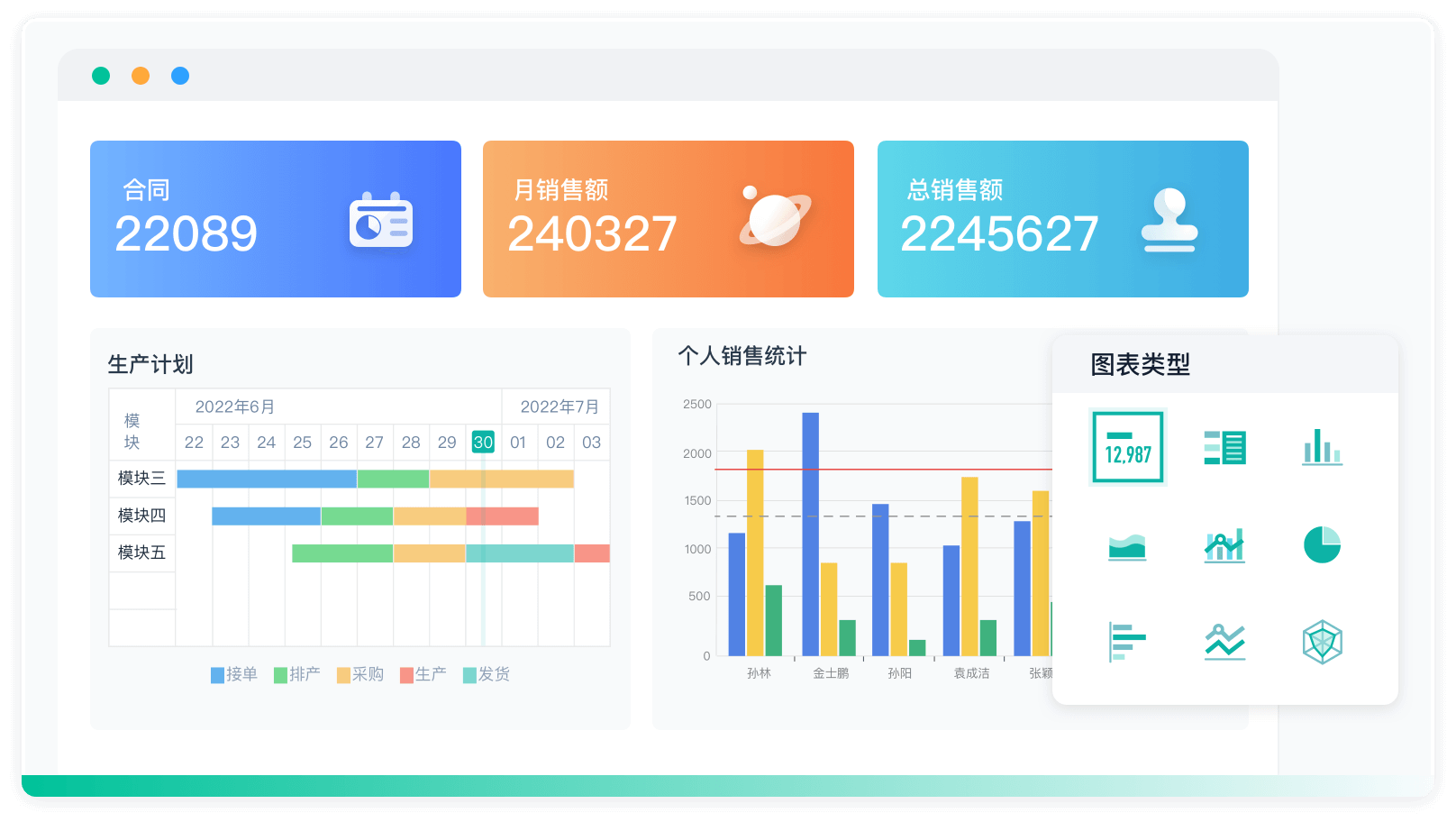

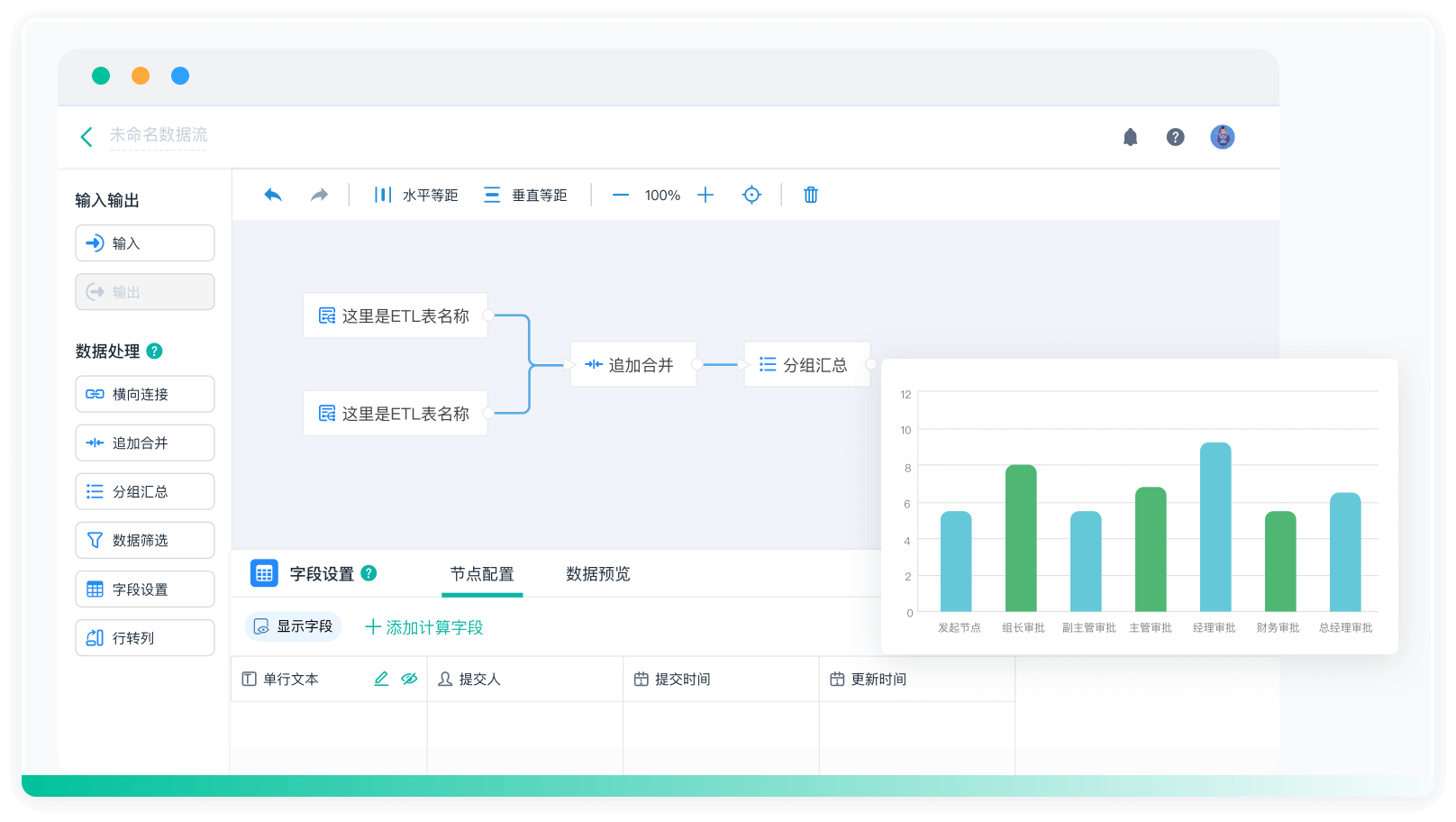

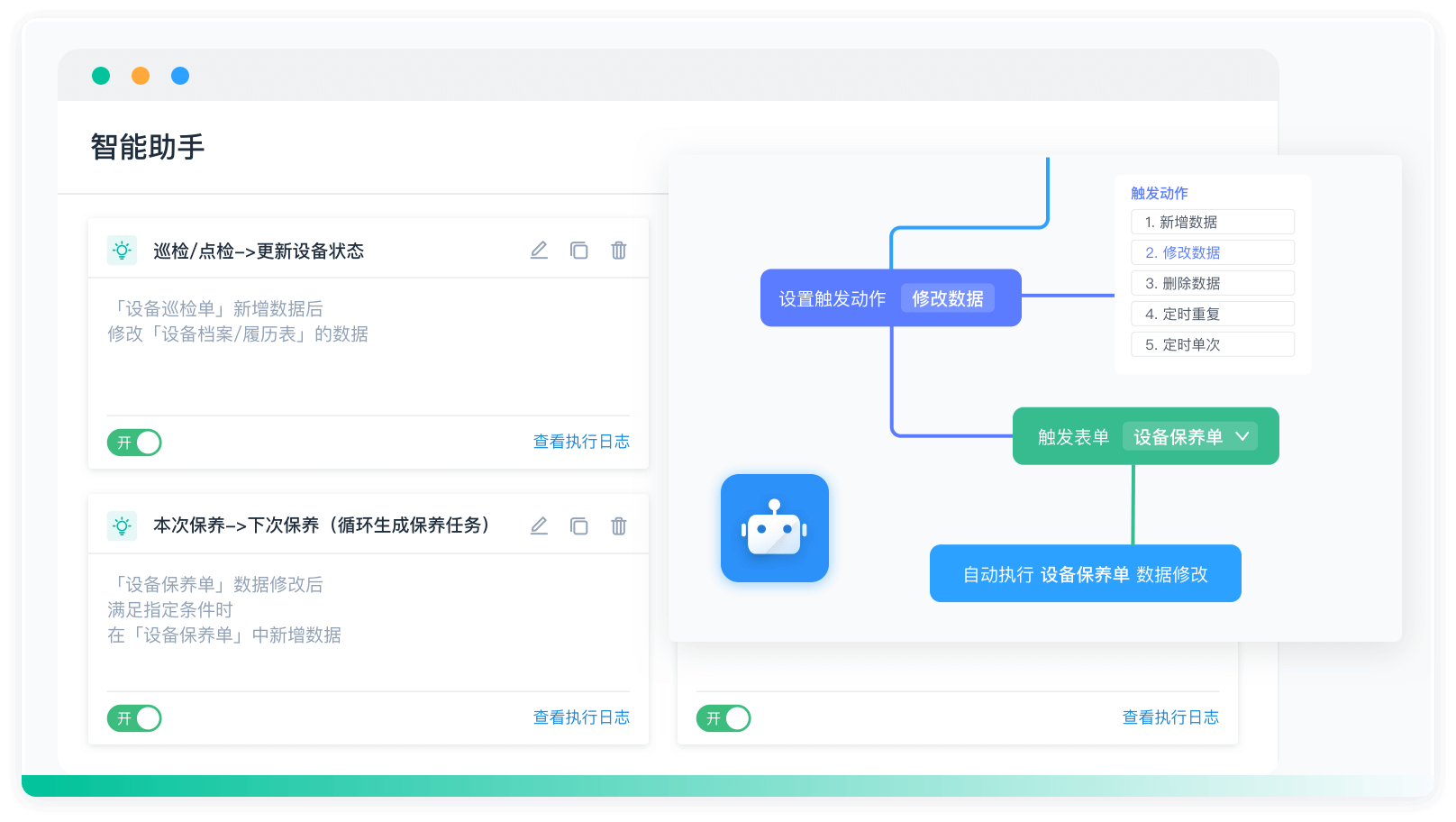

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理