仓库归哪个区管理呢英语

-

Which Area Does the Warehouse Belong to and How is it Managed?

Introduction

In every organization, the warehouse plays a crucial role in the smooth functioning of operations. It acts as a hub where raw materials are stored, processed, and distributed to various departments. However, determining which area manages the warehouse and how it is managed can vary depending on the organizational structure and industry. In this comprehensive guide, we will delve into the various aspects of warehouse management, including the types of warehouses, the role of different departments, and the key strategies for effective warehouse management.Types of Warehouses

Before understanding which area manages the warehouse, it is essential to grasp the different types of warehouses that exist. Warehouses can be classified into the following categories based on their functionality:-

Private Warehouses: These are owned and operated by a single organization to store their products exclusively. Private warehouses provide complete control over inventory management and security.

-

Public Warehouses: Public warehouses are facilities that offer storage and handling services to multiple organizations on a rental basis. These warehouses are beneficial for companies that do not want to invest in their storage facilities.

-

Bonded Warehouses: These warehouses are authorized by the government to store imported goods without paying duties until the goods are released for sale in the local market. Bonded warehouses are crucial for international trade.

-

Automated Warehouses: Automated warehouses utilize advanced technology such as robotics, conveyor belts, and automated storage and retrieval systems (AS/RS) to streamline operations and enhance efficiency.

-

Distribution Centers: Distribution centers focus on rapid order fulfillment and serve as hubs for distributing products to retailers or directly to customers.

-

Climate-Controlled Warehouses: These warehouses are equipped with temperature and humidity control systems to store perishable goods, pharmaceuticals, and other sensitive products.

Role of Different Departments in Warehouse Management

Warehouse management involves coordination among various departments within an organization to ensure seamless operations. The following departments play a crucial role in managing a warehouse effectively:-

Procurement Department: The procurement department is responsible for sourcing raw materials, components, and products that are stored in the warehouse. They work closely with suppliers to ensure timely deliveries and optimal inventory levels.

-

Inventory Control Department: The inventory control department oversees the monitoring, tracking, and replenishment of stock in the warehouse. They use inventory management software to maintain accurate records and prevent stockouts or overstock situations.

-

Operations Department: The operations department manages the day-to-day activities in the warehouse, including receiving goods, storage, order picking, packing, and shipping. They focus on maximizing efficiency and minimizing errors in warehouse operations.

-

Logistics Department: The logistics department is responsible for transportation, distribution, and supply chain management. They coordinate the movement of goods between the warehouse, suppliers, manufacturing facilities, and customers.

-

IT Department: The IT department plays a crucial role in warehouse management by implementing and maintaining warehouse management systems (WMS), barcode scanners, RFID technology, and other tools to streamline operations and track inventory accurately.

Warehouse Management Strategies

Effective warehouse management requires the implementation of various strategies to optimize operations and improve productivity. Some key strategies include:-

Layout Optimization: Designing an efficient warehouse layout that minimizes travel time, maximizes storage capacity, and ensures smooth flow of goods is essential for enhancing productivity.

-

Inventory Optimization: Implementing techniques such as ABC analysis, cycle counting, and just-in-time inventory management helps in optimizing inventory levels, reducing storage costs, and minimizing stockouts.

-

Pick and Pack Process: Streamlining the pick and pack process by grouping orders, optimizing picking routes, and using technology such as voice picking or pick-to-light systems can significantly improve order accuracy and fulfillment speed.

-

Employee Training: Providing comprehensive training to warehouse staff on safety procedures, equipment operation, inventory management practices, and use of warehouse technology is crucial for smooth operations and efficient task execution.

-

Performance Metrics: Establishing key performance indicators (KPIs) such as order cycle time, order accuracy, inventory turnover, and fill rate helps in monitoring warehouse performance, identifying bottlenecks, and implementing continuous improvements.

Conclusion

In conclusion, the management of a warehouse involves a collaborative effort among different departments within an organization to ensure efficient operations and timely fulfillment of customer orders. By understanding the types of warehouses, the role of different departments, and implementing effective warehouse management strategies, organizations can enhance productivity, reduce costs, and gain a competitive edge in the market. Proper warehouse management is essential in today's fast-paced business environment to meet customer demands and drive business growth.1年前 -

-

Warehouses are managed by the logistics or supply chain department in a company. The logistics department is responsible for overseeing the storage, distribution, and movement of goods within the warehouse. They handle inventory management, order processing, transportation coordination, and overall efficiency of the warehouse operations. In larger organizations, there may be a dedicated warehouse management team or a separate department focusing solely on warehouse operations. This ensures proper organization, supervision, and optimization of the warehouse activities to meet the company's supply chain needs.

1年前 -

Warehouse is managed by the logistics department in a company. The logistics department is responsible for overseeing the storage, distribution, and transportation of goods within the organization. Here are five key points about how warehouses are managed by the logistics department:

-

Inventory Management: The logistics department is responsible for managing the inventory in the warehouse. This includes keeping track of stock levels, organizing inventory, and ensuring that there is enough stock to meet customer demand.

-

Warehouse Operations: The logistics department oversees the day-to-day operations of the warehouse. This includes receiving incoming goods, storing them in the appropriate locations, picking and packing orders, and shipping them out to customers.

-

Safety and Security: The logistics department is also responsible for ensuring the safety and security of the warehouse. This includes implementing safety protocols, training employees on safe practices, and implementing security measures to prevent theft or damage to goods.

-

Efficiency and Optimization: The logistics department works to optimize warehouse operations for greater efficiency. This may involve implementing new technologies, redesigning warehouse layouts, or streamlining processes to reduce costs and improve productivity.

-

Compliance and Regulation: The logistics department ensures that the warehouse operates in compliance with all relevant regulations and industry standards. This includes adhering to health and safety regulations, maintaining accurate records, and following best practices for inventory management and storage.

Overall, the logistics department plays a critical role in managing warehouses to ensure that goods are stored, handled, and distributed efficiently and effectively to meet customer needs.

1年前 -

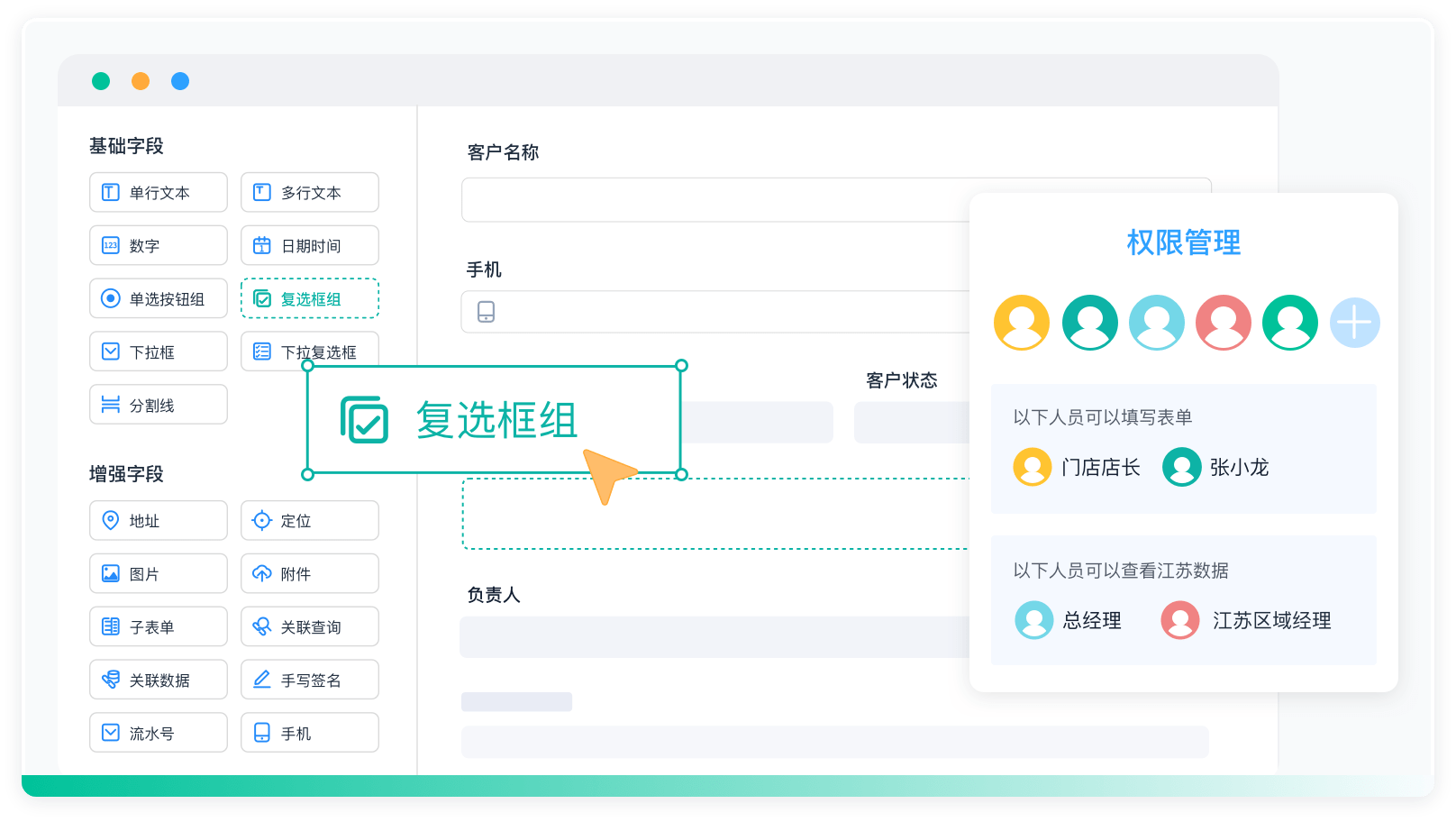

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理