仓库有多少种管理方法英文

-

There are several different methods for managing warehouses. Some of the most common methods include:

- ABC Analysis

- Just-In-Time (JIT) Inventory Management

- Cross-Docking

- Vendor-Managed Inventory (VMI)

- Dropshipping

- Kanban System

Each of these methods has its own benefits and drawbacks, and the best method for a particular warehouse will depend on the specific needs and goals of the business. Below, we will discuss each of these warehouse management methods in detail.

ABC Analysis

ABC Analysis is a method of inventory management that categorizes items based on their value and importance. Items are classified into three categories: A, B, and C.

- Category A items are high-value items that make up a small percentage of total inventory but account for a large percentage of inventory costs.

- Category B items are moderate-value items that make up a moderate percentage of total inventory and account for a moderate percentage of inventory costs.

- Category C items are low-value items that make up a large percentage of total inventory but account for a small percentage of inventory costs.

By classifying items in this way, businesses can prioritize their efforts and resources on managing the most important items more effectively.

Just-In-Time (JIT) Inventory Management

Just-In-Time (JIT) Inventory Management is a method of inventory control in which materials and products are delivered to a warehouse or production facility just in time for use. This method aims to minimize inventory levels and reduce waste by only stocking items that are needed immediately. JIT inventory management can help companies save on storage costs and improve efficiency by ensuring that inventory turnover is high and that the right products are available when needed.

Cross-Docking

Cross-docking is a logistics strategy in which products from multiple suppliers are unloaded at a warehouse facility and then immediately loaded onto outbound trucks for delivery to customers. This method eliminates the need for storing products in the warehouse, as they are transferred directly from incoming trucks to outgoing trucks. Cross-docking can help reduce handling and storage costs, speed up delivery times, and improve overall efficiency in the supply chain.

Vendor-Managed Inventory (VMI)

Vendor-Managed Inventory (VMI) is a supply chain management technique in which the supplier takes responsibility for managing the inventory levels of their products at the customer's warehouse. The supplier is responsible for monitoring inventory levels, restocking products, and adjusting orders based on demand forecasts. VMI can help companies reduce carrying costs, minimize stockouts, and improve overall supply chain efficiency by allowing the supplier to have more control over inventory levels and replenishment processes.

Dropshipping

Dropshipping is a retail fulfillment method in which a store does not keep the products it sells in stock. Instead, when a store sells a product using the dropshipping model, it purchases the item from a third party and has it shipped directly to the customer. This method eliminates the need for storing inventory, as products are shipped directly from the supplier to the customer. Dropshipping can help businesses reduce upfront costs, minimize storage space requirements, and offer a wider variety of products to customers without the need for holding inventory.

Kanban System

The Kanban System is a lean manufacturing method for managing and controlling inventory levels in a production environment. The system uses visual cues, such as cards or bins, to signal when products or materials need to be restocked or replenished. When inventory levels reach a certain threshold, a signal is sent to the supplier to replenish the stock. The Kanban System helps companies reduce waste, improve efficiency, and maintain optimal inventory levels by ensuring that materials are replenished only when needed.

In conclusion, there are various methods for managing warehouses, each with its own advantages and potential applications. By understanding the different warehouse management methods and selecting the most appropriate method for their specific needs, businesses can improve efficiency, reduce costs, and optimize their supply chain operations.

1年前 -

There are several methods for managing warehouses.

1年前 -

仓库有多种管理方法,以下是其中一些常见的:

-

ABC 分类法:将库存按照销售频率或者价值进行划分,分为A类(高销售频率或高价值)、B类(中等销售频率或价值)和C类(低销售频率或价值)。这种方法可以帮助仓库管理人员更好地控制库存,优化库存周转率。

-

Just-In-Time (JIT)管理方法:这是一种精益生产理念,旨在减少库存水平,降低库存成本,提高生产效率。通过及时交付零部件和原材料,JIT可以帮助仓库实现及时生产,减少库存积压。

-

跨境电商仓库管理方法:针对跨境电商仓库的特点,包括高周转率、不断变化的库存品类和需求等,需要采用灵活的管理方法。比如,通过智能化仓库系统管理库存,实现准确、高效的订单处理和配送。

-

虚拟仓库管理方法:随着电子商务和物流行业的发展,虚拟仓库管理方法也变得越来越重要。虚拟仓库通过云端技术,实现无纸化管理、实时库存信息更新和智能化分拣,提高仓库运营效率。

-

货架管理系统(RMS):货架管理系统结合自动化设备和软件系统,帮助仓库管理人员优化货物存储和取货流程,提高空间利用率和操作效率。 RMS可以实现自动分拣、智能导航等功能,提升仓库管理的精度和效率。

这些管理方法各有特点,可以根据不同的仓库特点和需求选择合适的管理方法来提升仓库运营效率和降低成本。

1年前 -

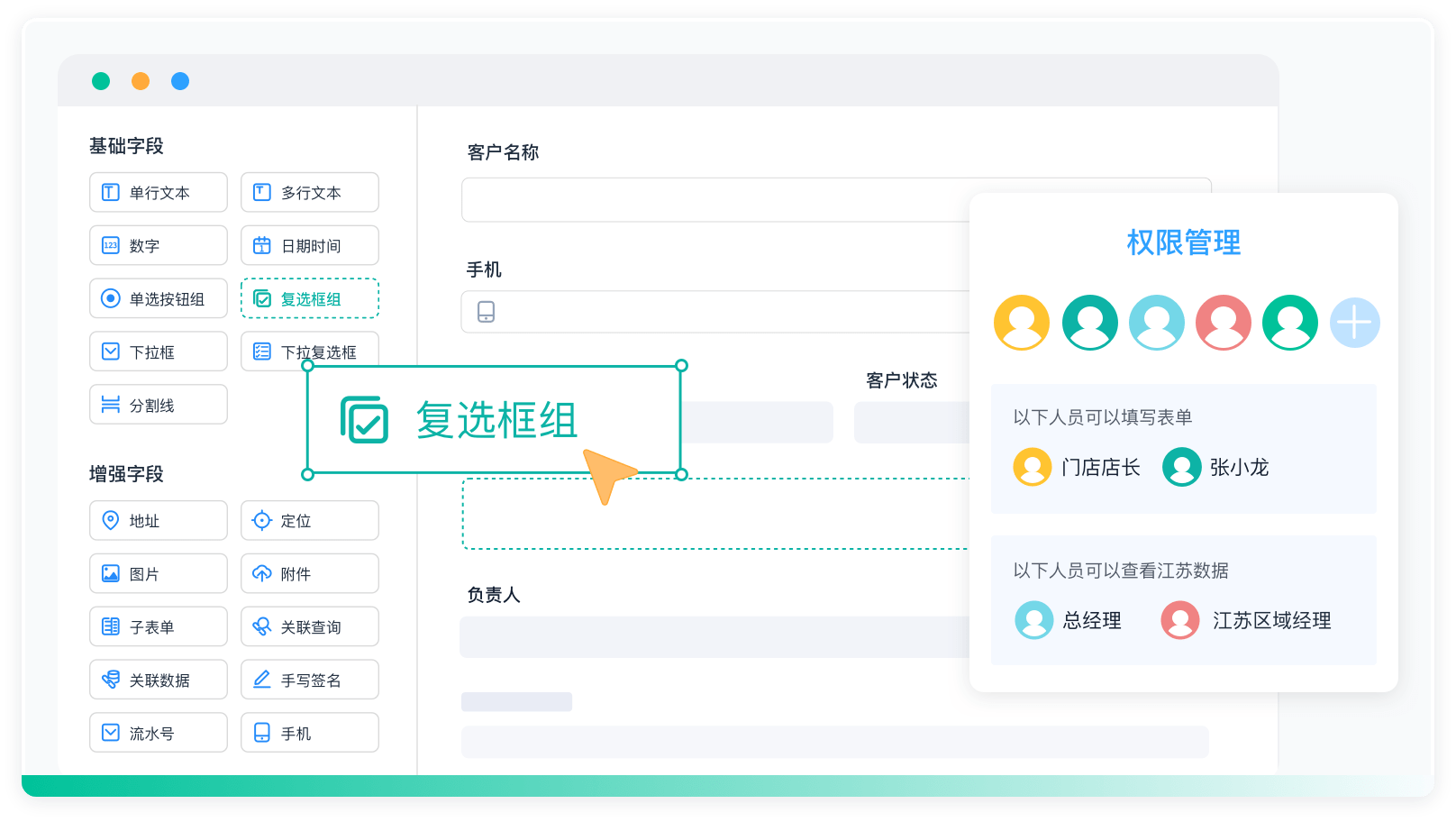

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

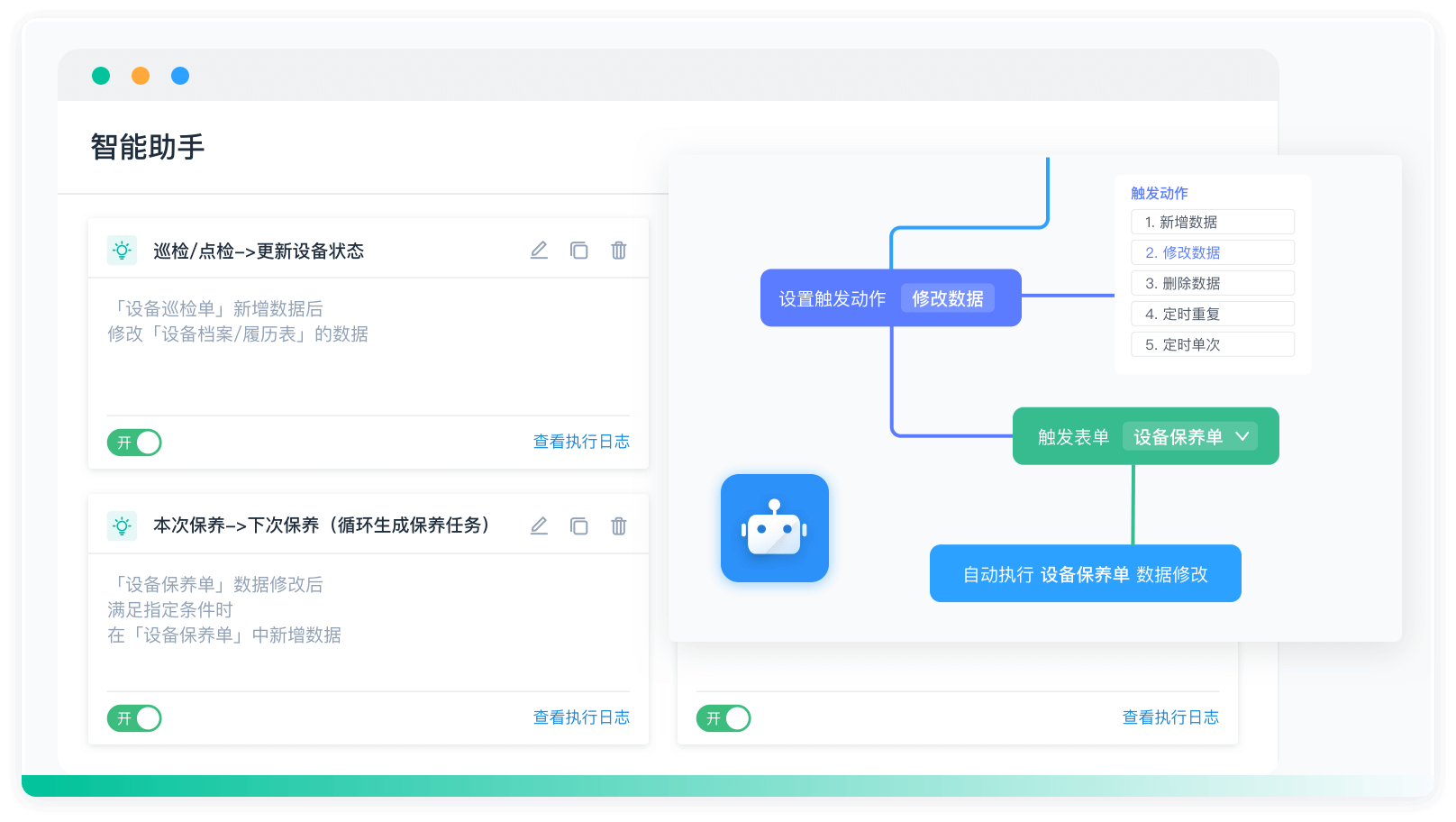

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理