生产管理软件 英文

-

已被采纳为最佳回答

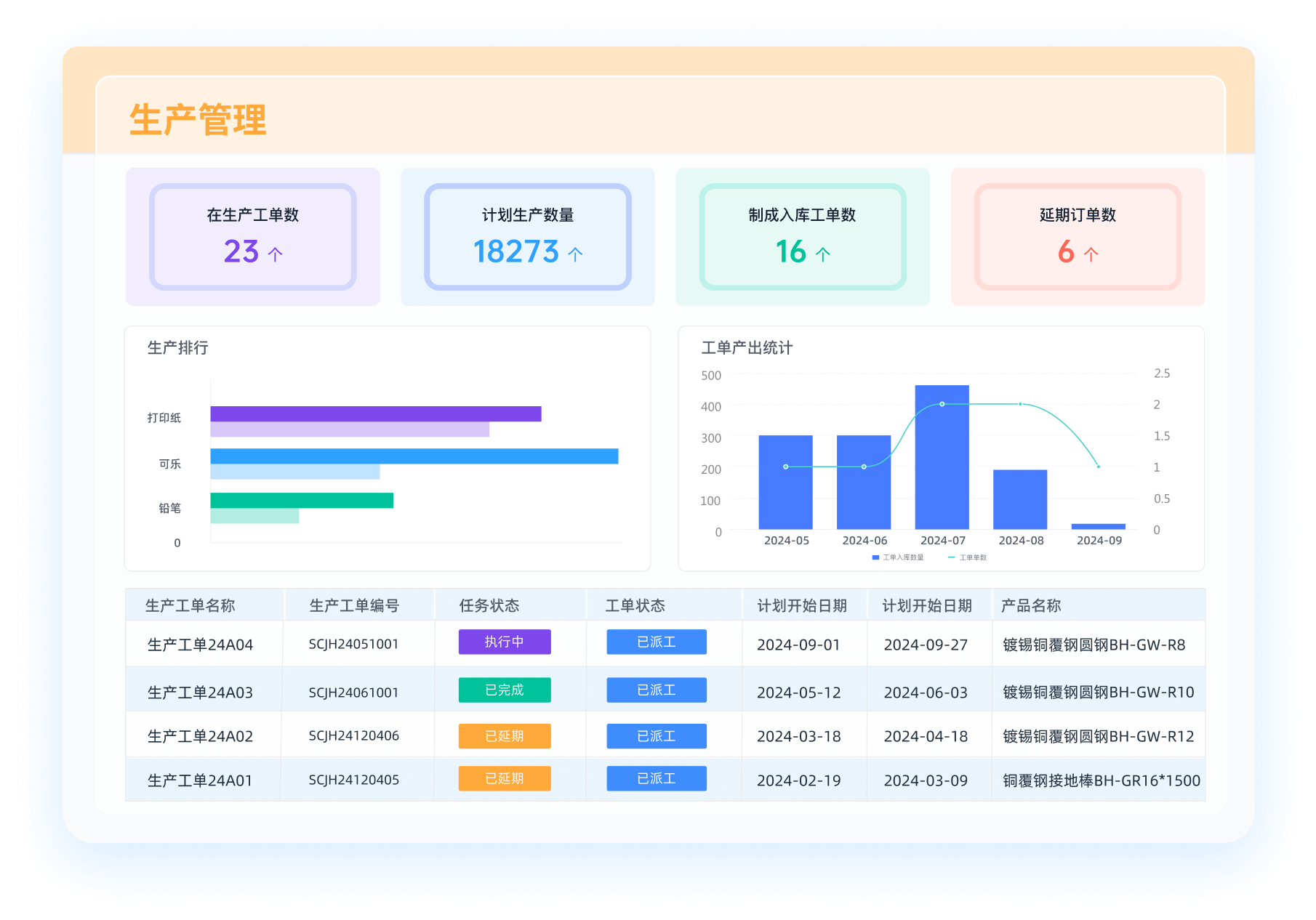

生产管理软件的英文称为“Production Management Software”,其主要功能包括提高生产效率、优化资源配置、实时监控生产流程。 在现代制造业中,生产管理软件的核心作用在于整合和分析生产数据,帮助企业做出及时的决策。通过实时监控,管理者可以迅速识别生产瓶颈,调整生产计划,从而有效减少停工时间和资源浪费。此外,这类软件通常还具备自动化报告功能,能够为管理层提供深入的生产分析,帮助企业实现精细化管理和持续改进。

一、生产管理软件的基本概念

生产管理软件是指用于计划、调度、跟踪和控制生产过程的一种系统工具。这类软件的设计目的是为了帮助企业提高生产效率和降低成本。它集成了生产计划、物料管理、质量控制等多个功能,能够实现生产过程的全生命周期管理。通过对生产数据的实时监控,生产管理软件不仅能够提高生产作业的透明度,还可以为管理层提供决策支持。

二、生产管理软件的主要功能

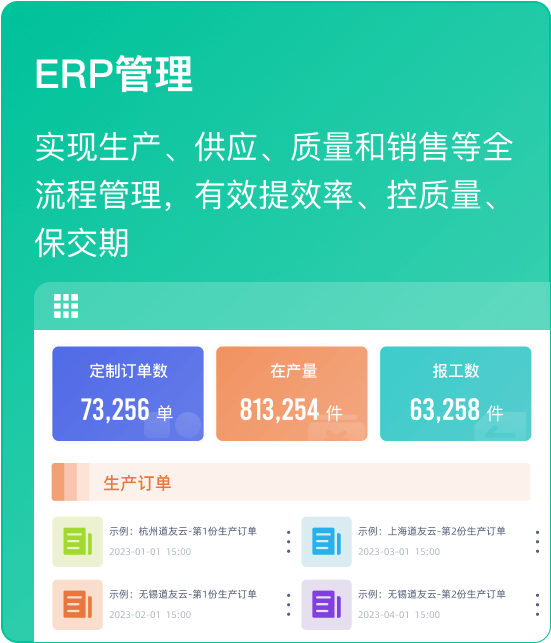

1. 生产计划与调度:生产管理软件可以根据订单需求、生产能力和物料供应情况,自动生成生产计划和调度方案。通过优化生产流程,企业能够确保按时交付,提高客户满意度。

2. 物料管理:有效的物料管理是生产效率的关键。生产管理软件能够实时跟踪物料库存,自动补货,避免因物料短缺而导致的生产延误。

3. 质量控制:质量是企业竞争力的核心。通过集成质量管理模块,生产管理软件能够实时监控生产过程中的质量指标,及时发现问题并进行纠正,确保最终产品的质量符合标准。

4. 数据分析与报告:现代生产管理软件通常具备强大的数据分析能力。通过对历史生产数据的分析,企业可以识别出生产瓶颈、成本高企的环节,从而制定相应的改进措施。

三、生产管理软件的实施步骤

1. 需求分析:在实施生产管理软件之前,企业需要进行详细的需求分析。明确生产流程中的痛点、目标和预期效果,为后续的系统选择和配置提供依据。

2. 系统选择:根据需求分析的结果,企业可以选择合适的生产管理软件。市场上有多种软件可供选择,企业应该根据自身规模、行业特点和预算进行综合评估。

3. 系统配置与集成:选择好软件后,需要进行系统配置和其他相关系统的集成。这一步骤非常关键,合理的配置能够最大化软件的功能,提升使用效率。

4. 用户培训:软件实施后,必须对用户进行培训,以确保他们能够熟练掌握系统的操作。这不仅能提高系统的使用率,还能帮助企业更快地实现预期收益。

5. 持续优化:生产管理软件的实施不是一蹴而就的,企业应根据实际使用情况,不断优化系统设置和流程,确保其能够适应不断变化的市场环境。

四、生产管理软件的市场趋势

1. 云计算的发展:随着云计算技术的普及,越来越多的企业开始转向云端的生产管理软件。这种转变不仅降低了企业的IT成本,还提高了系统的灵活性和可扩展性。

2. 人工智能的应用:人工智能技术的进步使得生产管理软件能够实现更为复杂的数据分析和预测。通过机器学习算法,软件可以根据历史数据预测未来的生产需求,帮助企业做出更为科学的决策。

3. 物联网的整合:物联网技术的应用使得生产设备能够实时连接到互联网,生产管理软件能够实时获取设备状态和生产数据,从而实现更为精准的生产监控和管理。

4. 移动端支持:随着移动设备的普及,越来越多的生产管理软件开始支持移动端操作。管理者可以随时随地通过手机或平板查看生产状态,进行决策和调整,提升管理效率。

五、选择生产管理软件的注意事项

1. 功能完整性:选择软件时,企业应评估其功能是否满足实际需求。例如,生产计划、物料管理、质量控制等功能是否齐全,是否支持企业未来的扩展需求。

2. 用户友好性:软件的操作界面应简洁易用,能够降低培训成本,提升用户的使用体验。复杂的操作流程可能导致员工的抵触情绪,影响软件的实施效果。

3. 服务与支持:选择软件供应商时,企业应关注其提供的售后服务和技术支持。良好的服务保障能够在系统出现问题时,及时得到解决,确保生产流程的连续性。

4. 成本效益:生产管理软件的成本不仅包括软件本身的购买费用,还包括后续的维护成本、培训费用等。企业应综合评估软件的性价比,确保投资回报率最大化。

六、生产管理软件的案例分析

在某大型制造企业的实施案例中,该企业原本面临生产流程不透明、物料短缺频繁等问题。通过引入一款先进的生产管理软件,该企业实现了生产计划的自动化,物料管理的精细化。软件的实时数据分析功能,使得管理层能够迅速识别生产瓶颈,调整生产策略。经过几个月的运行,企业的生产效率提高了30%,交货准时率提升至95%以上,客户满意度显著提升。此案例证明了生产管理软件在提升企业竞争力方面的重要作用。

七、总结与展望

生产管理软件在现代制造业中扮演着越来越重要的角色。随着科技的不断进步,未来的生产管理软件将会更加智能化、灵活化,能够更好地适应快速变化的市场需求。企业应抓住这一趋势,积极引入先进的生产管理软件,以提升自身的生产效率和市场竞争力。通过合理的实施和持续的优化,企业能够实现更高效的资源配置,推动可持续发展。

1年前 -

Production Management Software

Introduction

Production management software is a digital tool designed to streamline and optimize the manufacturing process in various industries. This software assists in planning, organizing, and controlling the production activities to ensure efficiency, quality, and timely delivery of goods. In this article, we will explore the key features, benefits, and implementation of production management software.Key Features of Production Management Software

-

Inventory Management

Production management software helps in managing raw materials, work-in-progress inventory, and finished goods. It provides real-time tracking of inventory levels, reorder points, and inventory costs. This feature enables manufacturers to optimize inventory levels, reduce stockouts, and avoid overstocking. -

Production Planning and Scheduling

The software facilitates production planning by creating detailed schedules for each manufacturing process. It considers factors such as machine capacity, resource availability, lead times, and order priorities to create an optimized production schedule. This helps in balancing workloads, reducing bottlenecks, and meeting production deadlines. -

Quality Control

Quality control is a critical aspect of production management software. It allows manufacturers to define quality standards, conduct inspections at various stages of production, and identify defects early in the process. By maintaining quality standards, manufacturers can reduce rework, minimize defects, and improve customer satisfaction. -

Maintenance Management

Production management software includes maintenance management features to ensure that equipment and machinery are properly maintained. It helps in scheduling preventive maintenance tasks, tracking equipment downtime, and managing spare parts inventory. By proactively maintaining equipment, manufacturers can minimize breakdowns and disruptions in production. -

Cost Tracking and Analysis

Cost tracking and analysis features enable manufacturers to monitor production costs, analyze cost trends, and identify areas for cost savings. The software provides insights into labor costs, material costs, overhead costs, and production variances. By analyzing cost data, manufacturers can make informed decisions to improve profitability. -

Reporting and Analytics

Production management software offers reporting and analytics tools to generate customized reports, dashboards, and key performance indicators (KPIs). Manufacturers can track production metrics such as efficiency, utilization, yield, and cycle times. Analyzing production data helps in identifying trends, optimizing processes, and making data-driven decisions.

Benefits of Production Management Software

-

Improved Efficiency

Production management software streamlines production processes, reduces manual tasks, and eliminates inefficiencies. By automating repetitive tasks, manufacturers can improve productivity, reduce lead times, and increase throughput. -

Enhanced Visibility

Production management software provides real-time visibility into production activities, inventory levels, and order statuses. Manufacturers can track the progress of each job, identify bottlenecks, and make adjustments to optimize production flow. -

Better Resource Utilization

The software helps in optimizing resource utilization by allocating resources effectively, balancing workloads, and minimizing idle time. Manufacturers can schedule production tasks based on resource availability and capacity, leading to improved efficiency and cost savings. -

Quality Assurance

By implementing quality control measures and inspections, production management software ensures that products meet quality standards and customer requirements. This leads to fewer defects, reduced rework, and increased customer satisfaction. -

Cost Savings

Production management software helps in reducing production costs by optimizing inventory levels, minimizing waste, and improving resource utilization. By analyzing production data and identifying cost-saving opportunities, manufacturers can increase profitability and competitiveness.

Implementation of Production Management Software

-

Assessing Needs

Before implementing production management software, manufacturers should assess their specific needs, challenges, and goals. They should identify key requirements such as inventory management, production planning, quality control, and reporting. -

Selecting the Right Software

Manufacturers should research and evaluate different production management software solutions available in the market. They should consider factors such as features, scalability, ease of use, integration capabilities, and vendor reputation before making a decision. -

Training and Onboarding

Once the software is selected, manufacturers should provide training to employees on how to use the software effectively. Training sessions should cover basic functionalities, best practices, and troubleshooting tips to ensure a smooth transition to the new system. -

Data Migration

Manufacturers need to migrate existing data such as inventory records, production schedules, and quality control data to the new software. Data migration should be carefully planned and executed to prevent data loss or inconsistencies. -

Testing and Optimization

Before fully implementing the software, manufacturers should conduct thorough testing to ensure that all features work as expected. They should identify any issues, bugs, or performance bottlenecks and work with the software vendor to resolve them. Continuous optimization is essential to maximize the benefits of the software. -

Continuous Improvement

Production management software is not a one-time solution but a tool for continuous improvement. Manufacturers should regularly review production processes, analyze performance data, and identify areas for optimization. By leveraging the insights provided by the software, manufacturers can enhance productivity, quality, and profitability.

Conclusion

Production management software plays a crucial role in modern manufacturing operations by improving efficiency, quality, and cost-effectiveness. By leveraging the key features and benefits of production management software, manufacturers can optimize production processes, meet customer demands, and stay competitive in the market. Implementation of production management software requires careful planning, training, and continuous improvement to realize its full potential.1年前 -

-

Manufacturing Management Software

Manufacturing management software, also known as production management software, is a type of software designed to assist in the planning, tracking, and controlling of production processes in a manufacturing environment. This software provides tools for managing tasks such as inventory control, resource planning, production scheduling, quality control, and maintenance management.

The primary goal of manufacturing management software is to optimize the production process, reduce costs, improve efficiency, and ensure that products are delivered on time and meet quality standards. By automating and streamlining various aspects of production management, this software helps manufacturing companies to operate more effectively and competitively in today's fast-paced business environment.

Key Features of Manufacturing Management Software:

-

Inventory Management: Manufacturing management software helps companies keep track of raw materials, work-in-progress inventory, and finished goods inventory. It provides real-time visibility into inventory levels, helps prevent stockouts or overstock situations, and enables efficient procurement and replenishment processes.

-

Production Scheduling: This software allows production managers to create and manage production schedules based on factors such as available resources, order priorities, and lead times. It helps optimize production workflows, minimize idle time, and meet delivery deadlines.

-

Resource Planning: Manufacturing management software assists in allocating resources such as equipment, machinery, and manpower effectively. It helps optimize resource utilization, balance workloads, and identify potential bottlenecks in the production process.

-

Quality Control: Quality management modules in manufacturing management software enable companies to monitor and maintain product quality throughout the production cycle. These modules provide tools for inspections, testing, and compliance tracking to ensure that products meet regulatory standards and customer requirements.

-

Maintenance Management: Manufacturing equipment requires regular maintenance to operate efficiently and prevent unexpected breakdowns. Manufacturing management software includes maintenance management features to schedule preventive maintenance tasks, track equipment downtime, and manage maintenance workflows.

-

Reporting and Analytics: Manufacturing management software generates reports and dashboards that provide insights into key performance indicators (KPIs) such as production efficiency, yield rates, and production costs. These analytics help management make data-driven decisions to improve operational performance.

Benefits of Manufacturing Management Software:

-

Improved Efficiency: By automating manual tasks and streamlining production processes, manufacturing management software helps companies operate more efficiently and reduce lead times.

-

Cost Savings: Optimal resource utilization, inventory control, and production scheduling provided by the software help reduce operational costs and minimize waste.

-

Enhanced Visibility: Real-time data and analytics offered by manufacturing management software provide visibility into production operations, enabling better decision-making and proactive problem-solving.

-

Compliance and Quality Assurance: Quality control and compliance tracking features help ensure that products meet regulatory requirements and quality standards, enhancing customer satisfaction and brand reputation.

-

Scalability: Manufacturing management software is scalable and can adapt to the changing needs of a growing manufacturing business, supporting expansion and diversification.

In conclusion, manufacturing management software plays a crucial role in helping manufacturing companies streamline their production processes, improve efficiency, and stay competitive in the market. By leveraging the features and benefits of this software, manufacturers can optimize their operations, reduce costs, and deliver high-quality products to meet customer demands.

1年前 -

-

The English term for "生产管理软件" is "Production Management Software." Production management software is a type of technology that helps businesses plan, track, and control manufacturing processes. This software is designed to streamline operations, improve efficiency, and increase productivity in a production environment. Here are five key points about production management software:

-

Features: Production management software typically includes features such as production planning, scheduling, inventory management, quality control, and reporting. It allows users to create production schedules, track work orders, manage materials and resources, monitor product quality, and generate performance reports.

-

Benefits: Production management software offers several benefits to businesses, including increased efficiency, reduced costs, improved quality control, and better decision-making. By automating production processes and providing real-time data insights, this software helps organizations optimize their operations and respond quickly to changing market conditions.

-

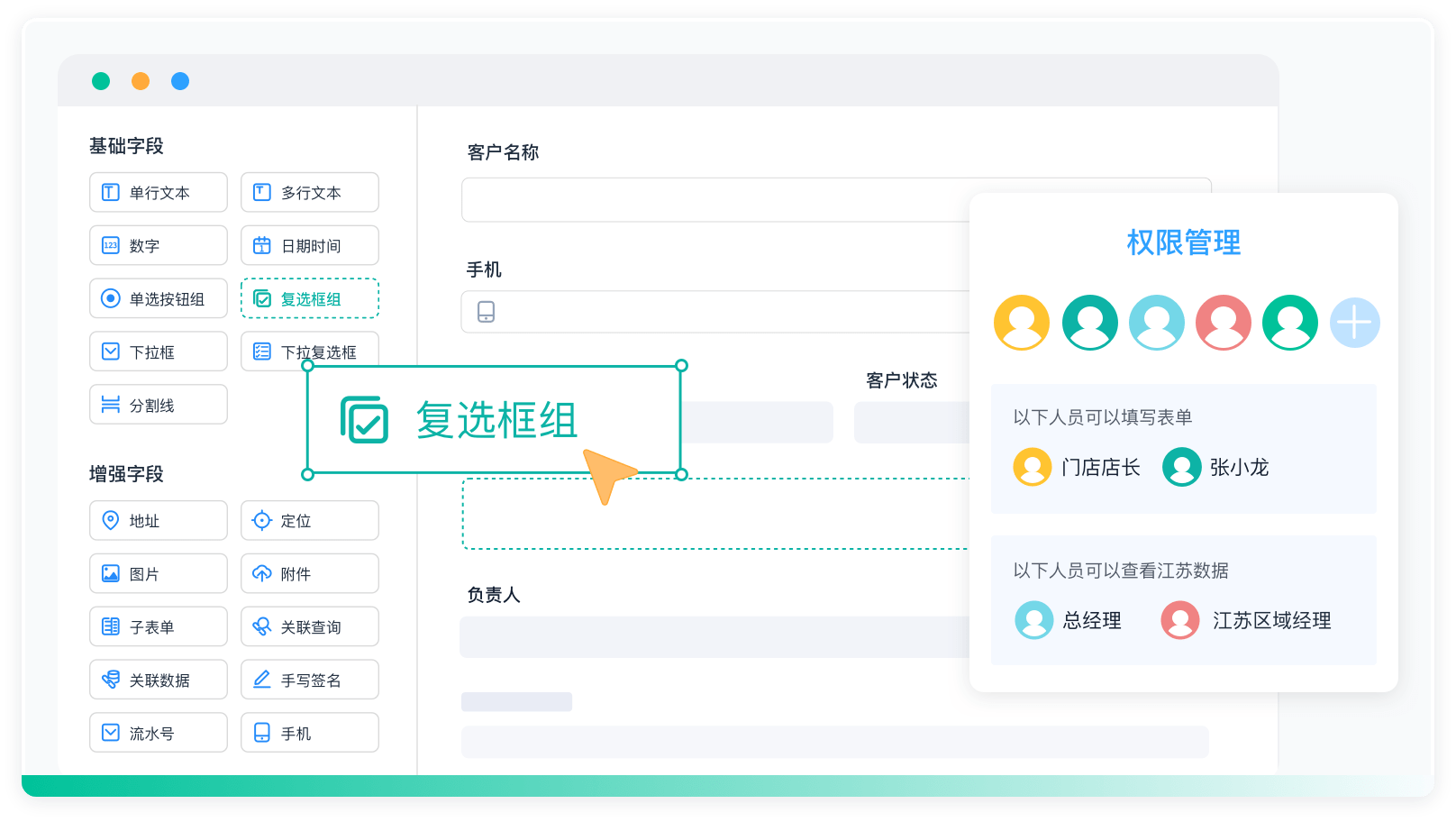

Integration: Production management software can be integrated with other business systems, such as enterprise resource planning (ERP) software, customer relationship management (CRM) software, and supply chain management systems. This integration enables seamless data flow across different departments and improves overall visibility and coordination within the organization.

-

Customization: Many production management software solutions offer customization options to meet the specific needs of different industries and businesses. Users can tailor the software to their unique production processes, workflows, and reporting requirements, ensuring that it aligns with their operational goals and objectives.

-

Trends: The production management software market is constantly evolving, with new trends such as the adoption of cloud-based solutions, the integration of Internet of Things (IoT) technology, and the use of artificial intelligence and machine learning algorithms for predictive analytics. These trends are shaping the future of production management software and driving innovation in the industry.

Overall, production management software plays a crucial role in helping businesses optimize their manufacturing processes, improve productivity, and stay competitive in today's dynamic market environment. By leveraging the capabilities of this technology, organizations can achieve operational excellence and meet the demands of modern production management.

1年前 -

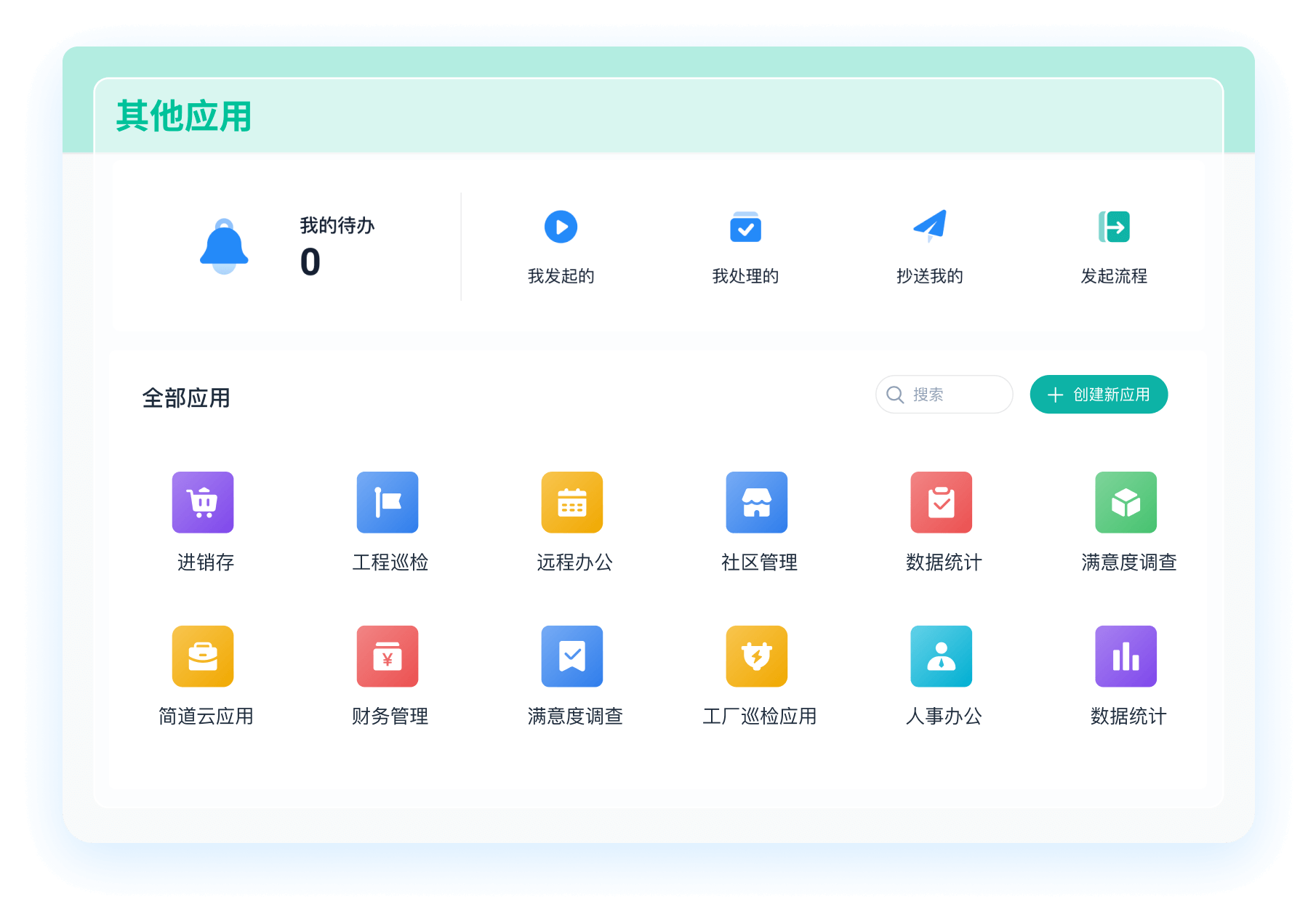

《零代码开发知识图谱》

《零代码开发知识图谱》

《零代码

新动能》案例集

《零代码

新动能》案例集

《企业零代码系统搭建指南》

《企业零代码系统搭建指南》

领先企业,真实声音

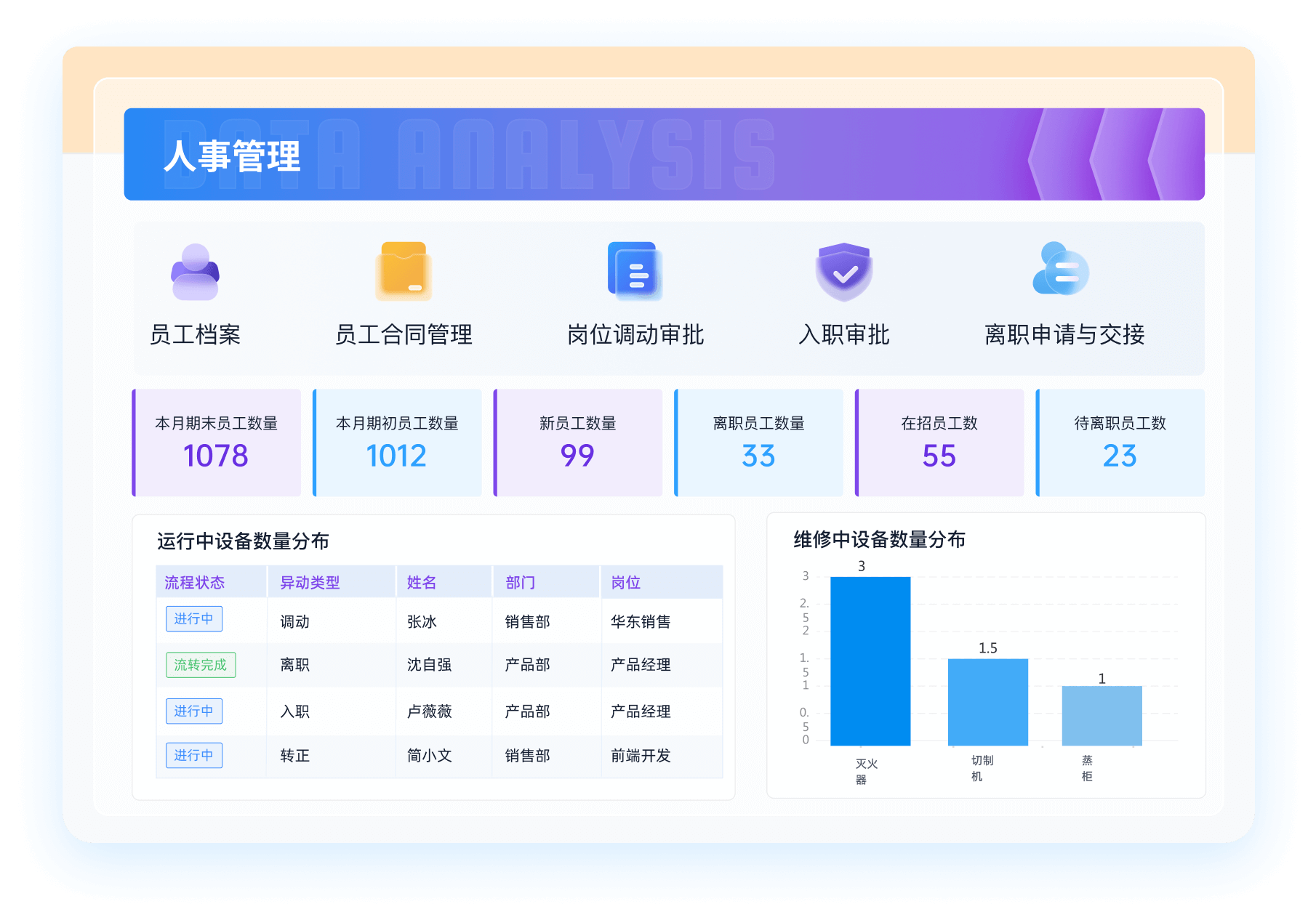

简道云让业务用户感受数字化的效果,加速数字化落地;零代码快速开发迭代提供了很低的试错成本,孵化了一批新工具新方法。

郑炯蒙牛乳业信息技术高级总监

简道云把各模块数据整合到一起,工作效率得到质的提升。现在赛艇协会遇到新的业务需求时,会直接用简道云开发demo,基本一天完成。

谭威正中国赛艇协会数据总监

业务与技术交织,让思维落地实现。四年简道云使用经历,功能越来越多也反推业务流程转变,是促使我们成长的过程。实现了真正降本增效。

袁超OPPO(苏皖)信息化部门负责人

零代码的无门槛开发方式盘活了全公司信息化推进的热情和效率,简道云打破了原先集团的数据孤岛困局,未来将继续向数据要生产力。

伍学纲东方日升新能源股份有限公司副总裁

通过简道云零代码技术的运用实践,提高了企业转型速度、减少对高技术专业人员的依赖。在应用推广上,具备员工上手快的竞争优势。

董兴潮绿城建筑科技集团信息化专业经理

简道云是目前最贴合我们实际业务的信息化产品。通过灵活的自定义平台,实现了信息互通、闭环管理,企业管理效率真正得到了提升。

王磊克吕士科学仪器(上海)有限公司总经理